At its core, PTFE bars are considered essential in modern industry because they provide an unparalleled combination of chemical inertness, thermal stability, and electrical insulation. This unique trio of properties allows them to function reliably in extreme environments where nearly all other plastics and even many metals would fail, ensuring safety, longevity, and operational efficiency.

The true value of PTFE isn't just one standout feature, but its ability to solve multiple critical challenges at once. It is the go-to material for applications demanding simultaneous resistance to harsh chemicals, high temperatures, and electrical stress.

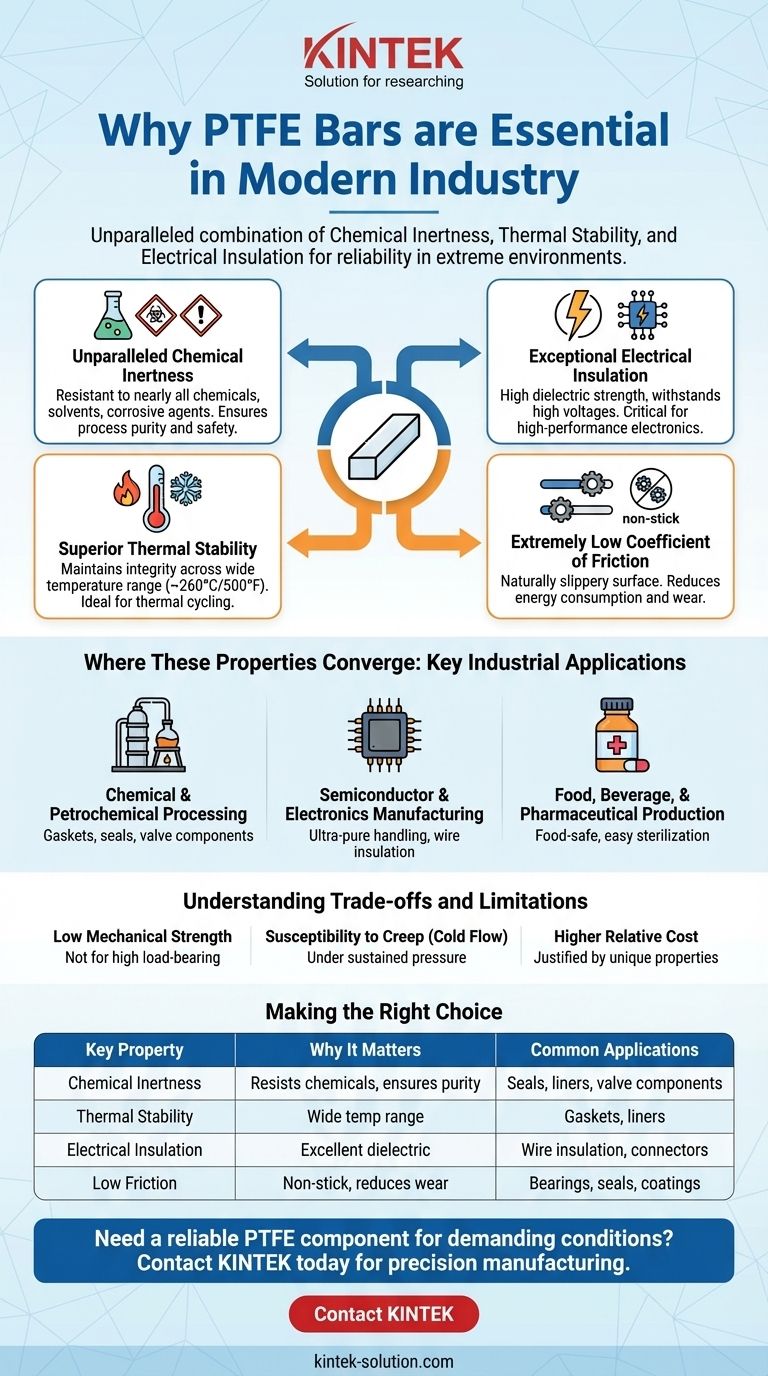

The Core Properties That Define PTFE's Value

To understand why PTFE (Polytetrafluoroethylene) is so indispensable, you must first understand the fundamental properties that set it apart. These are not just incremental improvements over other materials; they are often orders of magnitude better, creating unique engineering possibilities.

Unparalleled Chemical Inertness

PTFE is famously resistant to nearly all industrial chemicals, solvents, and corrosive agents. This is because the strong carbon-fluorine bonds in its molecular structure are exceptionally stable and difficult to break.

This inertness makes it the premier choice for components that will be in direct contact with aggressive substances, preventing material degradation, ensuring process purity, and enhancing plant safety.

Superior Thermal Stability

PTFE maintains its integrity across a remarkably wide operating temperature range. It remains functional and stable at high temperatures where other polymers would melt or degrade.

