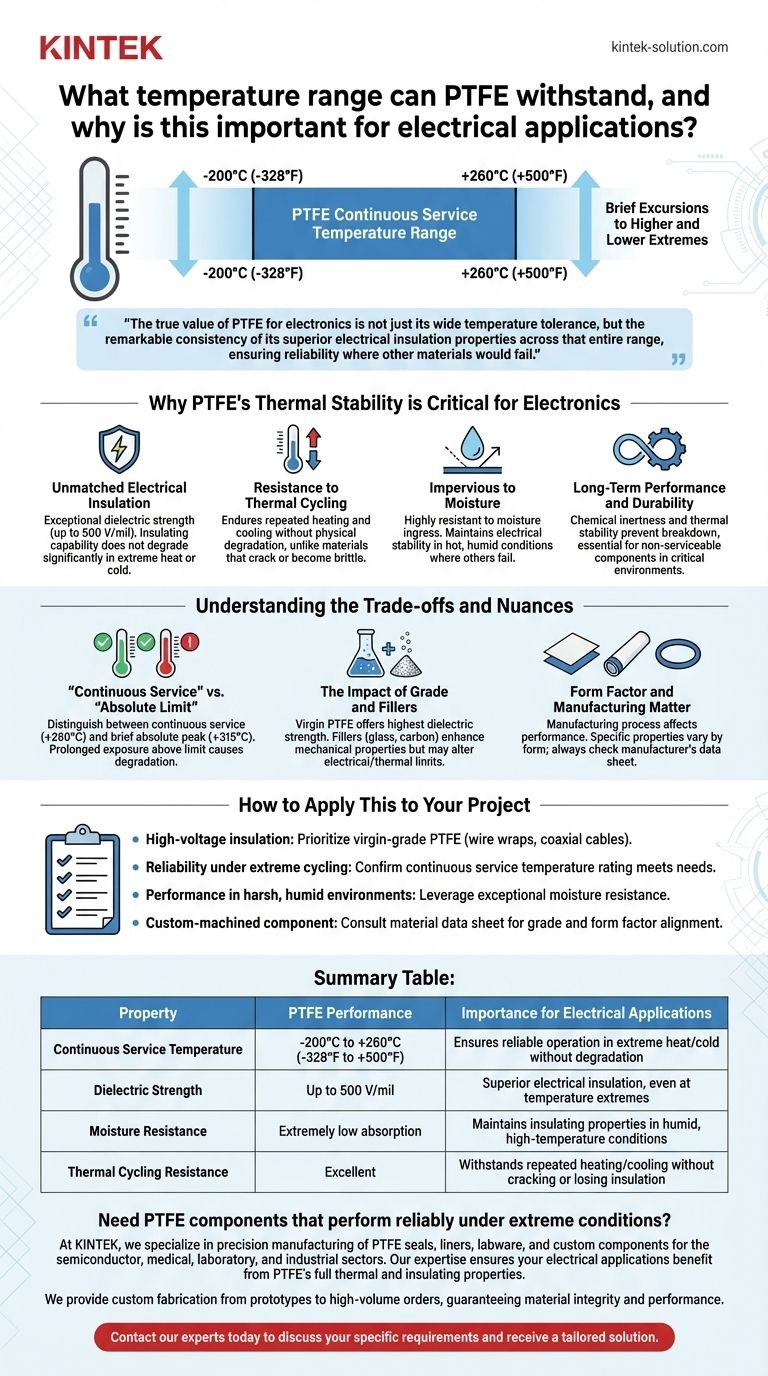

In practical terms, Polytetrafluoroethylene (PTFE) has a continuous service temperature range of approximately -200°C to +260°C (-328°F to +500°F). While it can withstand brief excursions to higher and lower extremes, this operational range is what makes it a cornerstone material for high-performance electrical applications where consistent performance under thermal stress is non-negotiable.

The true value of PTFE for electronics is not just its wide temperature tolerance, but the remarkable consistency of its superior electrical insulation properties across that entire range, ensuring reliability where other materials would fail.

Why PTFE's Thermal Stability is Critical for Electronics

The performance of an electrical component is only as reliable as its weakest link, which is often the insulating material. PTFE's ability to maintain its integrity in extreme temperatures directly translates to safer, more durable, and more reliable electronic systems.

Unmatched Electrical Insulation

PTFE is one of the best electrical insulators known, with exceptional dielectric strength. It can insulate up to 500 volts per mil of thickness.

Crucially, this insulating capability does not significantly degrade when the material is exposed to high heat or extreme cold, preventing short circuits and signal interference in demanding environments.

Resistance to Thermal Cycling

Many applications involve repeated heating and cooling. This thermal cycling can cause lesser materials to become brittle, crack, or lose their insulating properties over time.

PTFE's stable molecular structure allows it to endure these cycles without physical degradation, making it ideal for aerospace, automotive, and industrial electronics that experience frequent temperature swings.

Impervious to Moisture

Temperature and moisture are often linked challenges. High-temperature environments can accelerate moisture absorption in many plastics, compromising their ability to insulate.

PTFE is highly resistant to moisture ingress. This ensures its electrical properties remain stable even in hot, humid conditions, a characteristic that makes it far more durable than materials like nylon or PVC.

Long-Term Performance and Durability

The combination of thermal stability and chemical inertness means PTFE does not easily break down. This longevity is essential for components that are difficult or impossible to service, such as those in satellites, downhole drilling equipment, or complex military hardware.

Understanding the Trade-offs and Nuances

While PTFE's properties are exceptional, a nuanced understanding is required for proper application. The headline temperature range is not the full story.

"Continuous Service" vs. "Absolute Limit"

It is critical to distinguish between a material's continuous service temperature and its absolute peak temperature. The widely cited +260°C is for continuous, long-term operation.

While some data shows PTFE can withstand temperatures up to 315°C (600°F), prolonged exposure above its service limit can lead to accelerated degradation and the release of fumes.

The Impact of Grade and Fillers

The electrical and thermal properties of PTFE can be altered by its formulation. Virgin PTFE offers the highest dielectric strength.

However, adding fillers like glass, carbon, or bronze can enhance mechanical properties like wear resistance but may alter the electrical characteristics and precise temperature limits.

Form Factor and Manufacturing Matter

The manufacturing process impacts final performance. A molded sheet may have slightly different properties than thin-walled extruded tubing or a machined insulator.

The specified temperature range for a PTFE O-ring, for example, may be narrower than that for a solid block due to the different mechanical stresses involved in its application. Always refer to the manufacturer's data sheet for the specific product form you are using.

How to Apply This to Your Project

Selecting the right material requires matching its specific properties to your primary goal.

- If your primary focus is high-voltage insulation: Prioritize virgin-grade PTFE for its superior dielectric strength, especially in wire wraps, coaxial cables, and standoff insulators.

- If your primary focus is reliability under extreme temperature cycling: Confirm the component's continuous service temperature rating meets your operational needs, not just its peak limit.

- If your primary focus is performance in harsh, humid environments: Leverage PTFE's exceptional moisture resistance as a key advantage over other plastics that may degrade over time.

- If your primary focus is a custom-machined component: Always consult the material data sheet for the specific grade and form factor to ensure its properties align with your design requirements.

Ultimately, understanding these details allows you to leverage PTFE's exceptional thermal and electrical properties with confidence and precision.

Summary Table:

| Property | PTFE Performance | Importance for Electrical Applications |

|---|---|---|

| Continuous Service Temperature | -200°C to +260°C (-328°F to +500°F) | Ensures reliable operation in extreme heat/cold without degradation |

| Dielectric Strength | Up to 500 V/mil | Superior electrical insulation, even at temperature extremes |

| Moisture Resistance | Extremely low absorption | Maintains insulating properties in humid, high-temperature conditions |

| Thermal Cycling Resistance | Excellent | Withstands repeated heating/cooling without cracking or losing insulation |

Need PTFE components that perform reliably under extreme conditions?

At KINTEK, we specialize in precision manufacturing of PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your electrical applications benefit from PTFE's full thermal and insulating properties.

We provide custom fabrication from prototypes to high-volume orders, guaranteeing the material integrity and performance your critical projects demand.

Contact our experts today to discuss your specific requirements and receive a tailored solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications