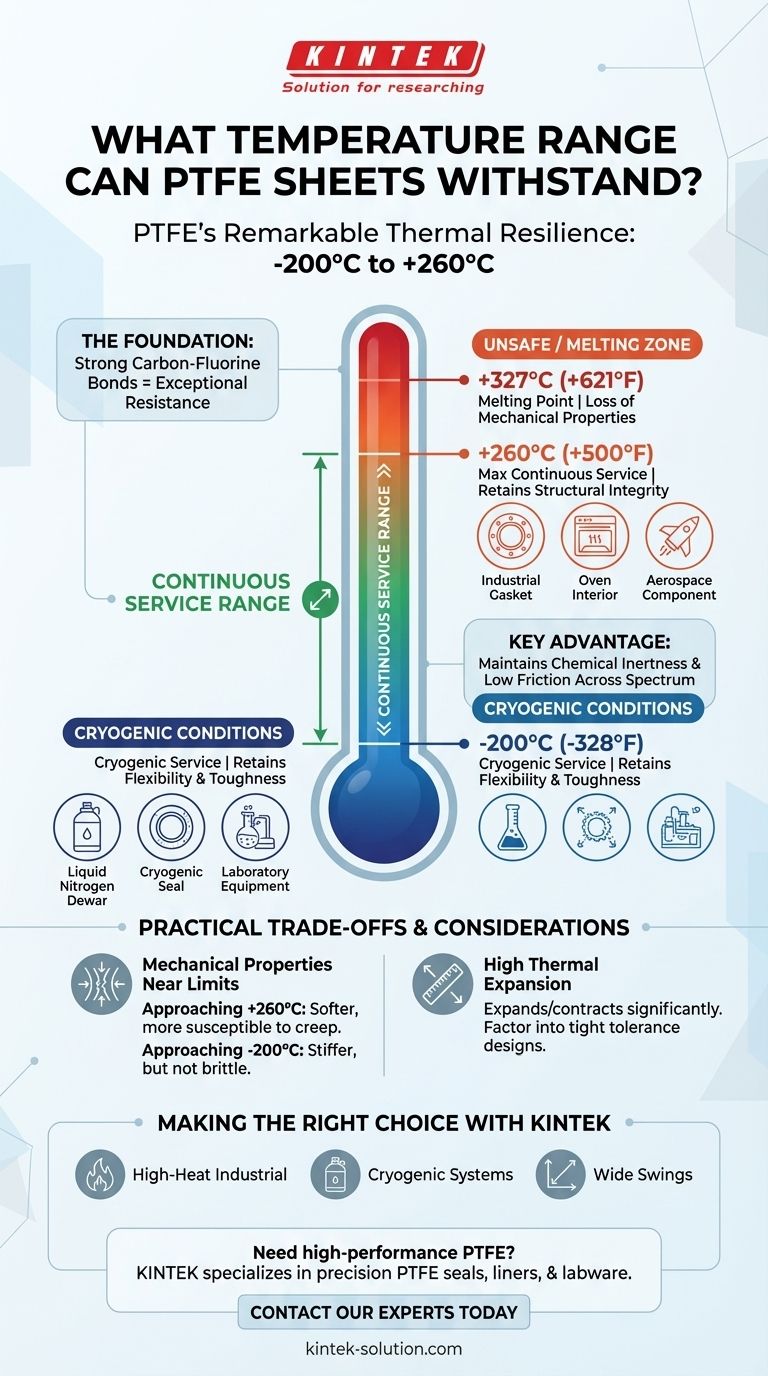

At its core, Polytetrafluoroethylene (PTFE) is defined by its remarkable thermal resilience. PTFE sheets can reliably operate within an extremely wide temperature range, from a cryogenic low of -200°C (-328°F) to a continuous high of +260°C (+500°F). This stability makes it one of the most versatile polymers for applications involving extreme thermal stress.

The critical insight is not just that PTFE survives extreme temperatures, but that it maintains its essential properties—like chemical inertness and low friction—across this entire spectrum, a feat most other polymers cannot achieve.

