To enhance its performance in demanding applications, Polytetrafluoroethylene (PTFE) can be blended with a variety of filler materials. The most common fillings incorporated into PTFE seals include glass fiber, carbon, and specialized polymers, each selected to improve specific mechanical or thermal properties.

The core takeaway is that while pure PTFE offers unmatched chemical resistance and low friction, it is inherently soft and prone to deformation. Fillers are systematically added to overcome these limitations, creating a composite material engineered for specific high-stress applications.

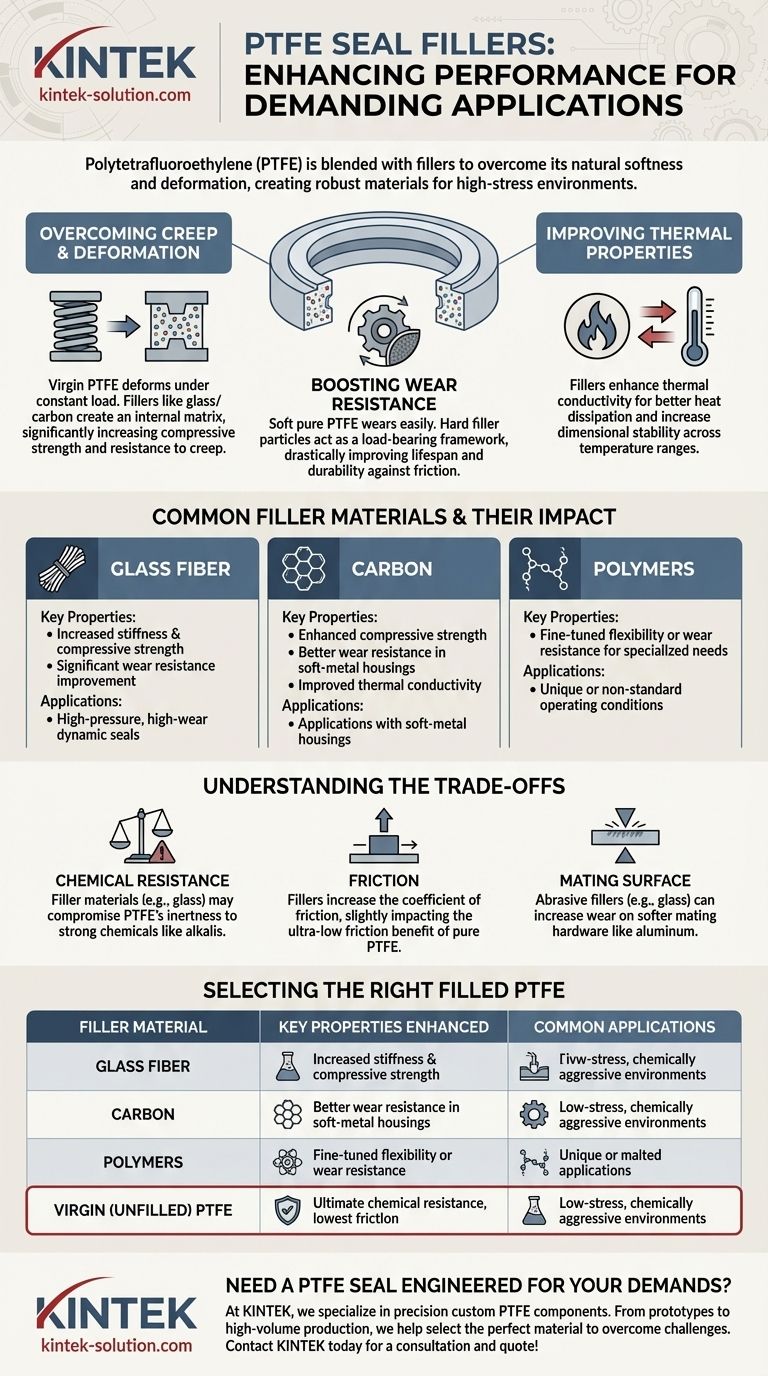

The Fundamental Purpose of PTFE Fillers

Pure, or "virgin," PTFE is a remarkable material. Its unique molecular structure gives it an extremely low coefficient of friction, a wide operating temperature range, and near-universal chemical inertness. However, these same properties make it mechanically weak.

Overcoming Creep and Deformation

Virgin PTFE has a tendency to "creep," meaning it slowly deforms over time when subjected to a constant load. Adding rigid fillers like glass or carbon creates an internal matrix that significantly increases the material's compressive strength and resistance to deformation under load.

Boosting Wear Resistance

The softness of pure PTFE makes it susceptible to abrasion and wear in dynamic sealing applications. Hard filler particles distributed throughout the PTFE base act as a load-bearing framework, drastically improving the seal's lifespan and durability against friction.

Improving Thermal Properties

Fillers can also enhance the thermal characteristics of PTFE. They can improve thermal conductivity, allowing heat to dissipate more effectively from the sealing interface, and increase dimensional stability across a range of temperatures.

Common Filler Materials and Their Impact

The choice of filler is a critical engineering decision, as each material imparts a distinct set of properties to the final PTFE composite.

Glass Fiber

Glass fiber is a common, cost-effective filler. It is primarily used to increase stiffness and compressive strength while significantly improving wear resistance. This makes it ideal for many high-pressure and high-wear applications.

Carbon

Carbon, often in fiber or powder form, is another widely used filler. It enhances compressive strength and provides better wear resistance than glass in certain conditions, particularly in soft-metal housing applications. It also improves thermal conductivity.

Polymers

Other high-performance polymers can be blended with PTFE to achieve specific characteristics. This approach can fine-tune properties like flexibility or wear resistance for specialized applications where standard fillers are not suitable.

Understanding the Trade-offs

Modifying PTFE with fillers is not without compromises. Enhancing one property often comes at the expense of another, and understanding these trade-offs is crucial for proper seal selection.

The Impact on Chemical Resistance

While PTFE itself is nearly inert, the filler material may not be. Adding glass fiber, for example, can compromise the seal's resistance to strong alkalis or hydrofluoric acid, which would not affect virgin PTFE.

The Effect on Friction

A core benefit of PTFE is its extremely low friction. Nearly all fillers will increase the coefficient of friction to some degree. The gain in wear resistance must be weighed against this slight increase in operational friction.

Mating Surface Considerations

Abrasive fillers like glass can increase wear on the mating hardware surface, particularly softer metals like aluminum. For these applications, a less abrasive filler like carbon or a specialized polymer blend is often a better choice.

Selecting the Right Filled PTFE for Your Application

The optimal seal material is always a function of the specific service conditions, including temperature, pressure, media, and dynamic motion.

- If your primary focus is high wear resistance and compressive strength: A glass-filled or carbon-filled PTFE is the standard choice.

- If your primary focus is reducing deformation (creep) under heavy static loads: Any filled PTFE compound will dramatically outperform virgin material.

- If your primary focus is ultimate chemical purity and the lowest possible friction: Virgin (unfilled) PTFE remains the superior option, provided the mechanical demands are low.

Choosing the right filler transforms a versatile material into a high-performance, application-specific solution.

Summary Table:

| Filler Material | Key Properties Enhanced | Common Applications |

|---|---|---|

| Glass Fiber | Wear resistance, compressive strength, stiffness | High-pressure, high-wear dynamic seals |

| Carbon | Wear resistance, thermal conductivity, compressive strength | Applications with soft-metal housings |

| Polymers | Fine-tuned flexibility, specialized wear resistance | Unique or non-standard operating conditions |

| Virgin (Unfilled) PTFE | Ultimate chemical resistance, lowest friction | Low-stress, chemically aggressive environments |

Need a PTFE Seal Engineered for Your Specific Demands?

At KINTEK, we specialize in precision manufacturing of custom PTFE components, including seals, liners, and labware. Whether you require standard glass-filled compounds or a proprietary polymer blend to meet unique challenges in the semiconductor, medical, laboratory, or industrial sectors, our expertise ensures optimal performance.

We handle everything from initial prototypes to high-volume production, prioritizing precision and durability. Let our team help you select the perfect filled PTFE material to overcome creep, boost wear resistance, and extend seal life.

Contact KINTEK today for a consultation and quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry