PTFE can be reliably manufactured into a wide range of high-performance parts when subjected to stringent quality control. Common examples include precision bearings, high-purity tubing, specialized tapes, and chemically resistant valves and bushes. The success of these components hinges on a manufacturing process that verifies quality at every stage, ensuring they leverage PTFE's exceptional heat and chemical resistance.

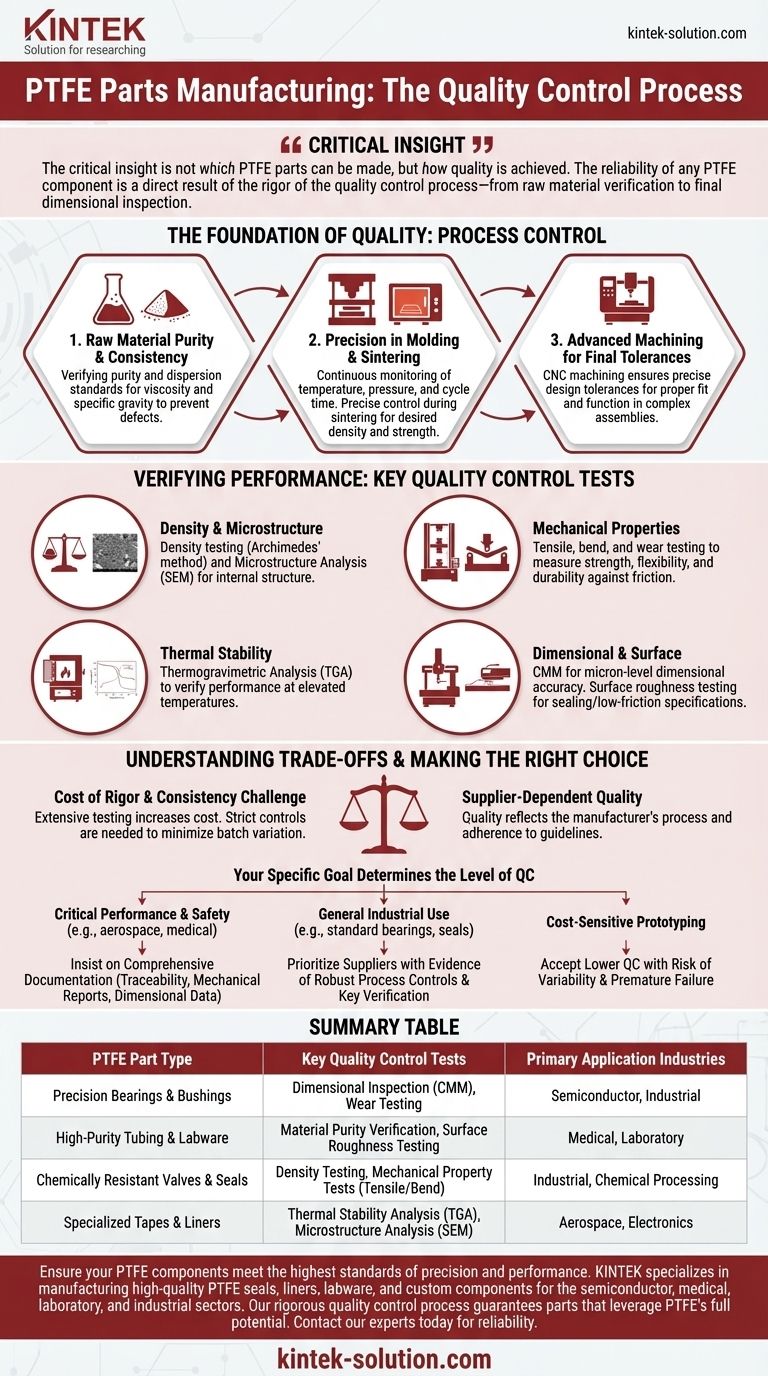

The critical insight is not which PTFE parts can be made, but how quality is achieved. The reliability of any PTFE component is a direct result of the rigor of the quality control process—from raw material verification to final dimensional inspection.

The Foundation of Quality: Process Control

True quality control is not just a final inspection; it is embedded throughout the entire manufacturing lifecycle. Each step is critical for producing a component that performs as expected under demanding conditions.

Raw Material Purity and Consistency

The process begins with the raw PTFE material. Quality control measures ensure the purity of all ingredients and verify that PTFE dispersions meet exact standards for viscosity and specific gravity. This foundational step prevents defects before they ever form.

Precision in Molding and Sintering

During the molding stage, temperature, pressure, and cycle time are continuously monitored and controlled. The subsequent sintering process, which fuses the PTFE particles, requires precise control over temperature and duration to achieve the desired material density and strength.

Advanced Machining for Final Tolerances

For components requiring exact dimensions, like bushes or valve seats, advanced CNC machining is employed. This step ensures that the final part meets precise design tolerances, which is crucial for proper fit and function in complex assemblies.

Verifying Performance: Key Quality Control Tests

Once a part is formed, it undergoes a series of tests to validate its physical and mechanical properties. These empirical measurements confirm that the process controls were effective.

Density and Microstructure Analysis

Density testing, often using Archimedes’ method, confirms the part is free of voids and has been properly sintered. For more advanced applications, microstructure analysis using Scanning Electron Microscopy (SEM) can be used to examine the internal structure of the material.

Mechanical Property Testing

To ensure the part can withstand real-world stress, it is subjected to a battery of mechanical tests. These include tensile, bend, and wear testing to measure its strength, flexibility, and durability against friction.

Thermal Stability Assessment

Given that PTFE is often chosen for high-temperature applications, its thermal stability is paramount. Techniques like Thermogravimetric Analysis (TGA) verify the material's performance at elevated temperatures, ensuring it will not degrade in its operational environment.

Dimensional and Surface Inspection

Finally, the part's physical dimensions and surface quality are verified. A Coordinate Measuring Machine (CMM) ensures dimensional accuracy to the micron level, while surface roughness testing confirms the finish meets the required specifications for sealing or low-friction applications.

Understanding the Trade-offs

While comprehensive quality control ensures superior performance, it's important to understand the associated implications.

The Cost of Rigor

Extensive testing and process monitoring require significant investment in equipment and expertise. Consequently, a PTFE part with full quality documentation will have a higher cost than a component produced with minimal oversight.

The Challenge of Consistency

PTFE manufacturing is highly sensitive to process variables. Without the strict controls mentioned, properties can vary significantly between batches. This makes supplier selection and their commitment to quality paramount.

Supplier-Dependent Quality

The "quality" is not inherent in the PTFE material itself, but in the manufacturer's process. A part's reliability is a direct reflection of the supplier's quality systems. For instance, manufacturers using the Teflon™ trademark must adhere to specific guidelines on factors like coating thickness and baking temperatures.

Making the Right Choice for Your Application

Your specific goal will determine the necessary level of quality control for your PTFE components.

- If your primary focus is critical performance and safety (e.g., aerospace, medical): Insist on comprehensive testing documentation from your supplier, including material traceability, mechanical property reports, and dimensional inspection data.

- If your primary focus is general industrial use (e.g., standard bearings, seals): Prioritize suppliers who can provide evidence of robust process controls and verification of key mechanical and dimensional properties.

- If your primary focus is cost-sensitive prototyping: A lower level of documented QC may be acceptable, but you must acknowledge the risk of performance variability and potential for premature failure.

By understanding the "how" behind quality control, you can confidently specify PTFE components that meet your exact performance standards.

Summary Table:

| PTFE Part Type | Key Quality Control Tests | Primary Application Industries |

|---|---|---|

| Precision Bearings & Bushings | Dimensional Inspection (CMM), Wear Testing | Semiconductor, Industrial |

| High-Purity Tubing & Labware | Material Purity Verification, Surface Roughness Testing | Medical, Laboratory |

| Chemically Resistant Valves & Seals | Density Testing, Mechanical Property Tests (Tensile/Bend) | Industrial, Chemical Processing |

| Specialized Tapes & Liners | Thermal Stability Analysis (TGA), Microstructure Analysis (SEM) | Aerospace, Electronics |

Ensure your PTFE components meet the highest standards of precision and performance. KINTEK specializes in manufacturing high-quality PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our rigorous quality control process—from raw material verification to final dimensional inspection—guarantees parts that leverage PTFE's full potential for heat and chemical resistance. Whether you need prototypes or high-volume orders, we deliver reliability. Contact our experts today to discuss your specific requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications