In short, PTFE bellows are uniquely suitable for electroplating because their material properties align perfectly with the harsh demands of the process. PTFE offers a rare combination of near-total chemical inertness, high-temperature stability, and excellent electrical insulation, making it one of the few materials that can survive and perform reliably in a corrosive, electrically charged, and thermally dynamic plating environment.

The core reason for using PTFE in electroplating is not a single feature, but its unique synergy of properties. It simultaneously resists chemical attack, withstands process temperatures, and prevents electrical interference, all while providing mechanical flexibility.

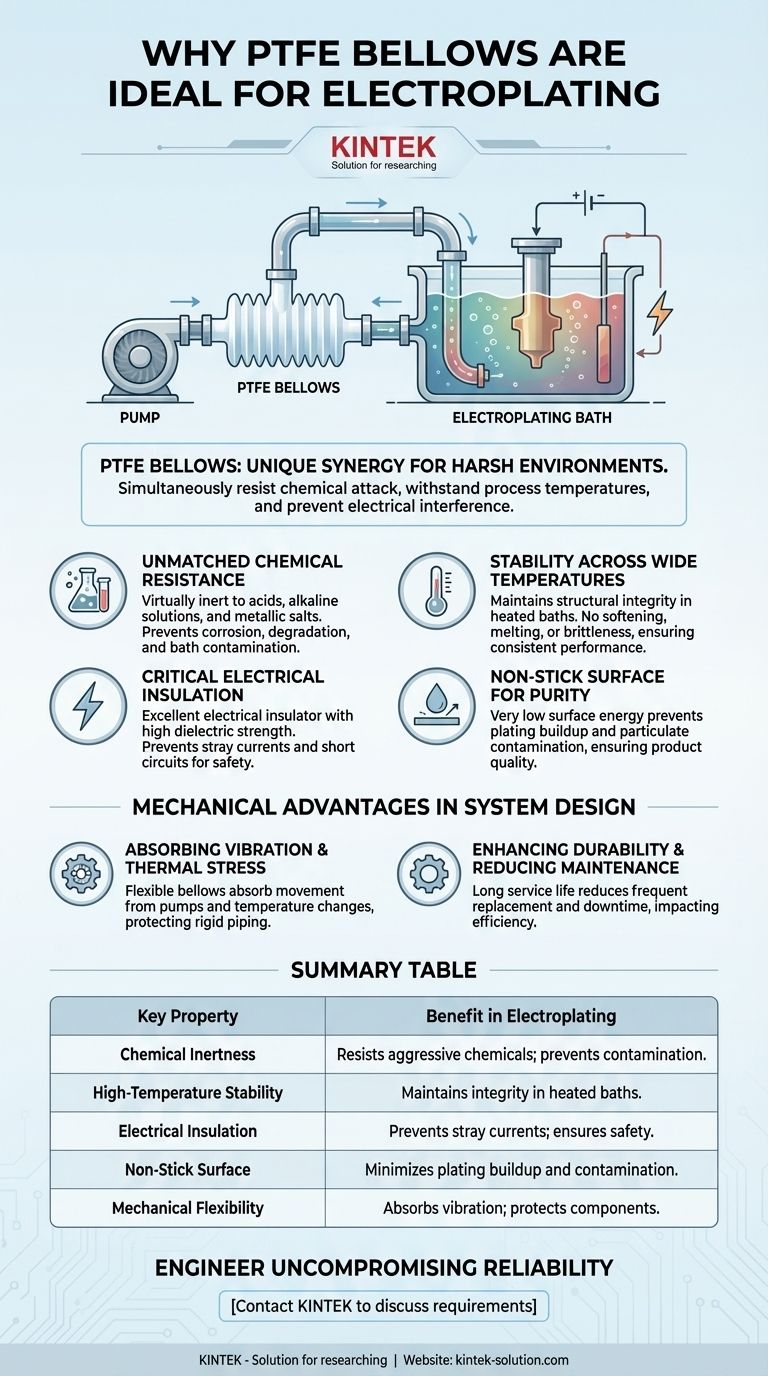

The Core Properties That Matter in Electroplating

To understand why PTFE is a superior choice, we must first break down the specific challenges of the electroplating process and how PTFE's intrinsic properties solve them.

Unmatched Chemical Resistance

Electroplating baths use highly aggressive chemicals, including strong acids, alkaline solutions, and various metallic salts.

PTFE is virtually inert to this entire spectrum of chemicals. This prevents the bellows from corroding, degrading, or dissolving, which would lead to equipment failure and catastrophic leaks.

