For sealing uneven surfaces or fragile flanges, expanded PTFE (ePTFE) is the definitive choice. Unlike standard, rigid PTFE, the unique properties of ePTFE allow it to conform to surface imperfections and create a reliable seal with minimal force, preventing damage to delicate components like glass-lined steel, plastic, or ceramic flanges.

The core issue with challenging flanges is achieving a tight seal without applying excessive pressure. Expanded PTFE's soft, compressible structure solves this directly, offering high performance where rigid gaskets would fail or cause damage.

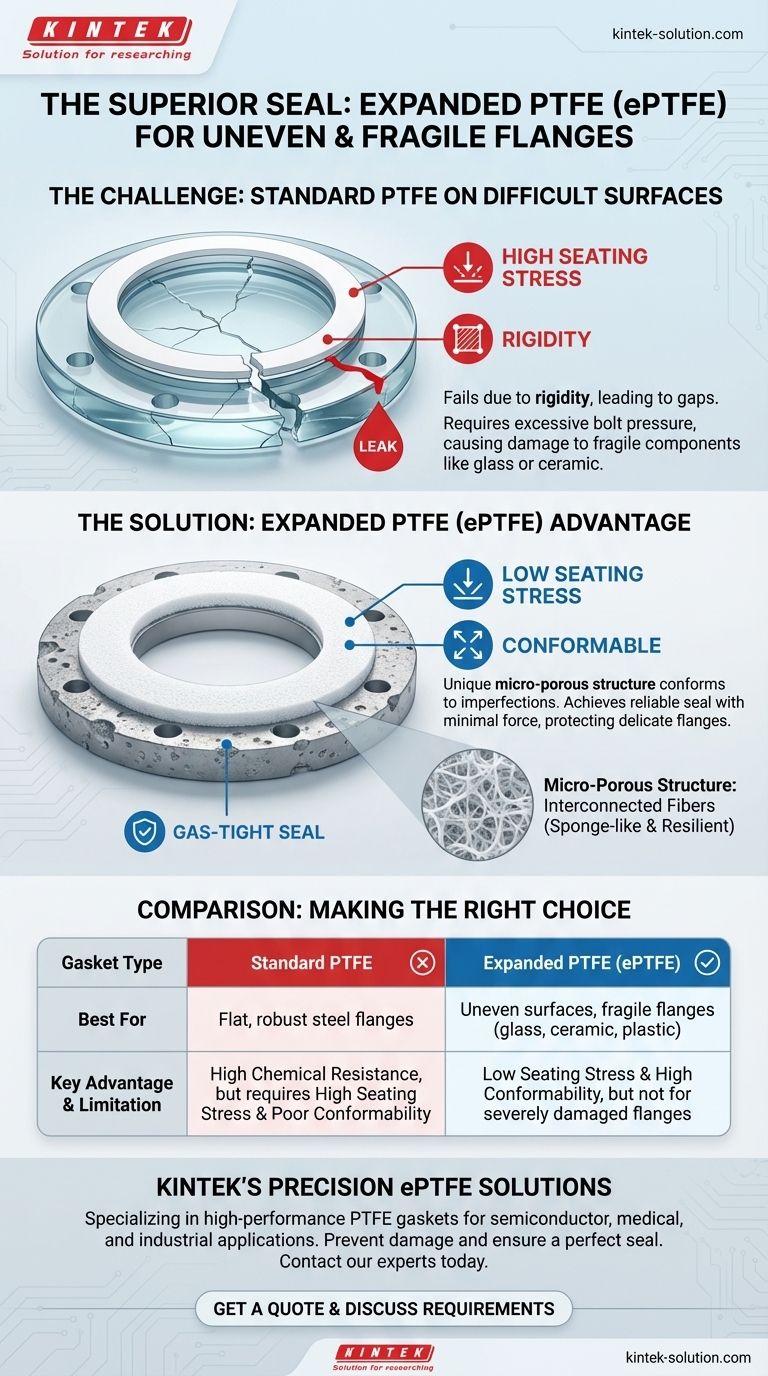

Why Standard PTFE Fails on Difficult Surfaces

To understand why ePTFE excels, we must first recognize the limitations of conventional PTFE gaskets in these specific scenarios.

The Problem with Rigidity

Standard (virgin or filled) PTFE is a relatively hard, dense material. While excellent for its chemical inertness, it lacks the flexibility to flow into the microscopic pits, scratches, and warped areas of an uneven flange face.

This rigidity means it cannot adequately compensate for surface imperfections, often leaving small gaps that lead to leaks under pressure.

High Seating Stress Requirements

To force a rigid gasket to seal, a significant amount of bolt pressure, or seating stress, is required. This high compressive load is necessary to make the material deform even slightly to match the flange.

On fragile flanges made of materials like glass, ceramic, or plastic, this high required torque can easily cause them to crack or break long before a proper seal is achieved.

The Unique Advantage of Expanded PTFE (ePTFE)

Expanded PTFE is manufactured differently, resulting in a material with a unique micro-porous structure that is both soft and exceptionally strong.

A Conformable, Micro-Porous Structure

ePTFE consists of a web of interconnected fibers. This structure makes the gasket remarkably soft and flexible, allowing it to easily compress and conform to even rough or damaged sealing surfaces.

Think of it as a highly resilient, dense sponge. It fills every void and imperfection on the flange face, creating a superior, gas-tight seal.

Low Seating Stress for a Tight Seal

Because of its softness, an ePTFE gasket requires very little bolt load to achieve an effective seal. This is the single most critical feature for protecting fragile flanges.

You can achieve a reliable, long-lasting seal without risking damage to sensitive or expensive equipment.

Resilience Under Pressure

Despite its softness, ePTFE is incredibly tough. It resists cold flow and creep, and can sustain compressive stresses up to 40,000 psi without losing its sealing integrity. This ensures the seal remains stable even in demanding industrial applications.

Understanding the Trade-offs

While ePTFE is the ideal solution for uneven and fragile flanges, a complete technical assessment requires considering all application parameters.

Verify Chemical and Thermal Compatibility

Like all gaskets, you must ensure the material is compatible with your application's specific chemicals, temperatures, and pressures. While PTFE has broad resistance, always check the manufacturer's specifications against your process conditions.

Not a Cure for Catastrophic Damage

ePTFE excels at sealing worn, pitted, or slightly warped flanges. However, it is not a substitute for proper flange maintenance. It cannot fix a flange that is severely cracked, broken, or fundamentally out of alignment.

Making the Right Choice for Your Application

Use the condition of your flange as the primary factor in your selection process.

- If your primary focus is sealing fragile flanges (e.g., glass-lined, plastic, ceramic): Expanded PTFE is the default choice to prevent catastrophic failure from excessive bolt torque.

- If your primary focus is sealing worn, pitted, or uneven metal flanges: Expanded PTFE's superior conformability will provide a much more reliable and durable seal than standard PTFE.

- If you have perfectly flat, robust steel flanges in a standard application: You can consider standard or filled PTFE, but you must still verify it meets the chemical and temperature requirements of your system.

Choosing the right gasket is about matching the material's properties to the specific challenges of the application.

Summary Table:

| Gasket Type | Best For | Key Advantage | Key Limitation |

|---|---|---|---|

| Expanded PTFE (ePTFE) | Uneven surfaces, fragile flanges (glass, ceramic, plastic) | Low seating stress, high conformability, prevents damage | Not suitable for severely cracked or misaligned flanges |

| Standard PTFE | Flat, robust steel flanges | Excellent chemical resistance | High seating stress, poor conformability, risks flange damage |

Protect your sensitive equipment and achieve a perfect seal with KINTEK's precision ePTFE gaskets.

We specialize in manufacturing high-performance PTFE components, including custom ePTFE gaskets designed for the unique challenges of semiconductor, medical, laboratory, and industrial applications. Our expertise ensures you get a sealing solution that combines superior conformability with the chemical resistance of PTFE, preventing damage to fragile flanges and eliminating leaks.

Whether you need a prototype or high-volume production, KINTEK delivers precision and reliability. Contact our experts today to discuss your specific sealing requirements and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications