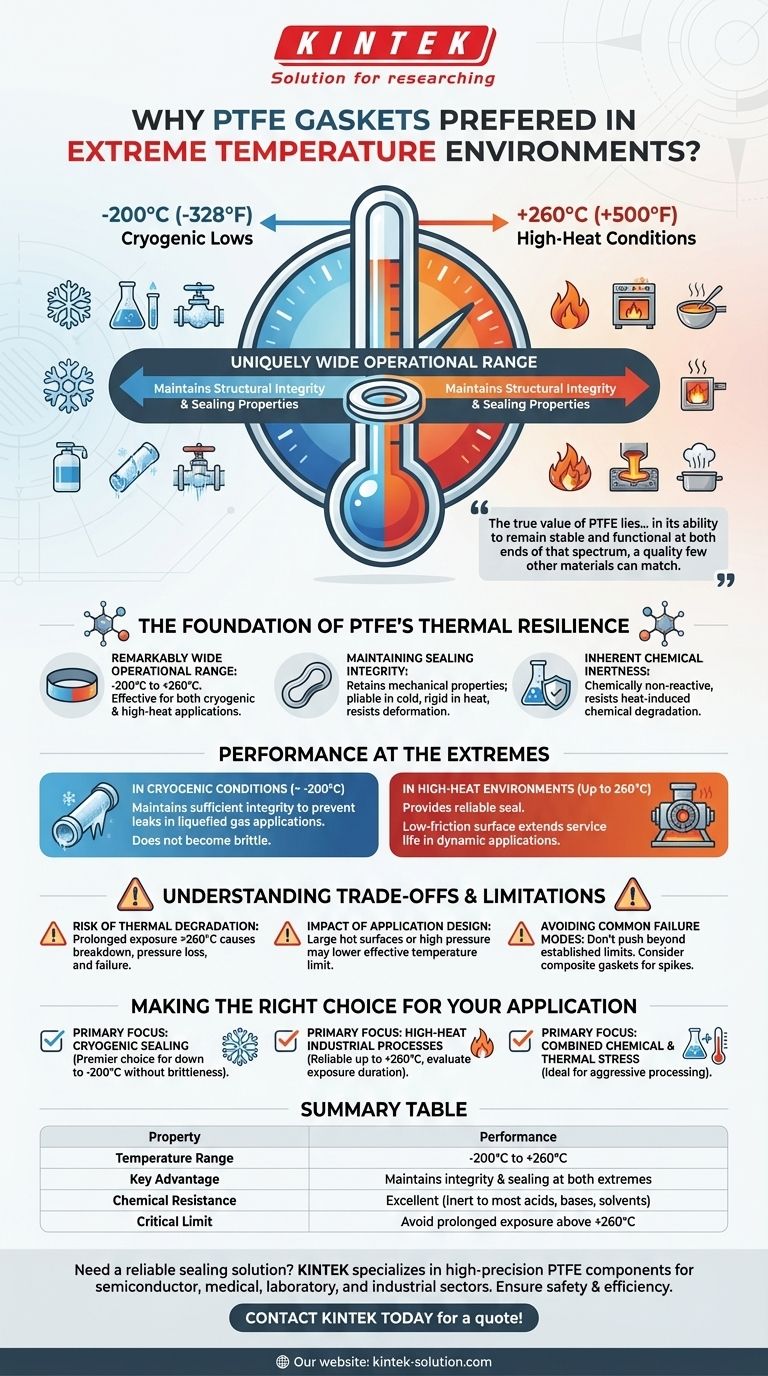

To put it simply, PTFE gaskets are preferred in extreme temperature environments because of their uniquely wide operational range. They maintain their structural integrity and sealing properties from cryogenic lows of -200°C (-328°F) all the way up to high-heat conditions of +260°C (+500°F).

Choosing a gasket for extreme temperatures is a critical decision where failure is not an option. The true value of PTFE lies not just in its wide temperature tolerance, but in its ability to remain stable and functional at both ends of that spectrum, a quality few other materials can match.

The Foundation of PTFE's Thermal Resilience

The preference for Polytetrafluoroethylene (PTFE), commonly known by the brand name Teflon, stems from its fundamental molecular structure. This structure gives it a combination of properties that are perfectly suited for environments where other materials would quickly fail.

A Remarkably Wide Operational Range

PTFE gaskets operate effectively within a temperature band of -200°C to +260°C. This makes them one of the few materials that can be specified for both cryogenic applications and high-temperature industrial processes without modification.

