In High-Performance Liquid Chromatography (HPLC), septa are constructed from Polytetrafluoroethylene (PTFE) and silicone rubber because these two materials provide a complementary set of properties essential for analytical integrity. PTFE offers supreme chemical inertness to protect the sample from contamination, while silicone provides the mechanical flexibility and re-sealing capability required to maintain a closed, pressurized system after needle piercing.

The choice is not simply PTFE versus silicone, but rather how to best combine them. A PTFE/Silicone laminated septum leverages PTFE's chemical resistance as a protective barrier and silicone's elasticity for a reliable, repeatable seal, offering the most robust solution for modern analytical demands.

The Septum's Critical Role in HPLC

An HPLC vial septum acts as a protective barrier. Its primary job is to seal the vial, preventing solvent evaporation and sample contamination, while still allowing an autosampler needle to pierce it for injection without compromising the system.

The Need for a Perfect Mechanical Seal

A key function of the septum is to be pierced cleanly by the HPLC needle and then reseal completely upon withdrawal. This is a mechanical challenge.

Silicone rubber is the ideal material for this task. Its soft, elastic nature allows the needle to pass through with minimal force, reducing wear on the needle tip. Most importantly, its "memory" allows it to close the puncture hole, preventing solvent evaporation and maintaining the vial's internal environment.

The Need for Absolute Chemical Inertness

The mobile phases and sample solvents used in HPLC can be highly aggressive, including strong acids, bases, and a wide array of organic solvents.

The septum must not react with or degrade in the presence of these chemicals. If it does, material can leach into the sample, introducing contaminants that appear as "ghost peaks" in the chromatogram and invalidate the results. This is where PTFE's properties become essential.

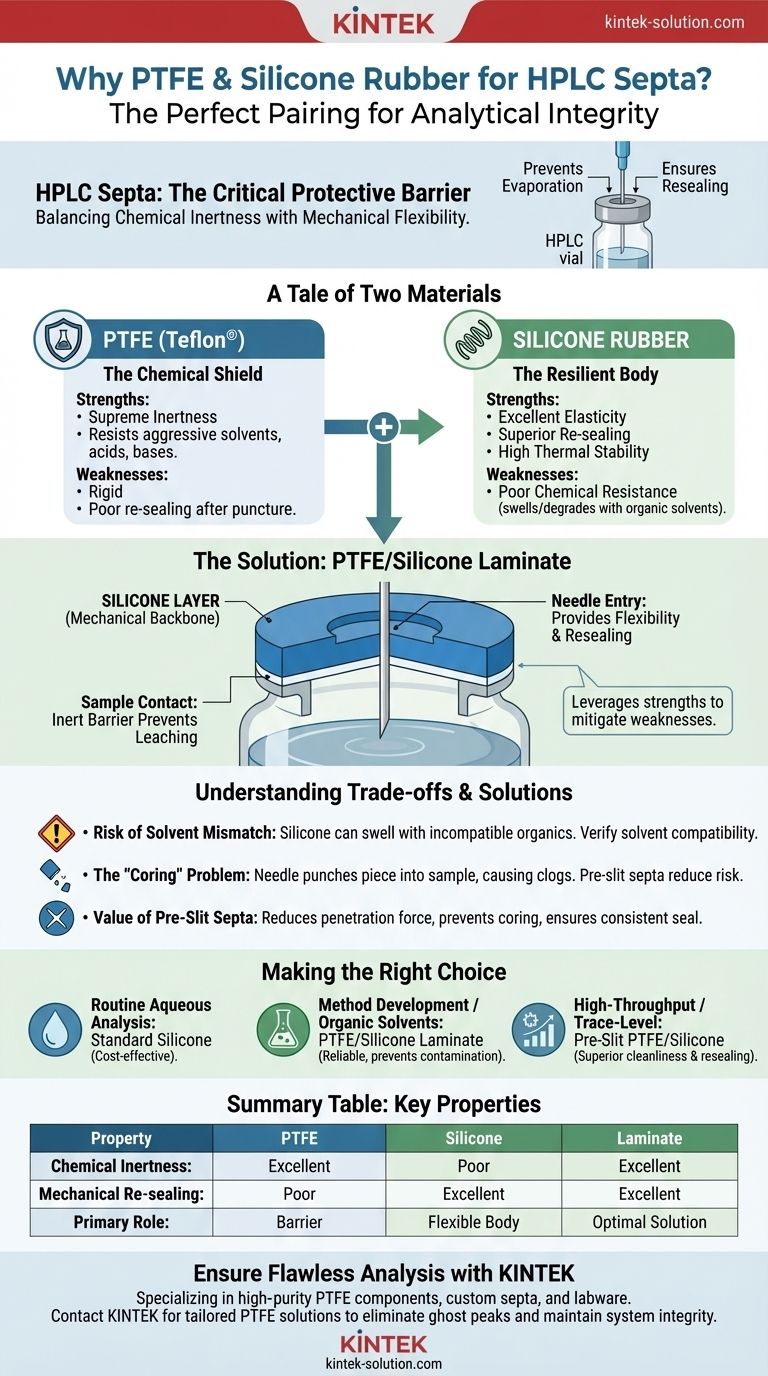

A Tale of Two Materials

Neither material is perfect on its own. Their true power is realized when their strengths are combined to mitigate their individual weaknesses.

The Chemical Shield: The Power of PTFE

PTFE, known by the trade name Teflon®, is one of the most non-reactive materials known. It is virtually immune to attack from the vast majority of chemicals used in a chromatography lab.

However, pure PTFE is a relatively hard and rigid material. It does not re-seal well after being punctured, making it unsuitable as a standalone septum material for repeated injections.

The Resilient Body: The Advantage of Silicone

Silicone rubber provides excellent elasticity and thermal stability, making it the perfect mechanical backbone for a septum. It can be punctured hundreds of times and still provide a reliable seal.

The primary weakness of silicone is its limited chemical resistance. When exposed to certain organic solvents, such as hexane, toluene, or chlorinated solvents, it can swell or degrade, compromising the seal and potentially leaching impurities.

The Best of Both Worlds: The PTFE/Silicone Laminate

The most common and effective solution is the laminated septum. This design features a thin, 0.005" to 0.010" layer of PTFE bonded to a much thicker layer of silicone.

In the vial, the PTFE side faces the sample and solvent, acting as a completely inert chemical barrier. The silicone layer, protected from chemical contact, provides the superior flexibility and re-sealing capability. This combination delivers the best of both properties without compromise.

Understanding the Trade-offs and Pitfalls

Even with the ideal materials, improper selection or use can lead to problems. Understanding these limitations is key to ensuring reliable analysis.

The Risk of Solvent Mismatch

Using a pure silicone septum with incompatible organic solvents is a common mistake. The resulting swelling can cause the septum to unseat from the cap, leading to sample evaporation and failed sequences. Always verify solvent compatibility.

The "Coring" Problem

"Coring" occurs when the needle punches out a tiny piece of the septum material, which then falls into the sample. This particle can be drawn into the needle and clog the narrow tubing of the HPLC system, leading to significant downtime and repairs.

The Value of Pre-Slit Septa

To mitigate coring and reduce the force needed for penetration, many modern septa are pre-slit. A small cross, Y-shape, or single slit is cut into the center of the septum. This provides a path of least resistance for the needle, preventing coring, reducing needle wear, and ensuring a more consistent seal, especially in high-throughput applications.

Making the Right Choice for Your Analysis

Your choice of septum should be a deliberate decision based on your specific analytical method and goals.

- If your primary focus is routine analysis with aqueous buffers: A standard silicone septum may be a cost-effective and sufficient choice, as there is little risk of chemical incompatibility.

- If your primary focus is method development or analysis with organic solvents: A PTFE/Silicone laminated septum is the safest and most reliable option to prevent contamination and ensure data integrity.

- If your primary focus is high-throughput screening or trace-level analysis: A pre-slit PTFE/Silicone septum is the superior choice, as it minimizes the risk of coring and ensures maximum cleanliness and resealing performance.

Choosing the correct septum is a simple but critical step in guaranteeing the quality and reliability of your chromatographic data.

Summary Table:

| Property | PTFE (Teflon®) | Silicone Rubber | Combined Laminate |

|---|---|---|---|

| Chemical Inertness | Excellent (resists acids, bases, solvents) | Poor (can swell/degrade) | Excellent (PTFE faces sample) |

| Mechanical Re-sealing | Poor (rigid, doesn't re-seal well) | Excellent (elastic, re-seals after puncture) | Excellent (silicone provides seal) |

| Primary Role | Chemical barrier to prevent leaching | Flexible body for needle penetration and re-sealing | Optimal solution for both needs |

| Best For | Protecting against aggressive solvents | Routine analysis with aqueous buffers | Method development, organic solvents, high-throughput |

Ensure Flawless HPLC Analysis with Precision PTFE Components from KINTEK

Choosing the right septum is critical for protecting your samples and equipment. At KINTEK, we specialize in manufacturing high-purity PTFE components—including custom septa, seals, liners, and labware—specifically designed for demanding applications in semiconductor, medical, laboratory, and industrial settings.

Our expertise in precision production and custom fabrication means we can deliver solutions that perfectly match your HPLC requirements, from prototype development to high-volume orders. We understand that even minor contaminants or seal failures can compromise your results, which is why we prioritize material integrity and exacting specifications in every component we produce.

Let us help you eliminate ghost peaks, prevent coring, and maintain system integrity. Contact KINTEK today to discuss your specific needs and discover how our tailored PTFE solutions can enhance the reliability and accuracy of your analytical processes.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Three Neck Flasks for Advanced Chemical Applications

People Also Ask

- What are the key properties of PTFE syringe filters? Unlock Unmatched Chemical Resistance and Versatility

- How does the manufacturer's reputation and quality assurance impact the choice of a PTFE-coated septum? Ensure Data Integrity

- What are the limitations of PTFE/silicone septa regarding temperature? Key Factors for Analytical Integrity

- How do PTFE silicone septas enhance efficiency in pharmaceutical analytical processes? Boost Lab Throughput & Data Integrity

- What role do sealing properties play in the effectiveness of PTFE/silicone septums? Ensure Sample Integrity and Data Accuracy

- Why is PTFE suitable for medical laboratories? Ensure Unmatched Safety and Reliability

- What are the main advantages of PTFE as a material for laboratory bottles? Superior Chemical & Thermal Resistance

- What are the advantages of PTFE shovels over metal shovels? Precision Handling for Sensitive Materials