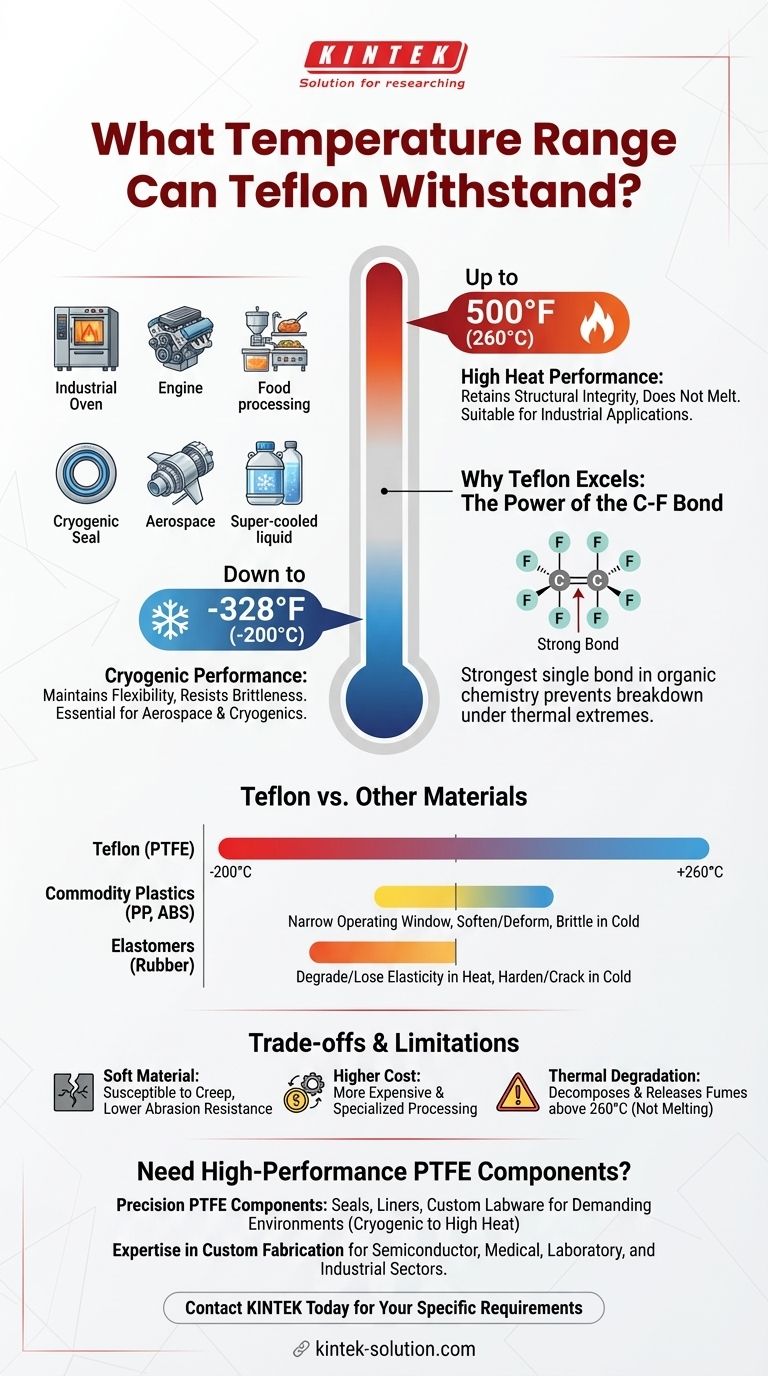

The operational temperature range of Teflon is exceptionally wide. In its pure form, known as Polytetrafluoroethylene (PTFE), it can withstand continuous service temperatures up to 500°F (260°C) without losing its structural integrity. It performs just as reliably in extreme cold, remaining functional at cryogenic temperatures as low as -328°F (-200°C).

The key takeaway is that Teflon's thermal stability is one of its defining features. Its unique molecular structure allows it to operate reliably in a temperature window far broader than almost any other common plastic or elastomer, making it a default choice for extreme environmental conditions.

Why Teflon Excels in Extreme Temperatures

The numbers are impressive, but understanding why PTFE performs so well is crucial for specifying it correctly. Its capabilities are not arbitrary; they are a direct result of its unique molecular composition.

The Power of the Carbon-Fluorine Bond

At its core, PTFE is a simple polymer made of a long chain of carbon atoms, with each carbon atom completely shielded by two fluorine atoms.

The bond between carbon and fluorine is one of the strongest single bonds in organic chemistry. This immense bond strength is what prevents the polymer chains from breaking down or degrading when subjected to thermal energy, either high or low.

Performance at High Temperatures

Teflon's upper service limit of 500°F (260°C) makes it suitable for high-heat industrial applications.

At this temperature, it retains its essential properties and does not melt. This allows it to be used reliably in components for engines, industrial ovens, food processing systems, and manufacturing equipment where other plastics would fail.

Performance at Cryogenic Temperatures

Many materials become extremely brittle and fracture easily at very low temperatures. Teflon, however, maintains its flexibility and durability down to -328°F (-200°C).

This makes it an essential material in cryogenic applications, such as seals and components used in the aerospace industry, where exposure to super-cooled liquids is common.

How Teflon Compares to Other Materials

Context is critical when evaluating a material. Teflon's thermal range is best understood when compared to other common engineering materials.

Superiority Over Other Plastics

Commodity plastics like Polypropylene and ABS have a much narrower operating window. They begin to soften and deform at temperatures far below Teflon's limit and become brittle long before reaching cryogenic levels.

Advantages Over Elastomers

Elastomers, or rubbers, are known for flexibility but have significant thermal limitations. They degrade and lose their elasticity at high temperatures and will harden and crack in deep cold, a failure mode that Teflon is highly resistant to.

Understanding the Trade-offs and Limitations

No material is perfect for every situation. While Teflon's thermal performance is elite, it's important to be aware of its practical limitations to avoid misapplication.

Thermal Degradation, Not Melting

Teflon does not have a true melting point like many plastics. When heated far beyond its 260°C service limit, it does not turn into a liquid. Instead, it begins to degrade and can release potentially hazardous fumes.

Mechanical Properties

While thermally stable, standard PTFE is a relatively soft material. It can be susceptible to "creep" (slow deformation under constant load) and has lower abrasion resistance compared to harder engineering plastics.

Cost and Processing

Teflon is a high-performance polymer and is generally more expensive than common plastics. It also requires specialized processing techniques, which can add to the final component cost.

Making the Right Choice for Your Application

Selecting the correct material requires balancing performance requirements with practical constraints. Use these guidelines to decide if Teflon is the appropriate choice.

- If your primary focus is extreme temperature stability (-200°C to +260°C): Teflon is an ideal choice, offering reliable performance where nearly all other plastics and elastomers would fail.

- If your primary focus is high mechanical strength or wear resistance: You should consider either a "filled" grade of Teflon (which includes additives like glass or carbon) or an alternative high-performance polymer.

- If your primary focus is cost-effectiveness for a moderate temperature range: A more common and less expensive plastic like Polypropylene or Nylon may be a more suitable and economical solution.

By understanding both its exceptional thermal range and its practical limitations, you can confidently specify Teflon for the most demanding environments.

Summary Table:

| Temperature Range | Performance | Key Applications |

|---|---|---|

| Up to 500°F (260°C) | Retains structural integrity, does not melt. | Industrial ovens, engines, food processing. |

| Down to -328°F (-200°C) | Maintains flexibility, resists brittleness. | Cryogenic seals, aerospace components. |

Need High-Performance PTFE Components for Extreme Temperatures?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—that reliably perform in the most demanding thermal environments, from cryogenic cold to high heat. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get the exact solution for your application in the semiconductor, medical, laboratory, and industrial sectors.

Contact KINTEK today to discuss your specific requirements and leverage our material science expertise for your most critical projects.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- How does Teflon resist corrosion and chemicals? Unlock the Secret of its Molecular Shield

- How does PTFE contribute to environmental benefits? Durability, Efficiency, and Contamination Prevention

- How was Teflon discovered and what was its initial use? From Lab Accident to Wartime Innovation

- What are the advantages of using PTFE/Teflon? Unlock Superior Chemical & Thermal Stability

- Why is PTFE approved for medical implants? Leveraging Biocompatibility for Medical Devices

- What are the thermal and chemical stability properties of PTFE? Unmatched Resistance for Demanding Applications

- What are some emerging applications of PTFE? Discover Its Critical Role in Aerospace, Medical, and Semiconductor Tech

- Why is PTFE suitable for electrical applications? Discover Its Superior Insulating Properties