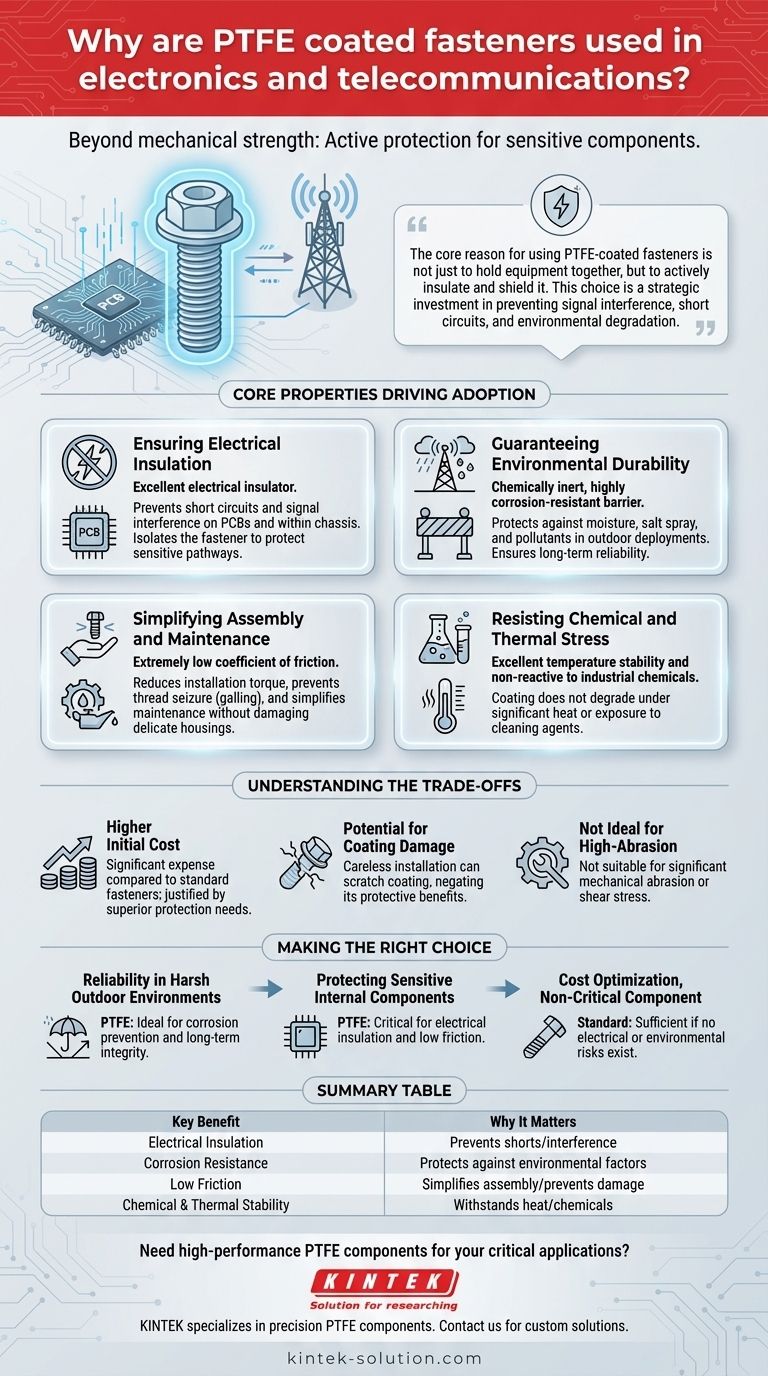

In the world of electronics and telecommunications, fastener selection goes far beyond simple mechanical strength. PTFE-coated fasteners are specifically chosen for their unique combination of properties that actively protect sensitive components, ensuring both electrical integrity and long-term operational reliability in demanding environments. Their primary benefits are exceptional electrical insulation and robust resistance to environmental corrosion.

The core reason for using PTFE-coated fasteners is not just to hold equipment together, but to actively insulate and shield it. This choice is a strategic investment in preventing signal interference, short circuits, and environmental degradation over the component's entire lifecycle.

The Core Properties Driving Adoption

The decision to use a premium fastener like one coated in Polytetrafluoroethylene (PTFE) is driven by several key performance characteristics that are critical in electronic and telecommunications applications.

Ensuring Electrical Insulation

The most critical property of PTFE in this context is its nature as an excellent electrical insulator.

Standard metal fasteners can inadvertently create conductive paths, leading to signal interference or, in the worst case, a catastrophic short circuit on a printed circuit board (PCB) or within a tightly packed chassis.

