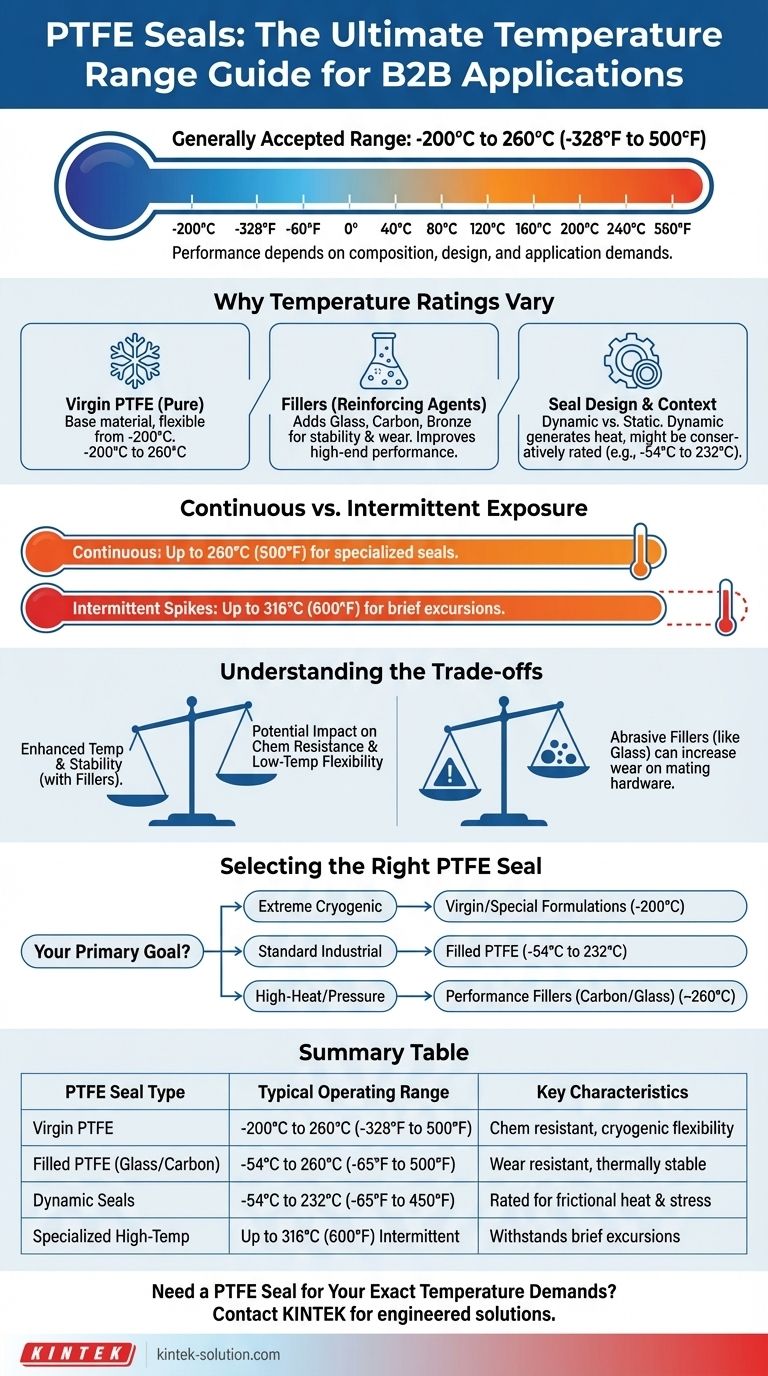

In short, PTFE seals operate within a very wide temperature range. The generally accepted range for the material is from -200°C to 260°C (-328°F to 500°F). However, the precise operational temperature a specific seal can handle is not a single number; it depends heavily on the seal’s composition, design, and the demands of the application.

The apparent variation in temperature ratings for PTFE seals is not an error but a reflection of a critical fact: the addition of fillers and the specific seal design dictate the final performance. Understanding these factors is key to selecting a seal that will not fail in your operating environment.

Why Temperature Ratings Vary for PTFE Seals

You will encounter different temperature ratings for PTFE seals because "PTFE" is often a base material that is modified for specific purposes. The material's inherent capabilities are tailored to meet the demands of an application, from cryogenic freezing to high-heat industrial processes.

The Baseline: Virgin PTFE

Virgin PTFE, which is pure, unfilled polytetrafluoroethylene, establishes the foundational temperature range. This material maintains its integrity and mechanical properties from approximately -200°C to 260°C (-328°F to 500°F).

Even at cryogenic temperatures like -196°C, it retains a useful degree of flexibility and does not become brittle like many other polymers.

The Role of Fillers (Reinforcing Agents)

Most high-performance PTFE seals are not made from virgin PTFE. They contain fillers—such as glass fiber, carbon, graphite, or bronze—to enhance specific properties.

These fillers improve characteristics like wear resistance, deformation strength, and, critically, thermal stability. A glass-filled PTFE, for example, will handle temperatures at the higher end of the spectrum with greater stability than its virgin counterpart.

Seal Design and Application Context

The theoretical temperature range of the material is different from the functional range of an assembled seal. A dynamic seal, like a rotary lip seal, generates frictional heat and is under constant mechanical stress.

For this reason, a standard PTFE lip seal might be rated more conservatively, for example, from -54°C to 232°C (-65°F to 450°F), to ensure a long service life under dynamic loads. A static seal, like a gasket, may be able to operate closer to the material's theoretical limits.

Continuous vs. Intermittent Temperature Exposure

It is crucial to distinguish between continuous operating temperature and short-term spikes. Many specialized PTFE seals can operate continuously up to 260°C (500°F).

However, some formulations are engineered to withstand brief, intermittent temperature excursions as high as 316°C (600°F) without catastrophic failure. This capability is vital for systems that experience occasional temperature surges.

Understanding the Trade-offs

Optimizing a seal for temperature performance involves balancing competing properties. There is no single "best" formulation for all scenarios.

Enhanced Temperature vs. Other Properties

While fillers boost thermal stability, they can slightly alter other characteristics. For example, some fillers may reduce the seal's broad chemical resistance in certain aggressive media or decrease its flexibility at the lowest temperature extremes.

The Impact of Abrasive Fillers

Fillers that significantly increase wear resistance, such as glass fiber, can be more abrasive than virgin PTFE. This must be considered in dynamic applications, as an improperly matched seal could increase wear on the mating hardware, such as a rotating shaft.

Selecting the Right PTFE Seal for Your Temperature Needs

To choose correctly, you must match the seal's specific formulation to your primary operational goal.

- If your primary focus is extreme cryogenic performance: Seek out virgin or specially formulated PTFE grades designed to maintain seal integrity and flexibility down to -200°C.

- If your primary focus is standard industrial use (e.g., hydraulics): A standard filled PTFE seal with a range of -54°C to 232°C (-65°F to 450°F) provides a reliable and safe operating window.

- If your primary focus is high-heat and high-pressure environments: Specify a seal with a performance filler like carbon or glass to ensure stability and reliability approaching the 260°C (500°F) limit.

Ultimately, defining your specific operating temperature range is the first step to engineering a reliable and long-lasting sealing solution.

Summary Table:

| PTFE Seal Type | Typical Operating Temperature Range | Key Characteristics |

|---|---|---|

| Virgin PTFE | -200°C to 260°C (-328°F to 500°F) | Excellent chemical resistance, cryogenic flexibility |

| Filled PTFE (e.g., Glass/Carbon) | -54°C to 260°C (-65°F to 500°F) | Enhanced wear resistance, improved thermal stability |

| Dynamic Seals | -54°C to 232°C (-65°F to 450°F) | Rated for frictional heat and mechanical stress |

| Specialized High-Temp | Up to 316°C (600°F) intermittent | Withstands brief temperature excursions |

Need a PTFE Seal That Withstands Your Exact Temperature Demands?

At KINTEK, we don't just sell seals; we engineer solutions. Whether your application operates in cryogenic conditions down to -200°C or high-heat environments up to 260°C and beyond, our expertise in custom PTFE fabrication ensures you get a seal perfectly matched to your temperature range, pressure, and chemical exposure.

We specialize in manufacturing high-precision PTFE components (seals, liners, labware) for the semiconductor, medical, laboratory, and industrial sectors. From prototypes to high-volume orders, we prioritize performance and reliability.

Contact our engineering team today for a custom solution that guarantees performance and longevity.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key steps for properly installing PTFE seals? Ensure a Leak-Free, Long-Lasting Seal

- How do PTFE seals perform under pressurized conditions? Achieving Reliable Sealing in Demanding Environments

- What are the benefits of using PTFE seals in demanding industries? Solve Extreme Sealing Challenges

- What is the overall operating temperature range for PTFE seals, gaskets, and O-rings? Achieve Sealing Integrity from -200°C to +260°C

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance