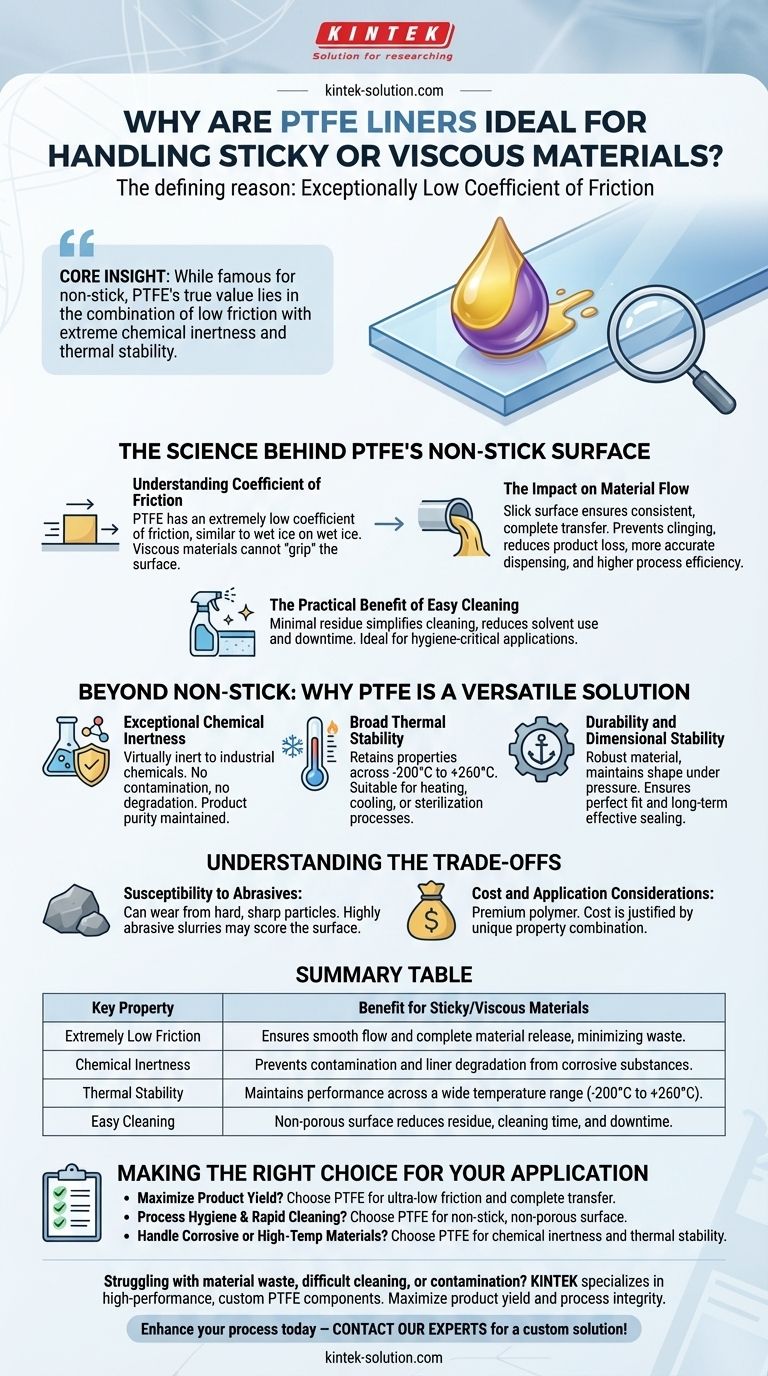

The defining reason PTFE liners are ideal for handling sticky or viscous materials is their exceptionally low coefficient of friction. This property, one of the lowest of any solid material, creates a surface so slick that other substances have virtually nothing to adhere to, ensuring smooth flow and easy release.

The core insight is that while PTFE's famous non-stick quality is the immediate solution for viscous materials, its true value lies in the combination of this property with its extreme chemical inertness and thermal stability, making it a uniquely reliable choice for demanding industrial and scientific processes.

The Science Behind PTFE's Non-Stick Surface

To understand why PTFE (Polytetrafluoroethylene) outperforms other materials, we must look at its fundamental properties. It isn't just a coating; it's a material engineered for minimal interaction.

Understanding Coefficient of Friction

The coefficient of friction is a measure of how much force it takes to slide one surface over another. PTFE has an extremely low value, similar to wet ice on wet ice.

This means that even sticky, viscous materials lack the ability to "grip" the liner's surface. They slide off effortlessly under gravity or light pressure.

The Impact on Material Flow

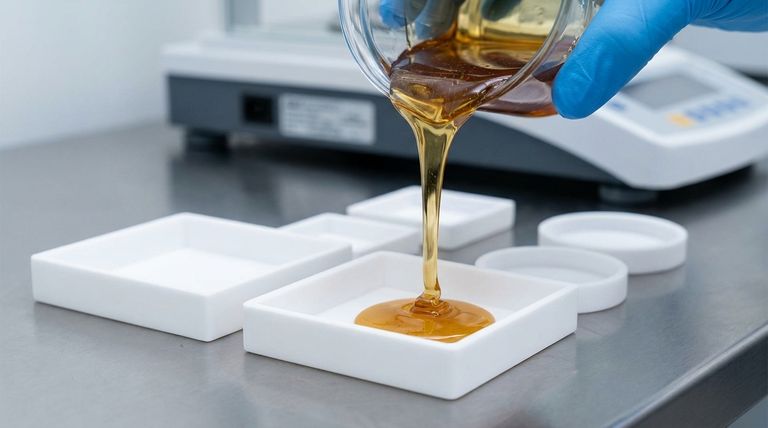

This slick surface ensures a consistent and complete transfer of material. It prevents product from clinging to the walls of containers, pipes, or vessels.

This directly translates to reduced product loss, more accurate dispensing, and higher process efficiency.

The Practical Benefit of Easy Cleaning

Because materials cannot easily adhere to the PTFE surface, cleaning is drastically simplified. Residue is minimal, which reduces cleaning time, solvent use, and overall operational downtime.

This makes it an ideal choice for applications where hygiene and rapid batch turnover are critical, such as in food processing or pharmaceuticals.

Beyond Non-Stick: Why PTFE is a Versatile Solution

A material's suitability is never about a single property. PTFE's effectiveness comes from a powerful combination of traits that allow it to function reliably in aggressive operating conditions.

Exceptional Chemical Inertness

PTFE is virtually inert, meaning it does not react with the vast majority of industrial chemicals.

This guarantees that the liner will not contaminate the material it contains, nor will it degrade from exposure to corrosive substances. Product purity is maintained.

Broad Thermal Stability

PTFE retains its key properties across an exceptionally wide temperature range, from cryogenic lows to high-heat applications.

This versatility allows it to be used in processes involving heating, cooling, or sterilization without losing its structural integrity or non-stick performance.

Durability and Dimensional Stability

Despite its slick surface, PTFE is a robust material that maintains its shape and strength. This dimensional stability ensures that liners fit perfectly and seals remain effective over time, even under pressure.

Understanding the Trade-offs

No material is perfect for every scenario. Being an effective advisor means acknowledging the limitations of even the best solutions.

Susceptibility to Abrasives

While excellent for viscous liquids and pastes, PTFE can be susceptible to wear from hard, sharp particles. Highly abrasive slurries can potentially score the surface over time, diminishing its non-stick properties.

Cost and Application Considerations

PTFE is a premium performance polymer. Its cost can be higher than other plastics, so its use is typically justified in applications where its unique combination of properties is a critical requirement.

Making the Right Choice for Your Application

Selecting the right liner depends entirely on the primary goal of your process.

- If your primary focus is maximizing product yield: The ultra-low friction of PTFE is the key benefit, as it ensures the most complete transfer of viscous materials with minimal waste.

- If your primary focus is process hygiene and rapid cleaning: The non-stick, non-porous surface of PTFE is paramount, preventing residue buildup and drastically reducing cleaning validation time.

- If your primary focus is handling corrosive or high-temperature materials: PTFE's chemical inertness and thermal stability are the deciding factors, guaranteeing process integrity where other materials would fail.

Understanding these core principles empowers you to select materials with confidence, ensuring the efficiency and reliability of your operations.

Summary Table:

| Key Property | Benefit for Sticky/Viscous Materials |

|---|---|

| Extremely Low Friction | Ensures smooth flow and complete material release, minimizing waste. |

| Chemical Inertness | Prevents contamination and liner degradation from corrosive substances. |

| Thermal Stability | Maintains performance across a wide temperature range (-200°C to +260°C). |

| Easy Cleaning | Non-porous surface reduces residue, cleaning time, and downtime. |

Struggling with material waste, difficult cleaning, or contamination in your process? KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision-engineered PTFE solutions ensure maximum product yield, process integrity, and operational efficiency. Whether you need a prototype or high-volume production, we deliver reliability tailored to your demanding applications.

Enhance your process today—contact our experts for a custom solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- When and by whom was PTFE discovered? A Tale of Accidental Innovation