Maintaining Sealing Integrity

Unlike elastomers that can become brittle and crack in extreme cold or soften and extrude under high heat, PTFE retains its essential mechanical properties. It remains pliable enough to seal effectively at low temperatures and rigid enough to resist deformation at high temperatures.

Inherent Chemical Inertness

PTFE is one of the most chemically non-reactive materials known. This inertness is crucial because high temperatures can often accelerate chemical attacks. Because PTFE resists acids, bases, and solvents, it is less susceptible to heat-induced chemical degradation.

Performance at the Extremes

Understanding how PTFE behaves at the boundaries of its operational range is key to using it effectively. It doesn't just survive; it continues to perform its primary function.

In Cryogenic Conditions

At temperatures approaching -200°C, many materials lose all flexibility. PTFE, however, maintains sufficient integrity to prevent leaks in applications involving liquefied gases and other cryogenic fluids.

In High-Heat Environments

Up to its 260°C limit, PTFE provides a reliable seal. Its low-friction surface is an added benefit in dynamic applications, where high temperatures are often combined with high surface speeds or pressures, reducing wear and extending service life.

Understanding the Trade-offs and Limitations

No material is perfect, and objectivity requires acknowledging a material's limits. While exceptionally resilient, PTFE is not indestructible, and misapplication can lead to failure.

The Risk of Thermal Degradation

If exposed to temperatures prolonged or significantly above its +260°C rating, PTFE will begin to break down. This degradation can lead to a loss of sealing pressure and eventual gasket failure.

The Impact of Application Design

The maximum service temperature can be affected by other factors. In applications involving large, hot surface areas or high internal pressures, the effective temperature limit of the gasket may be lower. Always consider the entire system, not just the temperature.

Avoiding Common Failure Modes

The most common mistake is pushing PTFE beyond its established limits. If your application involves frequent temperature spikes above 260°C, a different material or a composite gasket (like a PTFE envelope gasket with a more heat-resistant core) may be necessary.

Making the Right Choice for Your Application

Use these guidelines to determine if PTFE is the optimal choice for your specific needs.

- If your primary focus is cryogenic sealing: PTFE is a premier choice due to its proven ability to maintain a seal without becoming brittle at temperatures down to -200°C.

- If your primary focus is high-heat industrial processes: PTFE is highly reliable for continuous use up to +260°C, but you must carefully evaluate the duration of heat exposure and the potential for over-temperature spikes.

- If your primary focus is combined chemical and thermal stress: PTFE's exceptional chemical inertness and thermal stability make it an ideal solution for aggressive chemical processing applications.

By understanding both the distinct advantages and the critical limits of PTFE, you can engineer a sealing solution that ensures safety and reliability in the most demanding environments.

Summary Table:

| Property | Performance |

|---|---|

| Temperature Range | -200°C to +260°C |

| Key Advantage | Maintains integrity & sealing at both extremes |

| Chemical Resistance | Excellent (Inert to most acids, bases, solvents) |

| Critical Limit | Avoid prolonged exposure above +260°C |

Need a reliable sealing solution for extreme temperatures? KINTEK specializes in manufacturing high-precision PTFE components, including gaskets, seals, and liners, for the semiconductor, medical, laboratory, and industrial sectors. We ensure your equipment operates safely and efficiently, even in the most demanding environments. From custom prototypes to high-volume orders, our expertise delivers the performance you require.

Contact KINTEK today to discuss your specific application needs and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the characteristics of Polytetrafluoroethylene (PTFE) with Carbon-Graphite Fill for aqueous fluid media? Enhance Sealing Performance

- What are the advantages of PTFE balls over metals or alloys? Superior Chemical & Friction Resistance

- What are the material options for PTFE O-ring seals? A Guide to High-Performance Filled PTFE Compounds

- How does a PTFE liner function in a spherical bearing or rod end? Achieve Maintenance-Free, Self-Lubricating Performance

- What are the key properties of Teflon bushings? Achieve Superior Performance in Demanding Industrial Environments

- What are the advantages of PTFE/PFA lining in steel pipes? Achieve Superior Corrosion Resistance and Purity

- How does the structure of ePTFE gaskets improve upon standard PTFE? Solve Creep and Cold Flow for Superior Seals

- What are the advantages of Teflon encapsulated o-rings? Superior Chemical & Temperature Resistance