This makes it ideal for high-temperature seals, gaskets, and liners in chemical reactors, engines, and industrial processing equipment that experience significant thermal cycling.

Exceptional Electrical Insulation

PTFE is one of the best electrical insulators known. It possesses a very high dielectric strength and volume resistivity, meaning it can withstand high voltages without breaking down and does not conduct electricity.

Its performance remains consistent across a wide spectrum of frequencies and temperatures, making it a critical material for high-performance wire insulation, connectors, and components in the semiconductor and aerospace industries.

Extremely Low Coefficient of Friction

Often recognized by its commercial name, Teflon™, PTFE has one of the lowest coefficients of friction of any solid material. It provides a naturally "non-stick" and slippery surface.

This property is vital for creating high-performance, low-wear seals, bearings, and coatings on moving parts, reducing energy consumption and extending the service life of machinery.

Where These Properties Converge: Key Industrial Applications

The combination of these elite properties makes PTFE bars the source material for critical components across several high-stakes industries.

Chemical and Petrochemical Processing

In this sector, the primary challenges are corrosion and high temperatures. PTFE is machined into gaskets, seals, and valve components that prevent leaks of hazardous materials. It's also used to line pipes and vessels, creating a non-reactive barrier that protects the structural metal from corrosion.

Semiconductor and Electronics Manufacturing

Purity and electrical performance are paramount here. PTFE's chemical inertness ensures it doesn't contaminate the ultra-pure chemicals used in semiconductor fabrication. Its outstanding dielectric properties are essential for insulating micro-wiring and high-frequency cables, preventing signal loss or short circuits.

Food, Beverage, and Pharmaceutical Production

Food-safe grades of PTFE are used extensively due to their non-stick nature, high-temperature resistance, and chemical stability. This allows for easy sterilization and cleaning, prevents cross-contamination, and ensures the material won't react with food or pharmaceutical products.

Understanding the Trade-offs and Limitations

No material is perfect, and being a trusted advisor means acknowledging a material's limitations. Understanding PTFE's trade-offs is key to using it correctly.

Low Mechanical Strength

PTFE is a relatively soft material. Compared to engineering plastics like PEEK or metals, it has low tensile strength and is not suitable for applications requiring high structural or load-bearing capacity on its own.

Susceptibility to Creep (Cold Flow)

Under sustained pressure, especially at elevated temperatures, PTFE can slowly deform or "creep." This must be accounted for in the design of critical seals and gaskets to ensure long-term performance without failure.

Higher Relative Cost

As a high-performance fluoropolymer, PTFE is more expensive than common commodity plastics like polypropylene or polyethylene. Its use is justified when its unique properties are a strict requirement for performance or safety, not as a general-purpose material.

Making the Right Choice for Your Application

Selecting the correct material requires matching the primary challenge of your application to the core strengths of the material.

- If your primary focus is extreme chemical resistance or process purity: PTFE is the definitive choice for seals, liners, and fluid-handling components in aggressive environments.

- If your primary focus is high-performance electrical insulation: PTFE is a leading candidate for critical applications in high-frequency, high-temperature, or high-voltage electronics.

- If your primary focus is low friction and smooth operation: PTFE is an excellent option for non-stick surfaces, low-drag seals, and maintenance-free bearings.

- If your primary focus is structural strength under high mechanical load: You should evaluate other engineering plastics or metals, or consider a "filled" grade of PTFE which adds materials like glass or carbon to improve mechanical properties.

Ultimately, PTFE's essential role comes from its ability to provide reliability where other materials simply cannot survive.

Summary Table:

| Key Property | Why It Matters | Common Applications |

|---|---|---|

| Chemical Inertness | Resists nearly all industrial chemicals, ensuring process purity and safety. | Seals, liners, and valve components in chemical processing. |

| Thermal Stability | Maintains integrity from cryogenic to high temperatures (~260°C/500°F). | High-temperature gaskets and liners in reactors and engines. |

| Electrical Insulation | Excellent dielectric strength, ideal for high-frequency/high-voltage use. | Wire insulation and connectors in semiconductor and aerospace. |

| Low Friction | Naturally non-stick, reducing wear and energy consumption in machinery. | Bearings, seals, and non-stick coatings. |

Need a reliable PTFE component that can withstand your most demanding conditions?

At KINTEK, we specialize in precision manufacturing of high-performance PTFE components—from custom seals and liners to complex labware. Whether you need a prototype or a high-volume order for the semiconductor, medical, laboratory, or industrial sectors, our expertise ensures you get a part that delivers unmatched chemical resistance, thermal stability, and electrical insulation.

Contact KINTEK today to discuss your specific requirements and get a quote for a solution built to last.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications