At its core, the suitability of Polytetrafluoroethylene (PTFE) bellows for corrosive environments stems from the material's fundamental chemical structure. PTFE is almost universally inert, meaning it does not react with the vast majority of industrial chemicals, acids, and solvents. This exceptional resistance ensures the bellows maintain their structural integrity and operational performance without degrading, even when exposed to the most aggressive substances.

The decision to use PTFE bellows is about more than just surviving corrosion. It is an investment in total system reliability, where chemical inertness combines with thermal stability and physical flexibility to solve multiple engineering challenges at once.

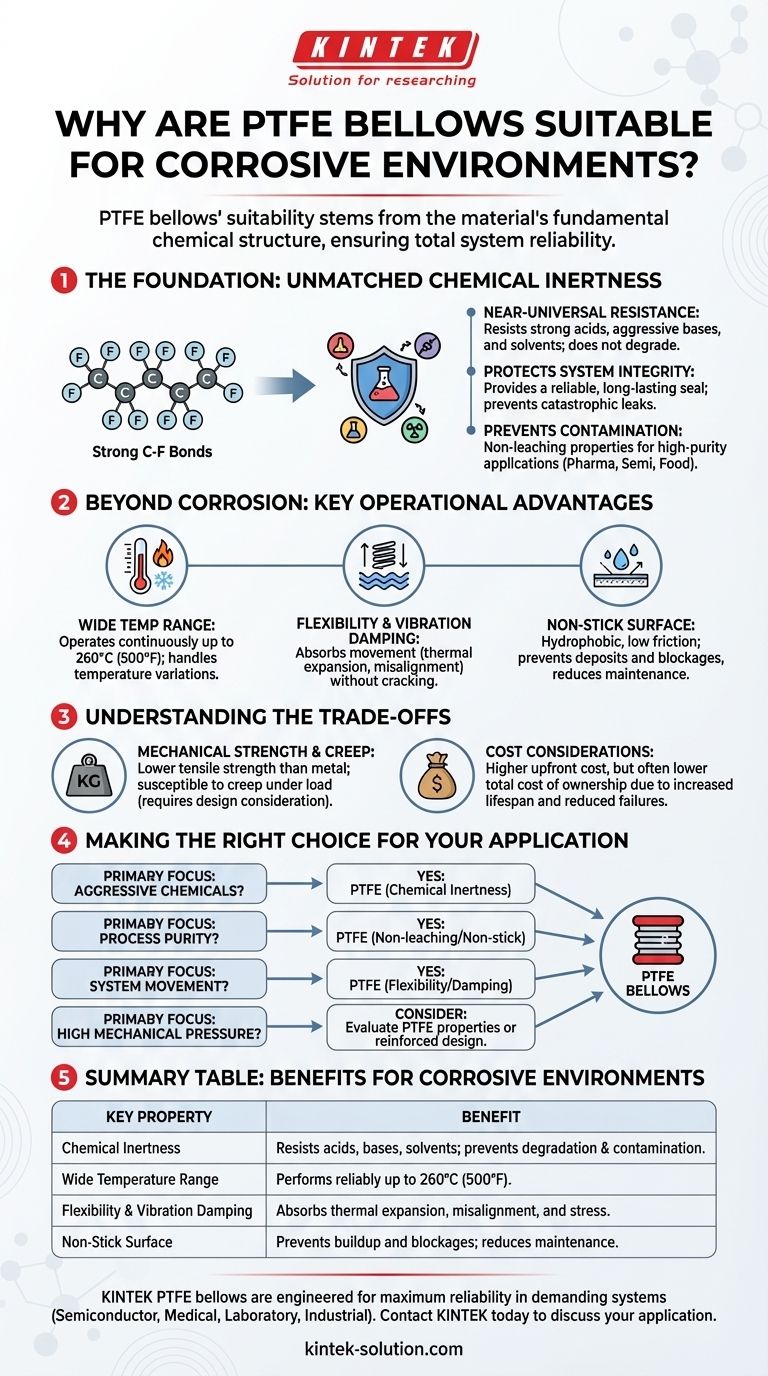

The Foundation: Unmatched Chemical Inertness

The primary reason engineers specify PTFE for demanding applications is its near-absolute chemical resistance. This property is not an additive or a coating; it is an intrinsic characteristic of the material itself.

A Near-Universal Resistance

PTFE is renowned for its stability when exposed to a vast spectrum of substances. It effectively resists strong acids, aggressive bases, solvents, and other reactive chemicals that would quickly degrade metals, elastomers, and other plastics.

This inertness is due to the strong carbon-fluorine bonds that make up the polymer's molecular backbone, which are extremely difficult for other chemicals to break.

Protecting System Integrity

In a pipeline or processing system, a failed bellows can lead to catastrophic leaks, safety hazards, and costly downtime. Because PTFE does not corrode or degrade, it provides a reliable and long-lasting seal.

This ensures the containment of aggressive media, protecting both the surrounding equipment and personnel.

Preventing Process Contamination

Because PTFE does not react with the fluid it contains, it does not leach impurities into the process stream. This is a critical advantage in high-purity applications.

Industries like pharmaceuticals, semiconductors, and food processing rely on PTFE to maintain the absolute purity of their products.

Beyond Corrosion: Key Operational Advantages

While chemical resistance is the headline feature, other properties of PTFE make it uniquely suited for the dynamic conditions where bellows are used.

Wide Operating Temperature Range

PTFE bellows perform reliably across a broad temperature spectrum, typically withstanding continuous service temperatures up to 260°C (500°F).

This makes them ideal for chemical processes that involve significant temperature variations, where other materials might become brittle or lose their shape.

Inherent Flexibility and Vibration Damping

Bellows are designed to absorb movement, including thermal expansion, pipe misalignment, and mechanical vibration.

PTFE's inherent flexibility allows it to perform these functions without cracking or failing. It effectively isolates vibration, reducing stress on the entire piping system.

A Natural Non-Stick Surface

PTFE has an extremely low coefficient of friction and is hydrophobic, creating a non-stick surface.

This property prevents deposits, scale, or other media from building up inside the bellows, ensuring efficient and consistent fluid flow. It also dramatically reduces the need for cleaning and maintenance, preventing blockages.

Understanding the Trade-offs

No material is perfect for every scenario. Understanding the limitations of PTFE is crucial for proper application and design.

Mechanical Strength and Creep

Compared to metal bellows, PTFE has lower tensile strength and is more susceptible to creep—a slow, permanent deformation under sustained load, especially at elevated temperatures.

This must be accounted for during system design, particularly in high-pressure applications or where the bellows are under significant mechanical stress.

Cost Considerations

Machined PTFE components can have a higher upfront cost than some alternatives.

However, this is often offset by a lower total cost of ownership due to increased lifespan, reduced maintenance, and the prevention of costly failures in corrosive environments.

Making the Right Choice for Your Application

Selecting the right material requires aligning its properties with your primary engineering goal.

- If your primary focus is handling highly aggressive chemicals: PTFE is the default choice due to its near-universal chemical inertness, which guarantees component longevity.

- If your primary focus is process purity (pharma, semiconductors): PTFE's non-leaching and non-stick characteristics are essential for preventing contamination and ensuring product quality.

- If your primary focus is managing system movement: The combination of flexibility, vibration damping, and a wide operating temperature range makes PTFE a reliable solution for thermal expansion and misalignment.

- If your primary focus is high mechanical pressure: Carefully evaluate the system's operating pressure and temperature to ensure PTFE's mechanical properties are sufficient, or consider a reinforced design.

Ultimately, choosing PTFE bellows is a strategic decision to ensure long-term safety, purity, and operational reliability in your most demanding systems.

Summary Table:

| Key Property | Benefit for Corrosive Environments |

|---|---|

| Chemical Inertness | Resists strong acids, bases, and solvents; prevents degradation and contamination. |

| Wide Temperature Range | Performs reliably from cryogenic temperatures up to 260°C (500°F). |

| Flexibility & Vibration Damping | Absorbs thermal expansion, misalignment, and mechanical stress. |

| Non-Stick Surface | Prevents buildup and blockages, reducing maintenance needs. |

Need a reliable sealing solution for aggressive chemicals?

PTFE bellows from KINTEK are engineered for maximum reliability in your most demanding systems. We specialize in manufacturing high-precision PTFE components—including custom bellows, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

Our expertise ensures your components are designed to handle extreme conditions, protecting your equipment, ensuring process purity, and preventing costly downtime.

Contact KINTEK today to discuss your application requirements and receive a custom solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- In which industries are PTFE compensators commonly used? Essential for Corrosive & High-Purity Systems

- What are the primary uses of PTFE polymer-plastic ball bearings? Ideal for Harsh & Sensitive Environments

- What makes PTFE chemically resistant? The Power of Fluorine's Protective Shield

- What are the benefits of using PTFE for seals and gaskets? Unlock Superior Chemical & Thermal Resistance

- How does the shrinkage performance of PTFE gaskets affect their functionality? Ensure a Perfect, Leak-Free Seal

- What are the standard sheet sizes for PTFE? Optimize Your Material Selection

- How can thermal expansion be managed during PTFE machining? Master Precision with a Multi-Faceted Strategy

- What industries commonly use PTFE lined butterfly valves? Essential for Corrosive & High-Purity Applications