A PTFE coating effectively isolates the fastener, ensuring it does not interfere with the sensitive electronic pathways surrounding it.

Guaranteeing Environmental Durability

Telecommunications equipment is often deployed outdoors on towers or in enclosures where it is exposed to moisture, salt spray, and industrial pollutants.

PTFE provides a chemically inert and highly corrosion-resistant barrier, protecting the underlying metal fastener from rust and degradation that could compromise the structural integrity and electrical grounding of the assembly.

This ensures the long-term reliability of critical infrastructure, from cellular antennas to remote monitoring stations.

Simplifying Assembly and Maintenance

PTFE is well-known for its extremely low coefficient of friction, making it exceptionally slick.

This property significantly reduces the torque required for installation, which is vital when working with delicate plastic housings or sensitive components that could crack under high pressure.

It also prevents galling (thread seizure), making disassembly for maintenance or upgrades much smoother and reducing the risk of damaging the equipment.

Resisting Chemical and Thermal Stress

Electronic components can generate significant heat, and manufacturing processes often involve cleaning agents or solvents.

PTFE offers excellent temperature stability and is non-reactive to nearly all industrial chemicals. This ensures the fastener's protective coating will not degrade due to heat cycling or exposure to cleaning fluids.

Understanding the Trade-offs

While highly effective, PTFE-coated fasteners are not a universal solution. Acknowledging their limitations is key to making an informed engineering decision.

Higher Initial Cost

The primary drawback is cost. The coating process adds a significant expense compared to standard zinc-plated or stainless steel fasteners.

This higher cost must be justified by the need for superior protection against specific electrical or environmental risks.

Potential for Coating Damage

The protective benefit of the PTFE coating exists only as long as the coating is intact.

Careless installation with improper tools can scratch or chip the coating, creating a weak point for corrosion or electrical conduction to occur. This negates the very reason for its selection.

Not Ideal for High-Abrasion Applications

While durable, PTFE is a relatively soft material. These fasteners are not suitable for applications involving significant mechanical abrasion or shear stress that could wear away the coating over time.

Making the Right Choice for Your Goal

To apply this knowledge effectively, align your fastener choice with the primary objective of your design.

- If your primary focus is reliability in harsh outdoor environments: PTFE is an ideal choice to prevent corrosion and ensure the long-term structural and electrical integrity of exposed equipment.

- If your primary focus is protecting sensitive internal components: The electrical insulation and low-friction properties of PTFE are critical for preventing short circuits and avoiding damage during the assembly of delicate electronics.

- If your primary focus is cost optimization on a non-critical component: A standard, uncoated fastener may be sufficient, provided there is no risk of electrical interference or significant environmental exposure.

Ultimately, choosing a PTFE-coated fastener is a deliberate decision to enhance the long-term reliability and safety of your electronic or telecommunications system.

Summary Table:

| Key Benefit | Why It Matters for Electronics & Telecom |

|---|---|

| Electrical Insulation | Prevents short circuits and signal interference on PCBs and in chassis. |

| Corrosion Resistance | Protects against moisture, salt spray, and pollutants for long-term outdoor reliability. |

| Low Friction | Simplifies assembly, reduces installation torque, and prevents damage to delicate components. |

| Chemical & Thermal Stability | Withstands heat from components and exposure to cleaning agents without degrading. |

Need high-performance PTFE components for your critical applications?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom fasteners, seals, liners, and labware. Our expertise ensures your electronics, medical devices, laboratory equipment, and industrial systems benefit from superior insulation, durability, and chemical resistance.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision to meet your exact specifications.

Contact KINTEK today to discuss how our PTFE solutions can enhance the reliability and performance of your products.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- In what medical applications are PTFE Liners commonly used? Enhancing Device Performance & Patient Safety

- What are the main challenges in machining Teflon (PTFE)? Overcome Softness, Heat, and Slipperiness

- Why are custom Teflon rotary shaft seals preferred for demanding applications? Achieve Superior Reliability in Extreme Conditions

- What is the expected service life of expanded PTFE gaskets? Maximize Sealing Longevity in Harsh Environments

- What cost benefits do PTFE oil seals offer? Slash Your Total Cost of Ownership

- What are the benefits of PTFE bushes being self-lubricating? Achieve Maintenance-Free, High-Efficiency Motion

- What are the key considerations when machining PTFE? Master the Art of Precision Machining

- What are the different types of PTFE gaskets? A Guide to Choosing the Right Seal