In the medical field, PTFE bellows are vital components chosen for their unique combination of material purity and mechanical resilience. Their importance stems directly from three core properties: they are highly biocompatible, chemically inert, and can be reliably sterilized, making them essential for ensuring patient safety and device reliability in applications like ventilators and anesthesia machines.

The decision to use PTFE bellows in a medical device is not just a material choice; it's a risk management strategy. In environments where material failure or contamination can have severe consequences, PTFE provides a level of chemical stability and purity that few other flexible materials can match.

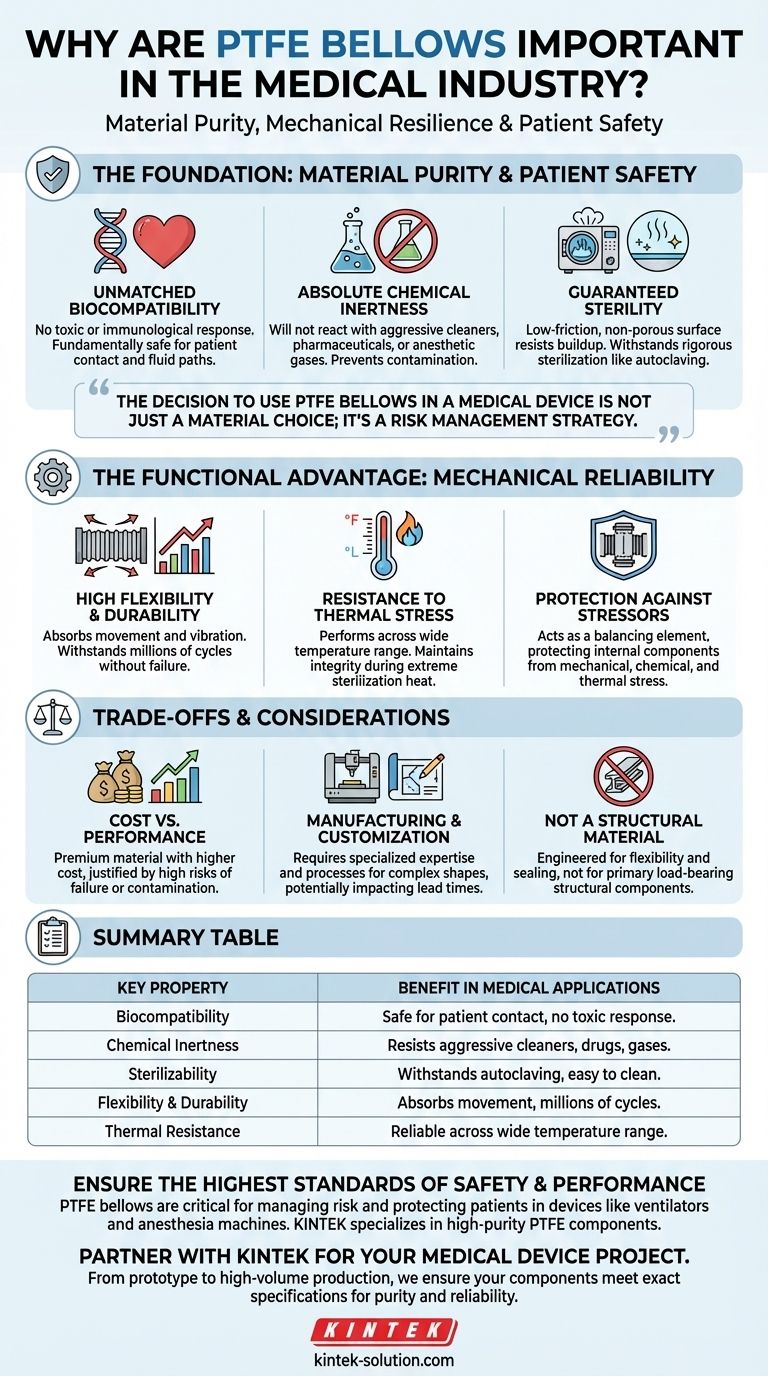

The Foundation: Material Purity and Patient Safety

The suitability of any material for medical use begins with its interaction with the human body and the sensitive substances it will encounter. PTFE excels in these foundational requirements.

Unmatched Biocompatibility

PTFE is exceptionally biocompatible, meaning it does not produce a toxic or immunological response when exposed to the body or bodily fluids. This makes it a fundamentally safe choice for components that are part of a patient's breathing circuit or fluid path.

Absolute Chemical Inertness

The material is almost completely chemically inert. It will not react with or degrade from contact with the aggressive cleaning agents used in hospitals, nor will it react with the wide range of pharmaceuticals or anesthetic gases it might transport. This ensures the material itself does not become a point of failure or a source of contamination.

Guaranteed Sterility

PTFE has a low-friction, non-porous surface that resists the buildup of biological matter or deposits. This non-stick quality, combined with its ability to withstand a wide operating temperature range, makes it easy to clean and compatible with rigorous sterilization methods like autoclaving.

The Functional Advantage: Mechanical Reliability

Beyond its chemical purity, PTFE bellows provide the mechanical performance necessary for dynamic medical equipment. They act as durable, flexible connectors that protect sensitive equipment.

High Flexibility and Durability

Bellows are designed to absorb movement, misalignment, and vibration between parts. PTFE's inherent flexibility and long-term durability mean it can withstand millions of cycles in devices like ventilators without cracking or failing, ensuring consistent performance.

Resistance to Thermal Stress

Medical devices can generate heat or be subjected to extreme temperatures during sterilization. PTFE's ability to perform across a wide temperature range ensures the bellows maintain their structural integrity and sealing capability without becoming brittle or weak.

Protection Against System Stressors

Functionally, PTFE bellows serve as balancing elements. They protect internal components from mechanical, chemical, or thermal stressors, extending the life of the entire device and reducing the need for maintenance.

Understanding the Trade-offs and Considerations

While PTFE offers superior performance, it is critical to understand its specific context of use. It is not a universal solution for every application.

Cost vs. Performance

PTFE is a premium performance material, and its cost is typically higher than that of alternatives like medical-grade silicone or rubber. Its use is justified where the risks of chemical incompatibility or material degradation are unacceptably high.

Manufacturing and Customization

Machining or molding PTFE into complex bellows shapes requires specialized expertise and processes. This can impact lead times and the cost of highly customized designs compared to more common elastomers.

Not a Structural, Load-Bearing Material

PTFE bellows are engineered for flexibility, sealing, and fluid transfer. They are not intended to be primary structural or load-bearing components within a device. Their strength lies in movement and protection, not rigidity.

Making the Right Choice for Your Application

Selecting the right material requires aligning its properties with the primary goal of your device.

- If your primary focus is patient-facing contact or drug delivery: The non-negotiable biocompatibility and chemical inertness of PTFE make it the safest choice.

- If your primary focus is mechanical longevity in a dynamic device: The superior flexibility and cycle life of PTFE bellows reduce the risk of material fatigue and failure.

- If your primary focus is maintaining absolute sterility: PTFE's non-stick surface and tolerance for high-temperature sterilization provide unmatched reliability.

Ultimately, specifying PTFE bellows is a decision to prioritize safety, reliability, and long-term performance in critical medical applications.

Summary Table:

| Key Property | Benefit in Medical Applications |

|---|---|

| Biocompatibility | Safe for patient contact, no toxic or immunological response. |

| Chemical Inertness | Resists aggressive cleaners, pharmaceuticals, and anesthetic gases. |

| Sterilizability | Withstands autoclaving; non-porous, non-stick surface is easy to clean. |

| Flexibility & Durability | Absorbs movement and vibration, withstanding millions of cycles. |

| Thermal Resistance | Performs reliably across a wide temperature range, including sterilization. |

Ensure the highest standards of safety and performance for your medical device.

PTFE bellows are a critical component in managing risk and protecting patients. KINTEK specializes in the precision manufacturing of high-purity PTFE components, including custom bellows, for the medical, semiconductor, and laboratory industries.

We partner with you from prototype to high-volume production, ensuring your components meet exact specifications for material purity and mechanical reliability.

Contact KINTEK today to discuss how our PTFE expertise can enhance your next medical device project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What standards and compliance measures are followed in manufacturing Teflon parts? Ensuring Quality from ISO to Final Inspection

- What are the typical tolerances for PTFE balls? Achieve Perfect Fit and Performance

- What tools and coolants are recommended for machining Teflon (PTFE)? Achieve Clean, Precise Cuts

- What maintenance practices ensure optimal PTFE butterfly valve performance? Maximize Lifespan & Reliability

- What are the advantages of compression molding for PTFE? Unlock Superior Performance for Large, Dense Components

- Why is PTFE preferred for electric actuated butterfly valves? For Unmatched Reliability in Harsh Conditions

- How often should a PTFE coating thrust washer be replaced? Proactive Maintenance for Peak Performance

- What are the five main advantages of PTFE O-rings? Superior Sealing for Harsh Environments