Crucially, its inertness also prevents the material from leaching impurities into the plating bath, ensuring the purity and quality of the final plated product.

Stability Across Wide Temperature Ranges

Many electroplating processes require the bath to be heated to specific temperatures to ensure optimal deposition quality and speed.

PTFE maintains its structural integrity and mechanical properties across a very broad temperature range. It will not soften, melt, or become brittle within the typical operating temperatures of electroplating tanks.

This thermal stability ensures consistent performance and reliability, cycle after cycle.

Critical Electrical Insulation

Electroplating is an electrochemical process that relies on the precise application of electrical current to deposit metal ions onto a substrate.

PTFE is an excellent electrical insulator with high dielectric strength. Using PTFE bellows in piping and fluid transfer systems prevents the formation of stray electrical currents or short circuits through the equipment.

This ensures the electrical current is directed only where it is intended, leading to better process control and safety.

Non-Stick Surface for Purity

The surface of PTFE is non-stick, a property technically known as having very low surface energy.

This means that plating deposits are highly unlikely to adhere to the surface of the bellows. This prevents the buildup of plated material that could later flake off and contaminate the bath as particulate, which can cause defects in the final product.

Mechanical Advantages in System Design

Beyond its material properties, the bellows form factor provides distinct mechanical benefits that protect the entire electroplating system.

Absorbing Vibration and Thermal Stress

Electroplating lines often include pumps, heaters, and long runs of piping, which introduce vibration and thermal expansion or contraction.

The flexible, accordion-like shape of a bellow allows it to absorb this movement and mechanical stress. This isolates sensitive components from vibration and prevents cracks or failures in rigid piping systems.

Enhancing Durability and Reducing Maintenance

The combination of PTFE's corrosion-free nature and the bellows' ability to handle stress results in a component with an exceptionally long service life.

This durability drastically reduces the need for frequent replacement and minimizes costly downtime for maintenance, directly impacting operational efficiency.

Understanding the Trade-offs

While highly effective, it's important to recognize the specific context where PTFE excels and its potential limitations.

Considerations for Mechanical Strength

PTFE is a fluoropolymer, not a metal. While exceptionally tough and flexible, it does not possess the high tensile strength or rigidity of steel or other alloys.

In applications involving very high internal pressure or significant external physical impact, reinforced or alternative designs may be necessary.

The Initial Cost Factor

PTFE is a premium, high-performance material. The upfront cost for PTFE bellows will typically be higher than for components made from less capable elastomers or standard plastics.

However, this initial investment is almost always offset by significantly lower maintenance costs, reduced downtime, and the prevention of process contamination over the component's lifespan.

Making the Right Choice for Your Process

Selecting PTFE bellows is a strategic decision based on prioritizing reliability and process integrity in a demanding environment.

- If your primary focus is process purity and preventing contamination: PTFE is the ideal choice due to its chemical inertness and non-stick surface.

- If your primary focus is equipment longevity and reducing downtime: PTFE's unparalleled resistance to chemical and thermal degradation ensures a long, low-maintenance service life.

- If your primary focus is electrical safety and process control: The outstanding dielectric properties of PTFE provide essential insulation for maintaining a stable electrochemical process.

Ultimately, PTFE bellows provide a robust and reliable solution engineered to master the hostile conditions of modern electroplating.

Summary Table:

| Key Property | Benefit in Electroplating |

|---|---|

| Chemical Inertness | Resists aggressive acids, alkalis, and salts; prevents contamination and corrosion. |

| High-Temperature Stability | Maintains integrity in heated baths; ensures consistent performance. |

| Electrical Insulation | Prevents stray currents and short circuits for better process control and safety. |

| Non-Stick Surface | Minimizes plating buildup and particulate contamination. |

| Mechanical Flexibility | Absorbs vibration and thermal expansion, protecting system components. |

Engineer Uncompromising Reliability into Your Electroplating Line

When process purity, equipment longevity, and electrical safety are non-negotiable, the right component makes all the difference. KINTEK specializes in manufacturing precision PTFE components, including custom bellows designed to thrive in the most demanding environments.

We partner with semiconductor, medical, and industrial leaders to deliver solutions that reduce downtime and prevent contamination. From initial prototypes to high-volume production, our expertise ensures a perfect fit for your application.

Contact KINTEK today to discuss your specific requirements and discover how our PTFE bellows can enhance your process reliability and efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability