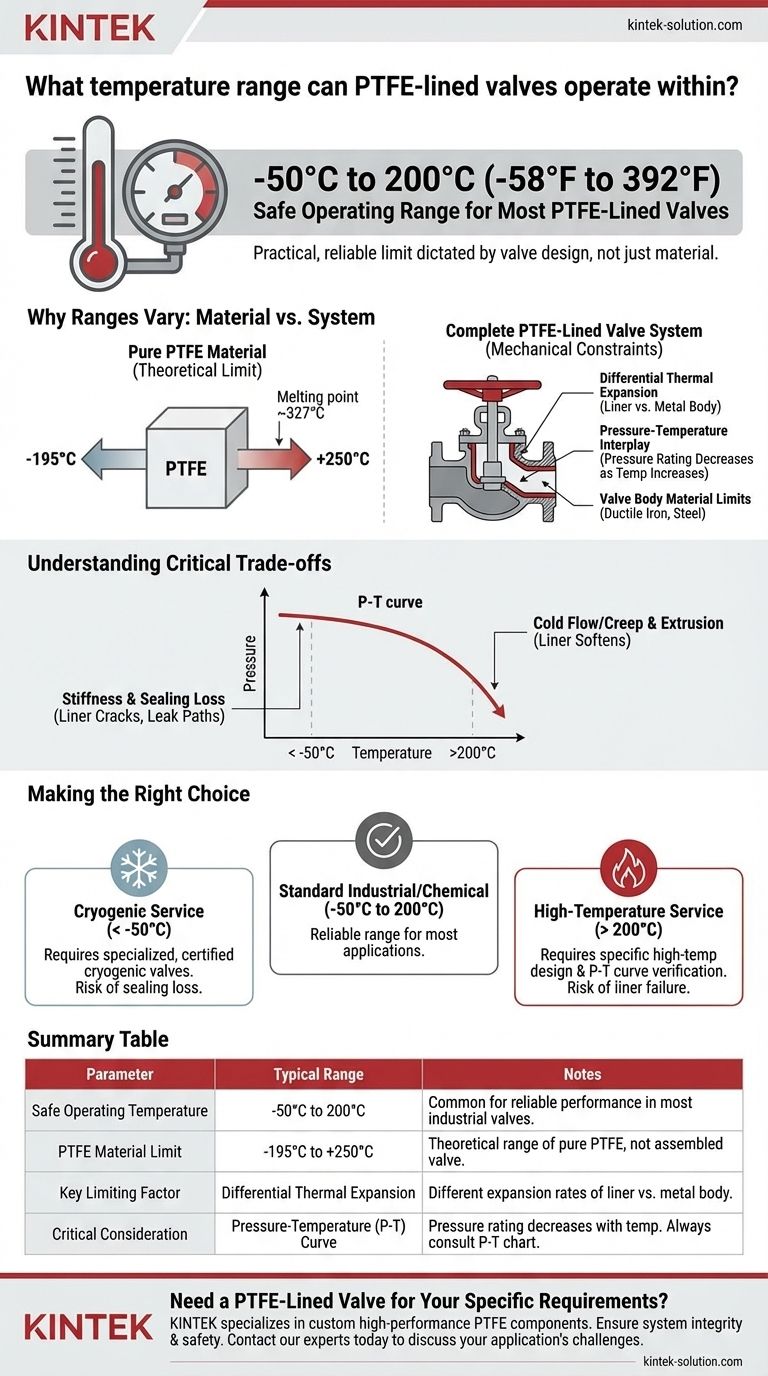

In practice, the reliable operating temperature for most PTFE-lined valves is between -50°C and 200°C (-58°F to 392°F). While the PTFE material itself can withstand a wider range, the valve's mechanical design and other components typically constrain its effective, safe working limits.

The specified temperature range for a PTFE-lined valve is a property of the entire system, not just the PTFE liner. The interaction between the liner, the valve body, and operating pressure dictates the true operational limits, which are often more conservative than the material's standalone capabilities.

