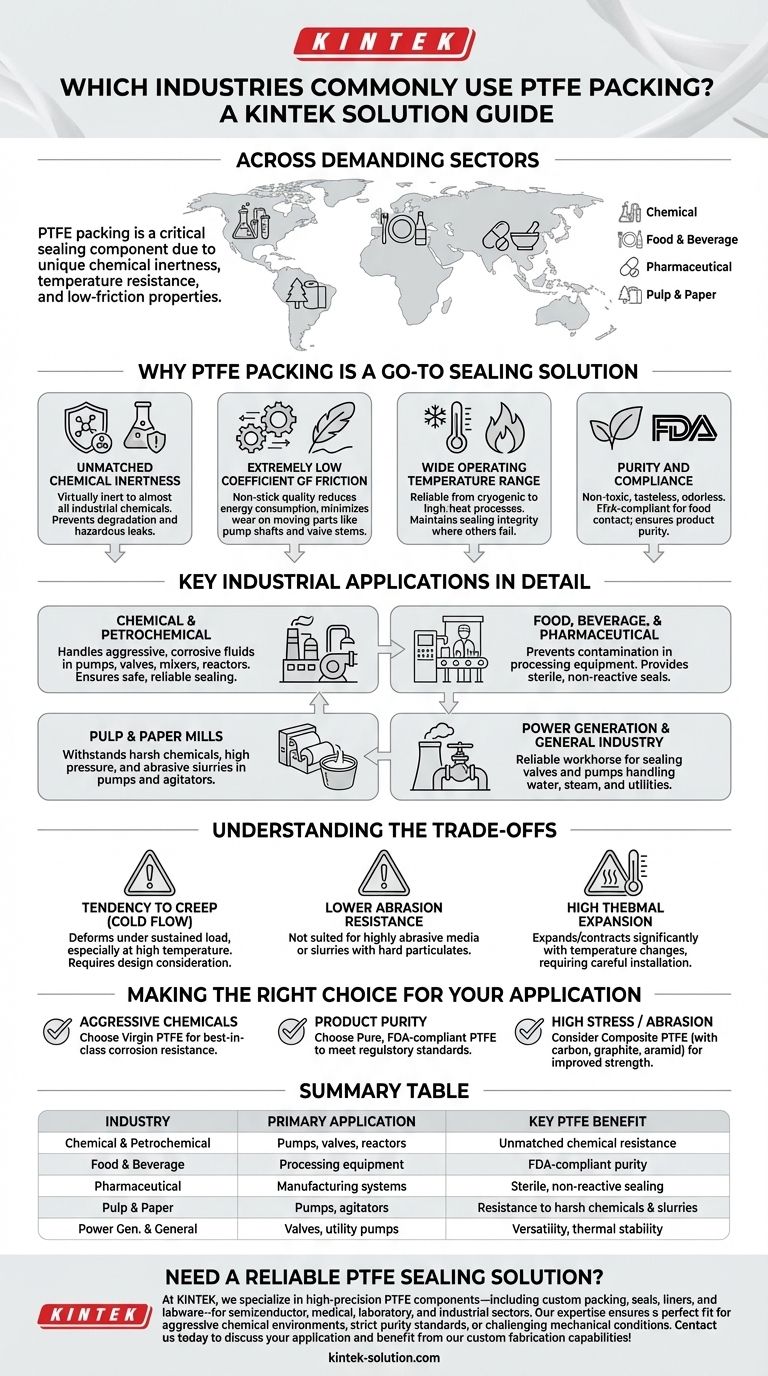

Across a wide range of demanding sectors, Polytetrafluoroethylene (PTFE) packing is a critical sealing component. It is most commonly used in the chemical processing, food and beverage, pharmaceutical, and pulp and paper industries due to its unique combination of chemical inertness, temperature resistance, and low-friction properties.

The widespread adoption of PTFE packing stems from a simple fact: it solves the problem of sealing aggressive or sensitive media where other materials would quickly fail, corrode, or cause contamination. Its value lies not in a single feature, but in its unique blend of protective properties.

Why PTFE Packing Is a Go-To Sealing Solution

The reason PTFE is so prevalent is that it possesses a set of core characteristics that make it uniquely suited for challenging industrial environments. Understanding these properties reveals why it is the default choice for many critical applications.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, including strong acids, bases, and solvents. This resistance prevents the packing from degrading and ensures the purity of the media being processed.

This makes it indispensable in applications where seal failure could lead to hazardous leaks or product contamination.

Extremely Low Coefficient of Friction

Often marketed as Teflon™, PTFE has one of the lowest coefficients of friction of any solid material. This "non-stick" quality is critical in dynamic applications like pumps and valves.

A low-friction seal reduces the energy needed to operate the equipment and minimizes wear on moving parts like pump shafts and valve stems, leading to longer service life and lower maintenance costs.

Wide Operating Temperature Range

PTFE packing performs reliably across a vast temperature spectrum, from cryogenic applications to high-heat processes. This thermal stability allows it to maintain its sealing integrity in environments where other elastomers or plastics would become brittle or melt.

Purity and Compliance

Virgin PTFE is non-toxic, tasteless, and odorless, making it compliant with strict regulatory standards like those from the FDA for food contact. This is non-negotiable in the food, beverage, and pharmaceutical industries where preventing contamination is the highest priority.

Key Industrial Applications in Detail

While its properties are broadly applicable, PTFE packing is most heavily utilized in sectors where operational demands are highest.

The Chemical and Petrochemical Sector

This is the primary user of PTFE packing. It is specified for pumps, valves, mixers, and reactors that handle aggressive and corrosive fluids. The packing ensures a safe, reliable seal, preventing environmental and safety incidents.

Food, Beverage, and Pharmaceutical Manufacturing

In these clean industries, the primary goal is preventing contamination. PTFE packing provides a sterile, non-reactive seal in processing equipment, ensuring that the final product remains pure and safe for consumption.

Pulp and Paper Mills

The pulp and paper manufacturing process involves harsh chemicals, high pressures, and abrasive slurries. PTFE packing is used in pumps and agitators to withstand this demanding environment and minimize costly downtime.

Power Generation and General Industry

Across general manufacturing and power plants, PTFE packing is a reliable workhorse for sealing valves and pumps that handle water, steam, mild chemicals, and other utilities. Its versatility makes it a standard inventory item.

Understanding the Trade-offs

Despite its advantages, PTFE is not a universal solution. Being aware of its limitations is crucial for proper application and avoiding premature failure.

Tendency to Creep (Cold Flow)

PTFE's most significant weakness is its tendency to deform or "creep" over time under sustained compressive load, especially at elevated temperatures. This can lead to a loss of sealing pressure and potential leaks if not accounted for in the system design.

Lower Abrasion Resistance

While it has low friction, pure PTFE is a relatively soft material. It is not well-suited for sealing highly abrasive media, such as slurries containing hard particulates, which can quickly wear the packing away.

High Thermal Expansion

PTFE expands and contracts with temperature changes more than the metals it typically seals against. This high coefficient of thermal expansion must be considered during installation to ensure a consistent seal across the full operating temperature range.

Making the Right Choice for Your Application

Selecting the correct packing involves matching the material's properties to your primary operational goal.

- If your primary focus is aggressive chemical resistance: Virgin PTFE is often the default and best-in-class choice for sealing highly corrosive media where other materials would disintegrate.

- If your primary focus is product purity (food/pharma): Pure, FDA-compliant PTFE packing is essential to meet regulatory standards and guarantee the product remains uncontaminated.

- If your primary focus is high mechanical stress or abrasion: Consider a composite PTFE packing, which incorporates materials like carbon, graphite, or aramid fibers to significantly improve its strength and resistance to creep and wear.

Ultimately, understanding these core properties allows you to select not just a material, but a reliable solution engineered for your specific industrial challenge.

Summary Table:

| Industry | Primary Application | Key PTFE Benefit |

|---|---|---|

| Chemical & Petrochemical | Pumps, valves, reactors | Unmatched chemical resistance to aggressive fluids |

| Food & Beverage | Processing equipment | FDA-compliant purity, prevents contamination |

| Pharmaceutical | Manufacturing systems | Sterile, non-reactive sealing for sensitive media |

| Pulp & Paper | Pumps, agitators | Resistance to harsh chemicals and abrasive slurries |

| Power Generation & General Industry | Valves, utility pumps | Versatility, thermal stability, and reliability |

Need a reliable PTFE sealing solution tailored to your industry's demands?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including custom packing, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures a perfect fit for aggressive chemical environments, strict purity standards, or challenging mechanical conditions.

Contact us today to discuss your application and benefit from our custom fabrication capabilities!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance