The cost-effectiveness of PTFE liners stems from their exceptional durability and minimal long-term maintenance needs. While the initial purchase price may be higher than some alternatives, their resistance to wear, harsh chemicals, and extreme conditions dramatically reduces the total cost of ownership. This translates into fewer replacements, less operational downtime, and lower maintenance overhead throughout the component's lifespan.

The core principle is a shift in perspective from upfront purchase price to total cost of ownership. PTFE's value is not in being the cheapest option initially, but in being the most economical solution over the long term by virtually eliminating the hidden costs of maintenance, replacement, and downtime.

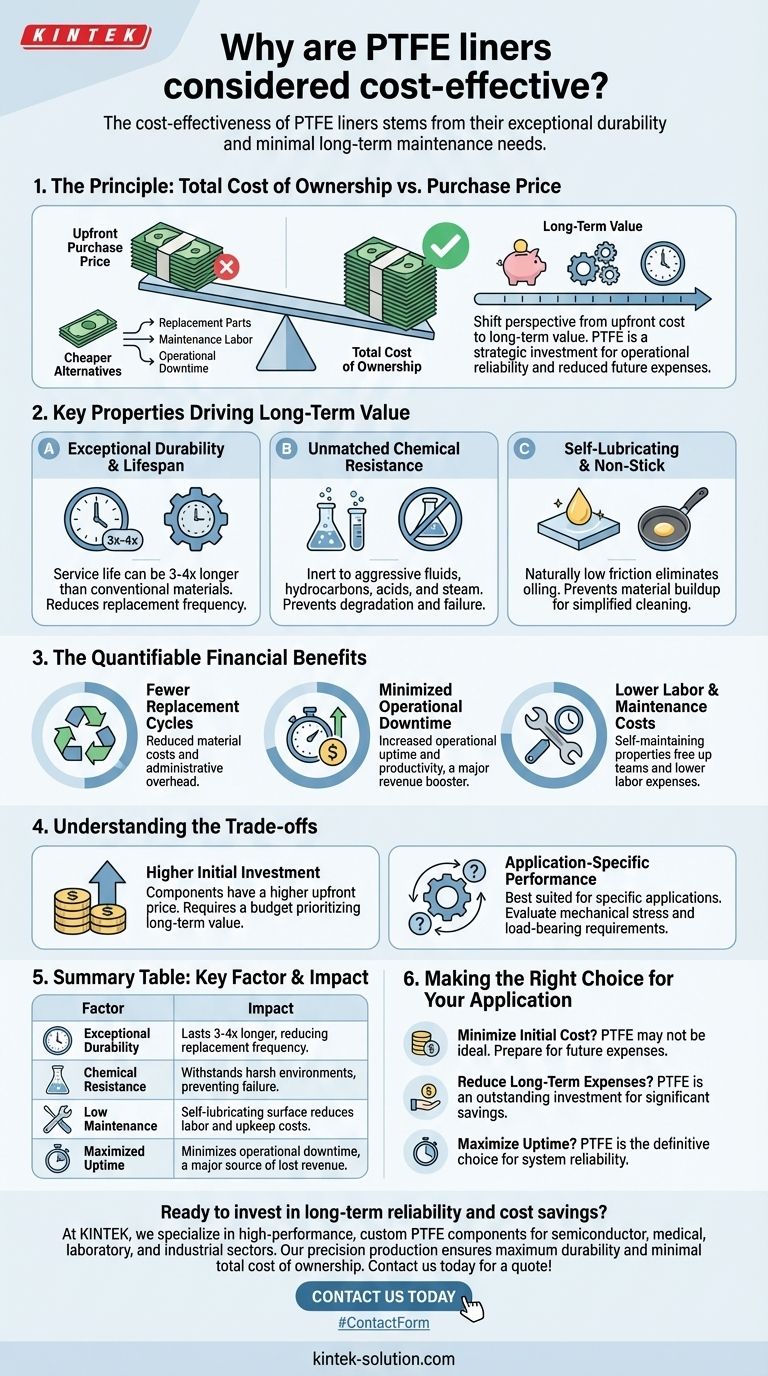

The Principle: Total Cost of Ownership vs. Purchase Price

When evaluating industrial components, focusing solely on the initial price tag can be misleading. A more accurate financial analysis considers the total cost of ownership over the component's entire service life.

Shifting Focus from Upfront Cost

Materials like PTFE are best viewed as a long-term investment. Their higher initial cost is offset by significant savings in other areas. This is a strategic decision to prioritize operational reliability and reduce future expenses.

The Hidden Costs of Cheaper Alternatives

Less durable materials often carry significant hidden costs. These include the expense of frequent replacement parts, the labor required for installation and ongoing maintenance, and—most critically—the cost of operational downtime during repairs.

Key Properties Driving Long-Term Value

PTFE's cost-effectiveness is not a single feature but the result of a combination of its unique material properties.

Exceptional Durability and Lifespan

PTFE is highly resistant to wear and tear, giving it a service life that can be three to four times longer than conventional materials in similar applications. This fundamental durability is the primary driver of its long-term value, as it drastically reduces the frequency of replacement cycles.

Unmatched Chemical Resistance

PTFE is chemically inert to a wide range of aggressive fluids, including hydrocarbons, acids, solvents, and steam. This resilience prevents degradation and failure in harsh industrial environments where other materials would quickly break down.

Self-Lubricating and Non-Stick Surface

The material's naturally low coefficient of friction means it is self-lubricating, eliminating the need for regular oiling. Its non-stick surface prevents the buildup of process materials, which simplifies cleaning and maintains system efficiency.

Understanding the Trade-offs

No material is perfect for every application. Being objective about PTFE requires understanding its primary trade-off.

The Higher Initial Investment

The most significant consideration is that components made from PTFE often have a higher upfront purchase price compared to those made from other plastics or metals. This requires a budget that prioritizes long-term value over minimal initial outlay.

Application-Specific Performance

While incredibly versatile, the mechanical properties of PTFE mean it is best suited for specific applications. Factors like extreme mechanical stress or load-bearing requirements must be carefully evaluated to ensure it is the right choice.

The Quantifiable Financial Benefits

The long-term value of PTFE can be measured in direct, quantifiable savings that impact the bottom line.

Fewer Replacement Cycles

A longer service life directly translates to buying fewer replacement parts over time. This reduces not only material costs but also the associated administrative and logistical overhead.

Minimized Operational Downtime

For any industrial process, downtime is a significant source of lost revenue. Because PTFE components fail less frequently, they contribute to greater operational uptime and productivity, which is often the largest financial benefit.

Lower Labor and Maintenance Costs

The self-maintaining properties of PTFE—such as being self-lubricating and easy to clean—reduce the person-hours required for upkeep. This frees up maintenance teams to focus on other critical tasks and lowers overall labor expenses.

Making the Right Choice for Your Application

To determine if PTFE is the right choice, align the material's strengths with your primary operational goals.

- If your primary focus is minimizing initial project cost: PTFE may not be the ideal choice, as its upfront price is higher. Be prepared, however, for potentially greater long-term maintenance and replacement expenses.

- If your primary focus is reducing long-term operational expenses: PTFE is an outstanding investment. Its longevity and low-maintenance nature will deliver significant savings over the life of the equipment.

- If your primary focus is maximizing uptime in harsh environments: PTFE's superior chemical resistance and durability make it the definitive choice for ensuring system reliability and preventing costly, unscheduled shutdowns.

Ultimately, selecting PTFE is a strategic investment in operational stability and long-term financial efficiency.

Summary Table:

| Key Factor | Impact on Cost-Effectiveness |

|---|---|

| Exceptional Durability | Lasts 3-4x longer than alternatives, reducing replacement frequency. |

| Chemical Resistance | Withstands harsh environments, preventing degradation and failure. |

| Low Maintenance | Self-lubricating and non-stick surface reduces labor and upkeep costs. |

| Maximized Uptime | Minimizes operational downtime, a major source of lost revenue. |

Ready to invest in long-term reliability and cost savings for your operations?

At KINTEK, we specialize in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your components deliver maximum durability and minimal total cost of ownership.

Whether you need a prototype or a high-volume order, we can fabricate the perfect PTFE solution to enhance your operational efficiency. Contact us today to discuss your specific requirements and receive a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the primary materials used for oil seals? NBR vs. PTFE for Your Application

- Why are Teflon bushings essential for machinery? Reduce Friction, Maintenance, and Costs

- What are O-rings and why are they commonly used? A Guide to Simple, Reliable Sealing

- What flange types are PTFE envelope gaskets compatible with? Versatile Sealing for Every Industry

- In which industries are PTFE/PFA lined ball valves commonly used? Essential for Corrosive & High-Purity Fluids

- What are the benefits of PTFE bushes over plastic bushings? Superior Performance for Harsh Environments

- What toolpath strategies benefit thin-wall PTFE machining? Master Precision with Helical Paths and Low-Stress Techniques

- What are the limitations of PTFE oil seals, and how are they addressed? Overcome Material Challenges with Engineered Solutions