Why Published Temperature Ranges Vary

When you see different temperature ratings for PTFE-lined valves, it's not a contradiction. It reflects a critical distinction between the properties of the raw material and the performance of the assembled product.

The Limit of Pure PTFE

The raw material, Polytetrafluoroethylene (PTFE), has exceptional thermal stability. Its theoretical working range can be as wide as -195°C to +250°C.

The melting point of PTFE is approximately 327°C, which represents an absolute failure point, not a safe operating temperature.

The Impact of Valve Design and Body Material

A valve is a mechanical system. The PTFE liner must work in concert with a metal body, typically made of ductile iron, carbon steel, or stainless steel.

These metals expand and contract with temperature changes at a different rate than the PTFE liner. This differential movement is the primary factor that limits the valve's true operating range.

The Interplay of Pressure and Temperature

A valve’s pressure rating is not static; it decreases as temperature increases. As the PTFE liner softens at higher temperatures, its ability to withstand high pressure is reduced.

Always consult a valve’s specific Pressure-Temperature (P-T) curve. A valve rated for 16 bar at ambient temperature may only be rated for 10 bar at 200°C.

Understanding the Critical Trade-offs

Operating a PTFE-lined valve near or beyond its specified limits introduces significant risks to both performance and safety. Understanding these trade-offs is essential for reliable system design.

Risks of Exceeding High-Temperature Limits

As temperatures rise toward 200°C and beyond, the PTFE liner begins to soften. This can lead to two primary failure modes.

First is "cold flow," or creep, where the liner deforms permanently under pressure, compromising the seal. Second is extrusion, where the softened liner is forced into small gaps, causing irreversible damage. This results in leakage and eventual valve failure.

Challenges at Cryogenic Temperatures

At very low temperatures (typically below -50°C), PTFE becomes progressively stiffer and less flexible. While some specialized designs can operate down to -195°C, standard valves are not suitable for this.

The primary risk is a loss of sealing. As the metal body contracts, the now-rigid liner may not be able to conform to the new shape, creating leak paths. In extreme cases, thermal shock or mechanical stress can even cause the liner to crack.

Making the Right Choice for Your Application

To select the correct valve, you must match the valve's specified system capabilities to your process conditions, not the theoretical limits of the PTFE material.

- If your primary focus is standard industrial or chemical processing: Rely on the common range of -50°C to 200°C as your safe and effective operating window.

- If your primary focus is high-temperature service (above 200°C): You must select a valve specifically designed for high-temperature use and verify its P-T curve with the manufacturer.

- If your primary focus is cryogenic service (below -50°C): Only use valves explicitly designated and certified for cryogenic applications to ensure sealing integrity and material stability.

Ultimately, always treat the manufacturer's technical datasheet as the definitive source of truth for any specific valve.

Summary Table:

| Parameter | Typical Range | Notes |

|---|---|---|

| Safe Operating Temperature | -50°C to 200°C | Common range for reliable performance in most industrial valves. |

| PTFE Material Limit | -195°C to +250°C | Theoretical range of pure PTFE, not the assembled valve. |

| Key Limiting Factor | Differential Thermal Expansion | Different expansion rates of PTFE liner vs. metal body dictate the true range. |

| Critical Consideration | Pressure-Temperature (P-T) Curve | Pressure rating decreases as temperature increases. Always consult the manufacturer's P-T chart. |

Need a PTFE-Lined Valve for Your Specific Temperature and Pressure Requirements?

At KINTEK, we specialize in the custom fabrication of high-performance PTFE components, including seals, liners, and labware. Our expertise is crucial for applications in the semiconductor, medical, laboratory, and industrial sectors where precise temperature and chemical resistance are non-negotiable.

We understand that off-the-shelf solutions don't always fit. That's why we work with you to design and manufacture PTFE-lined valves and components that meet your exact operational limits, from prototypes to high-volume orders.

Ensure your system's integrity and safety. Contact our experts today to discuss your application's specific temperature and pressure challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining