PTFE seals are engineered for extremes. They are specifically designed to maintain their integrity in working conditions that would cause conventional elastomeric seals to fail, including exceptionally high or low temperatures, significant pressures, and contact with aggressive chemicals.

The core value of PTFE lies in its chemical inertness and wide thermal range. However, its true potential is unlocked in engineered designs, like spring-energized seals, which compensate for the material's natural low elasticity to create a robust seal in the most demanding industrial applications.

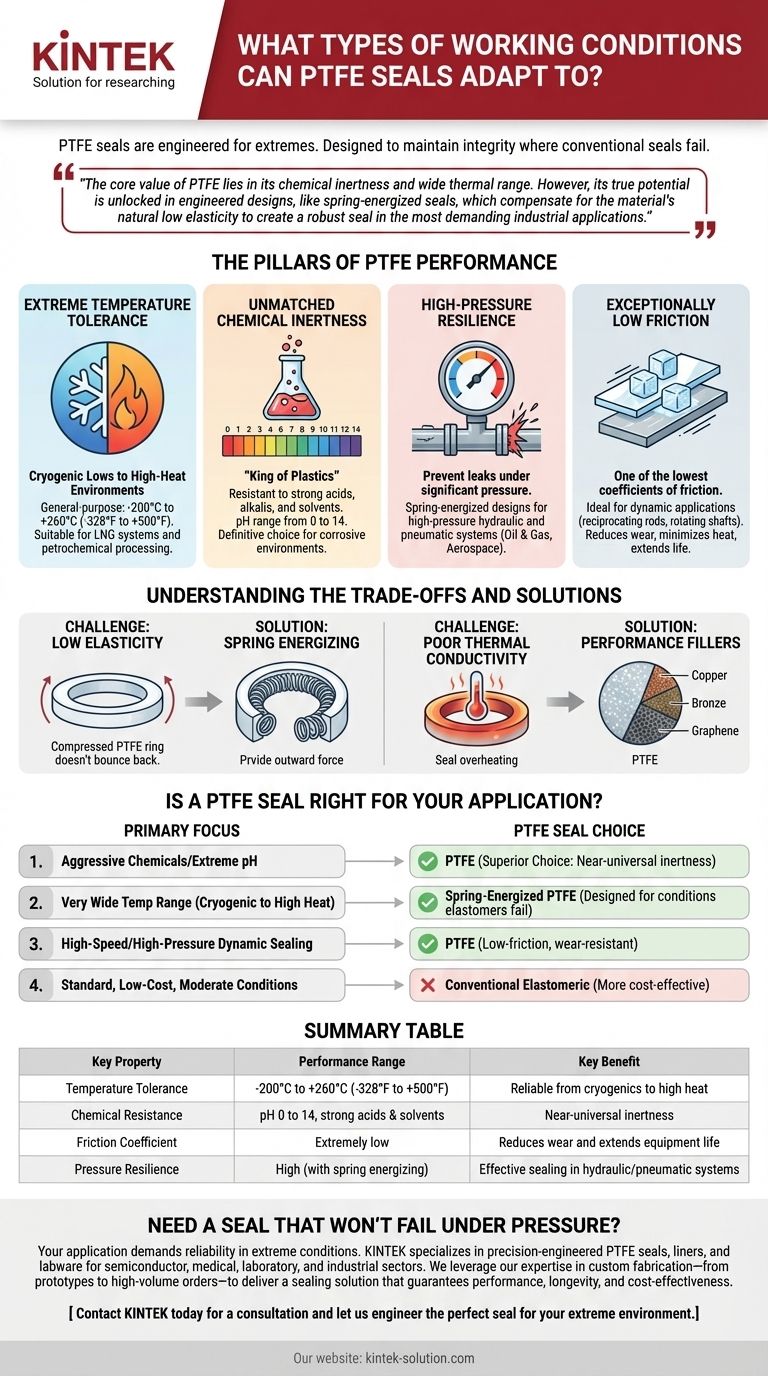

The Pillars of PTFE Performance

Polytetrafluoroethylene (PTFE) possesses a unique combination of properties that define its operational capabilities. These characteristics make it a go-to material for critical sealing challenges.

Extreme Temperature Tolerance

PTFE maintains its properties across a vast temperature spectrum, from cryogenic lows to high-heat environments.

General-purpose PTFE seals can function reliably in temperatures ranging from -200°C to +260°C (-328°F to +500°F). This makes them suitable for applications as diverse as liquefied natural gas (LNG) systems and high-temperature petrochemical processing.

Unmatched Chemical Inertness

Often called the "King of Plastics," PTFE has extremely strong carbon-fluorine bonds, rendering it resistant to almost all industrial chemicals.

It performs reliably when exposed to strong acids, alkalis, and aggressive solvents. Its ability to handle fluids with a pH range from 0 to 14 makes it a definitive choice for corrosive environments.

High-Pressure Resilience

PTFE seals are engineered to effectively prevent leaks even when subjected to significant pressurized fluids or gases.

While specific designs vary, spring-energized PTFE seals are frequently used in high-pressure hydraulic and pneumatic systems common in the oil and gas and aerospace industries.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice.

This high lubricity is ideal for dynamic applications, such as in reciprocating rods or rotating shafts. It reduces wear, minimizes heat generation, and enhances the operational life of both the seal and the equipment.

Understanding the Trade-offs and Solutions

While PTFE's core properties are exceptional, it is not a universal solution without engineering considerations. Understanding its limitations is key to applying it correctly.

The Challenge: Low Elasticity

Unlike rubber, PTFE is not naturally elastic. It does not "spring back" into shape well after being compressed, which is a critical function for a seal.

The Solution: Spring Energizing

To overcome its low elasticity, many high-performance PTFE seals incorporate a metal spring energizer.

This spring provides a constant mechanical force, pressing the seal lips against the mating surfaces. This ensures a tight, reliable seal even at low pressures or during temperature fluctuations.

The Challenge: Poor Thermal Conductivity

PTFE does not dissipate heat well, which can be a concern in very high-speed applications.

The Solution: Performance Fillers

To mitigate this, PTFE is often blended with fillers like copper, bronze, or graphene. These additives improve thermal conductivity and can also enhance wear resistance for specific applications.

The Cost Consideration

Engineered PTFE seals typically have a higher initial cost than standard elastomeric seals.

This cost is justified by their dramatically increased performance, reliability, and service life in conditions where other materials would require frequent and costly replacement.

Is a PTFE Seal Right for Your Application?

Choosing the right seal requires matching the material's strengths to your primary operational challenge.

- If your primary focus is handling aggressive chemicals or extreme pH levels: PTFE is the superior choice due to its near-universal chemical inertness.

- If your primary focus is a very wide temperature range (cryogenic to high heat): A spring-energized PTFE seal is specifically designed for these conditions where elastomers would become brittle or degrade.

- If your primary focus is high-speed or high-pressure dynamic sealing: The low-friction and wear-resistant properties of PTFE will reduce maintenance and extend equipment life.

- If your primary focus is a standard, low-cost application with moderate conditions: A conventional elastomeric seal may be a more cost-effective solution.

Ultimately, selecting a PTFE seal is a strategic decision to ensure reliability when operational conditions are simply too demanding for other materials.

Summary Table:

| Key Property | Performance Range | Key Benefit |

|---|---|---|

| Temperature Tolerance | -200°C to +260°C (-328°F to +500°F) | Reliable from cryogenics to high heat |

| Chemical Resistance | pH 0 to 14, strong acids & solvents | Near-universal inertness |

| Friction Coefficient | Extremely low | Reduces wear and extends equipment life |

| Pressure Resilience | High (with spring energizing) | Effective sealing in hydraulic/pneumatic systems |

Need a seal that won't fail under pressure?

Your application demands reliability in extreme conditions. KINTEK specializes in precision-engineered PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. We leverage our expertise in custom fabrication—from prototypes to high-volume orders—to deliver a sealing solution that guarantees performance, longevity, and cost-effectiveness for your most critical operations.

Contact KINTEK today for a consultation and let us engineer the perfect seal for your extreme environment.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What are the benefits of using PTFE seals in demanding industries? Solve Extreme Sealing Challenges

- What is the overall operating temperature range for PTFE seals, gaskets, and O-rings? Achieve Sealing Integrity from -200°C to +260°C

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions