You should choose a PTFE sheet over Teflon paper when your project demands maximum durability, repeated use, or involves high pressure and intense heat. A PTFE sheet is a long-term investment designed for professional or high-volume work, offering a consistent, reliable barrier that lasts for hundreds of uses. In contrast, Teflon paper serves as a cost-effective, flexible alternative for lighter jobs or less frequent tasks where longevity is not the primary concern.

The decision between a PTFE sheet and Teflon paper hinges on a simple trade-off: durability versus flexibility and cost. PTFE sheets are a robust, long-term solution for demanding applications, while Teflon paper offers a convenient, disposable option for lighter tasks.

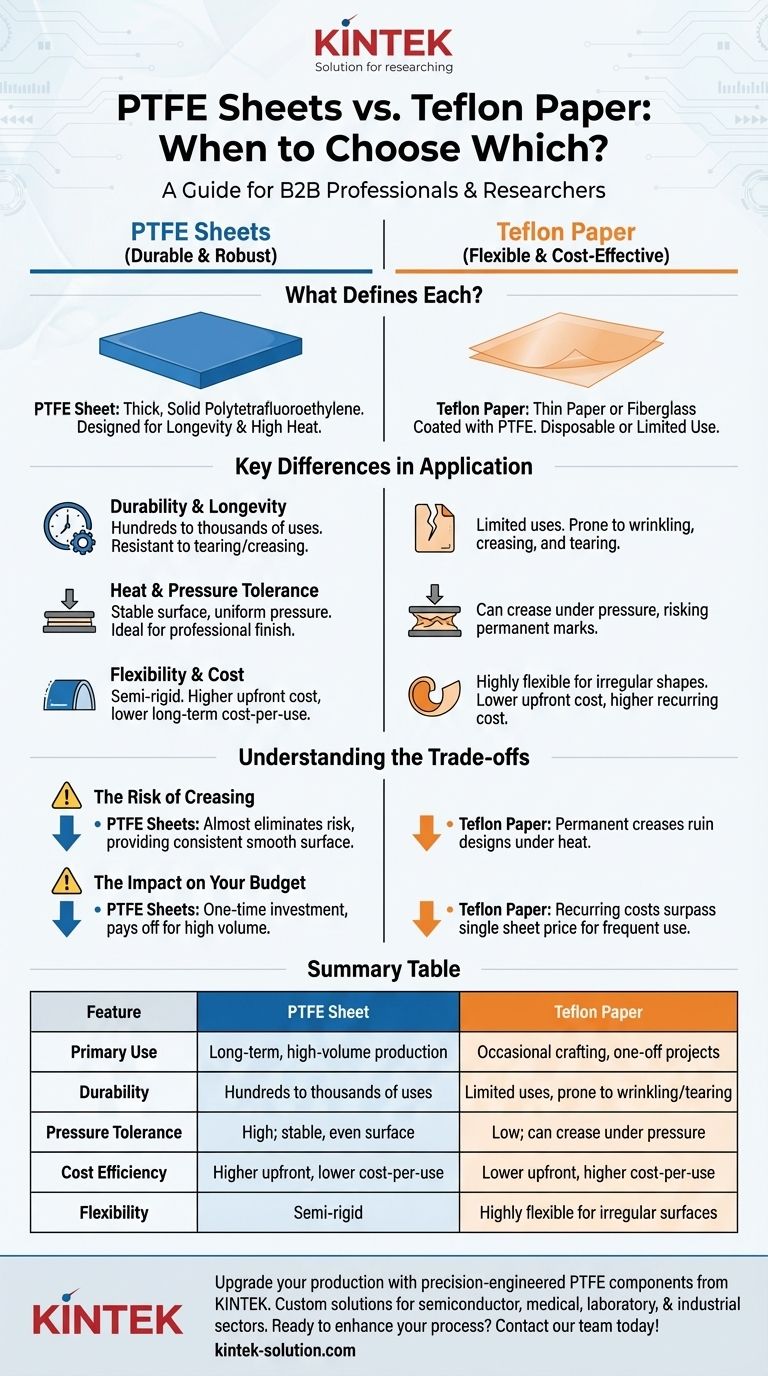

What Defines Each Material?

To make an informed choice, you must first understand the fundamental differences in how these materials are constructed and how that impacts their performance.

Understanding PTFE Sheets

A PTFE sheet is a solid, relatively thick sheet made from polytetrafluoroethylene. This is the same chemical compound known by the brand name Teflon.

These sheets are manufactured to be highly durable, semi-rigid, and exceptionally resistant to heat and chemicals. They provide a perfectly smooth, non-stick surface that is built for longevity.

Understanding "Teflon Paper"

The term "Teflon paper" typically refers to a thinner, more flexible material, often a sheet of paper or a fiberglass fabric that has been coated with PTFE.

While it offers similar non-stick and heat-resistant properties, its thin construction makes it far less durable. It is best viewed as a limited-use or disposable tool rather than a permanent piece of equipment.

Key Differences in Application

The material differences directly translate into how each performs under pressure, heat, and repeated use. This is the core of the decision-making process.

Durability and Longevity

PTFE sheets are the clear winner for long-term use. A quality sheet can withstand hundreds, if not thousands, of heat-press cycles without degrading, tearing, or creasing.

Teflon paper is prone to wrinkling, creasing, and tearing, especially under the pressure of a heat press. It is designed for a limited number of uses before it needs to be replaced.

Heat and Pressure Tolerance

Both materials handle the heat required for most applications, but their response to pressure differs significantly.

A thick PTFE sheet provides a stable, even surface that distributes pressure uniformly. This is critical for achieving a professional finish with heat transfer vinyl (HTV) or sublimation.

Thinner Teflon paper can easily wrinkle under pressure, potentially imprinting unwanted crease marks onto your garment or substrate.

Flexibility and Cost

Here, the roles reverse. Teflon paper is significantly more flexible, allowing it to conform to irregularly shaped items more easily than a semi-rigid PTFE sheet.

It also has a much lower upfront cost, making it an attractive option for hobbyists or those just starting out. However, its cost-per-use can be much higher than a PTFE sheet if you require it frequently.

Understanding the Trade-offs

Choosing the right material means being aware of the potential downsides of each option. An incorrect choice can lead to wasted materials and subpar results.

The Risk of Creasing

A permanent crease in Teflon paper is a critical failure point. If you use a wrinkled sheet in a heat press, that wrinkle's pattern will be permanently transferred to your design, ruining the item.

The semi-rigid nature of a PTFE sheet almost entirely eliminates this risk, providing a consistently smooth surface every time.

The Impact on Your Budget

The higher initial price of a PTFE sheet can be a deterrent. However, for any serious or commercial operation, it is a one-time investment that pays for itself by eliminating the need for constant re-purchasing.

Relying on Teflon paper for high-volume work will create a recurring operational cost that quickly surpasses the price of a single, durable PTFE sheet.

Making the Right Choice for Your Goal

To select the right material, match its core properties to your primary objective.

- If your primary focus is running a business or high-volume production: Invest in several PTFE sheets for their long-term durability and consistent, professional results.

- If your primary focus is occasional crafting or one-off projects: Teflon paper provides a perfectly adequate and cost-effective non-stick barrier.

- If your primary focus is protecting a curved or irregular surface: The flexibility of Teflon paper may offer a distinct advantage over a more rigid sheet.

Ultimately, understanding the material properties behind the names empowers you to choose the most effective tool for every job.

Summary Table:

| Feature | PTFE Sheet | Teflon Paper |

|---|---|---|

| Primary Use | Long-term, high-volume production | Occasional crafting, one-off projects |

| Durability | Hundreds to thousands of uses | Limited uses, prone to wrinkling/tearing |

| Pressure Tolerance | High; stable, even surface | Low; can crease under pressure |

| Cost Efficiency | Higher upfront, lower cost-per-use | Lower upfront, higher cost-per-use |

| Flexibility | Semi-rigid | Highly flexible for irregular surfaces |

Upgrade your production with precision-engineered PTFE components from KINTEK.

Whether you're in the semiconductor, medical, laboratory, or industrial sector, our custom-fabricated PTFE sheets, seals, liners, and labware are built for maximum durability and consistent performance under high pressure and heat. We specialize in creating solutions from prototypes to high-volume orders, ensuring your operations run smoothly and efficiently.

Ready to enhance your process with reliable, long-lasting PTFE solutions? Contact our team today to discuss your specific needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What environmental resistance properties do PTFE bellow seals have? Withstand Harsh Chemicals & Extreme Temperatures

- What are some examples of ePTFE applications in aerospace and automotive industries? Critical Components for Extreme Environments

- How does the spring energizer work in PTFE seals? Ensure Leak-Free Performance in Extreme Conditions

- Why are PTFE gaskets considered safe for sensitive applications? Ensure Purity and Reliability

- What are the advantages of PTFE gaskets? Superior Sealing for Extreme Chemical & Thermal Environments

- What are the benefits of using unreinforced PTFE materials? Unmatched Purity and Electrical Performance

- What are the drawbacks of using PTFE for sealing needs? The Critical Trade-offs in Chemical vs. Mechanical Performance

- What technical services are provided for PTFE product development? A Guide from Concept to Component