The Foundation of PTFE's Thermal Stability

Understanding the limits of PTFE is crucial for proper material selection. The material's molecular structure, composed of strong carbon-fluorine bonds, is the source of its exceptional thermal and chemical resistance.

The Upper Temperature Limit: Continuous Service at 260°C (500°F)

The widely cited upper limit of 260°C (500°F) represents the maximum temperature for continuous, long-term service. At this temperature, the material retains its structural integrity and performance characteristics without significant degradation.

This makes it an ideal material for high-heat applications such as gaskets in industrial machinery, non-stick surfaces in ovens, and insulators in aerospace components.

The Distinction Between Service and Melting Temperatures

It is vital to distinguish the service temperature from the melting point. PTFE has a much higher melting point of approximately 327°C (621°F).

However, operating the material above its 260°C service limit will cause it to lose its mechanical properties, potentially off-gas, and degrade long before it physically melts. The service limit is the safe, reliable boundary for engineering applications.

The Lower Temperature Limit: Performance in Cryogenic Conditions

At the other end of the spectrum, PTFE performs exceptionally well in extreme cold. It can withstand temperatures as low as -200°C (-328°F).

Unlike many plastics and elastomers that become extremely brittle and shatter at such low temperatures, PTFE retains a useful degree of flexibility and toughness, making it suitable for cryogenic seals and components.

Why This Range Matters in Practice

The sheer breadth of PTFE's operating window sets it apart from nearly all other common polymers, enabling its use in environments where other materials would instantly fail.

A Broader Spectrum Than Other Polymers

Commodity plastics like Polypropylene or ABS have much narrower thermal windows, often failing well below 100°C. Even many high-performance elastomers cannot match the combined high-heat and cryogenic resistance of PTFE.

Ensuring Consistent Performance

The key advantage is reliability. An engineer can specify PTFE for a component that will experience wide temperature swings and be confident that its core properties—particularly its unmatched chemical resistance and low coefficient of friction—will remain stable and predictable.

Understanding the Practical Trade-offs

While its thermal range is impressive, no material is without limitations. An objective assessment requires acknowledging its behavior at the temperature extremes.

Mechanical Properties Near Temperature Limits

PTFE is not perfectly rigid, and its mechanical properties are temperature-dependent. As it approaches its upper service limit of 260°C, it will become softer and more susceptible to deformation under load (a phenomenon known as creep).

Conversely, as it approaches cryogenic temperatures, it will become significantly stiffer and less flexible, though it resists becoming brittle.

High Coefficient of Thermal Expansion

PTFE expands and contracts with temperature changes more than metals do. This high coefficient of thermal expansion must be factored into any design with tight tolerances to avoid binding or failure when the part undergoes a significant temperature swing.

Making the Right Choice for Your Application

Your specific goal will determine how you leverage PTFE's unique thermal properties.

- If your primary focus is high-heat industrial processes: PTFE is an excellent choice for continuous use up to 260°C (500°F), ideal for gaskets, seals, and non-stick surfaces.

- If your primary focus is cryogenic systems: PTFE's ability to resist embrittlement down to -200°C (-328°F) makes it a reliable material for components used with liquid nitrogen or in other deep-cold environments.

- If your primary focus is applications with wide temperature swings: You must account for PTFE's thermal expansion in your design to ensure your component maintains its intended tolerances and performance.

Ultimately, PTFE's exceptional temperature range provides a level of operational security that is difficult to find in any other polymer.

Summary Table:

| Temperature Limit | Condition | Key Behavior |

|---|---|---|

| +260°C (+500°F) | Continuous Service | Retains structural integrity and performance without significant degradation. |

| +327°C (+621°F) | Melting Point | Material begins to melt and lose mechanical properties. |

| -200°C (-328°F) | Cryogenic Service | Retains flexibility and toughness, resists embrittlement. |

Need high-performance PTFE components for extreme temperatures?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, and labware that deliver reliable performance from cryogenic conditions to high-heat industrial processes. Our custom fabrication services ensure your components meet exact specifications, whether you require prototypes or high-volume orders for the semiconductor, medical, or laboratory industries.

Contact our experts today to discuss how our PTFE solutions can bring thermal stability and security to your application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry