The fundamental difference in designing grooves for PTFE O-rings versus standard elastomer O-rings comes down to one critical property: PTFE is rigid, not elastic. Unlike rubber, PTFE (Polytetrafluoroethylene) does not stretch and has very poor "memory," meaning groove design must prioritize ease of installation and a much lower, more precise degree of compression.

The core challenge with PTFE O-rings is their lack of elasticity. Your groove design must therefore accommodate an O-ring that cannot be stretched into place and requires a specific, limited compression to form a reliable seal without being permanently deformed.

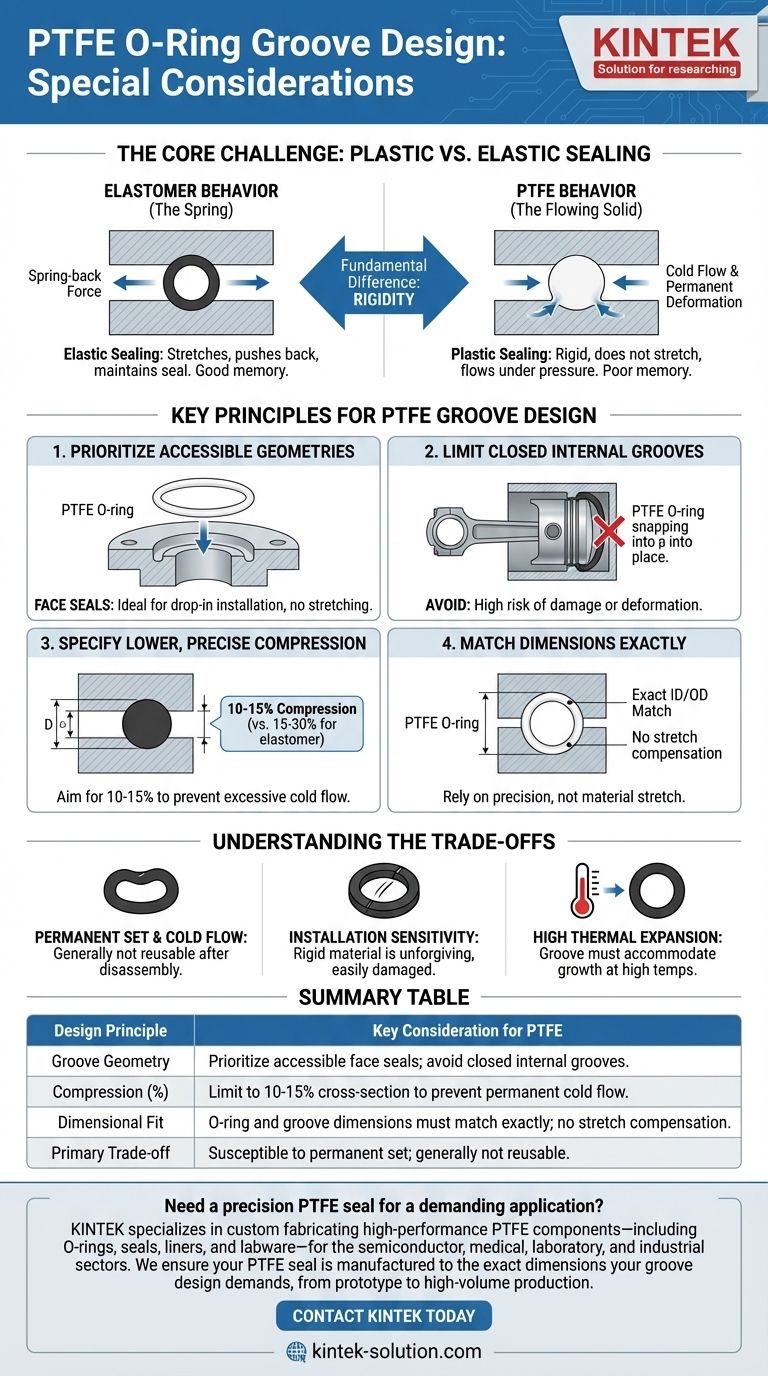

The Core Challenge: Plastic vs. Elastic Sealing

To design an effective groove, you must first understand the material's behavior. An elastomer O-ring acts like a spring, while a PTFE O-ring acts more like a soft, deformable solid.

Elastomer Behavior (The Spring)

A standard rubber O-ring is stretched or compressed during installation. It constantly pushes back against the groove walls, maintaining a seal even with minor imperfections or pressure fluctuations. This is elastic sealing.

PTFE Behavior (The Flowing Solid)

PTFE does not have this "spring-back" quality. When compressed, it tends to "cold flow" or permanently deform rather than rebound. Your design goal is to use system pressure to energize the seal, forcing the PTFE into the clearance gaps. This is closer to plastic sealing.

Key Principles for PTFE O-Ring Groove Design

Because you cannot rely on the material's elasticity, the mechanical design of the groove becomes far more critical for ensuring a leak-proof seal.

Prioritize Accessible Groove Geometries

The single most important consideration is how the O-ring will be installed. Because it cannot be stretched, closed grooves are highly problematic.

Face seals, such as those in flange connections or on covers, are the ideal application. These allow the O-ring to be dropped into place without any stretching or difficult manipulation.

Limit Use in Closed Internal Grooves

Avoid designs where the O-ring must be stretched over a piston and snapped into an internal groove. This process is nearly certain to damage or permanently deform a solid PTFE O-ring, leading to immediate seal failure.

Specify Lower, Precise Compression

While a typical elastomer O-ring may be compressed by 15-30% of its cross-section, PTFE requires a much lighter touch.

Aim for a cross-section compression of 10-15%. Any more risks inducing excessive cold flow, which permanently reduces the O-ring's sealing ability. Any less may not provide enough force for an initial seal.

Match O-Ring and Groove Dimensions Exactly

You cannot rely on material stretch to compensate for minor dimensional variations. The O-ring's inner or outer diameter should correspond exactly to the nominal dimensions of the gland it will sit in.

This precision ensures the O-ring is properly supported and that compression is applied evenly across its cross-section.

Understanding the Trade-offs

Using PTFE provides exceptional chemical and thermal resistance, but this performance comes with significant mechanical limitations that must be respected in the design.

Permanent Set and Cold Flow

The primary trade-off is PTFE's tendency to take a permanent set. If a joint is disassembled, a PTFE O-ring generally cannot be reused. It has conformed to the shape of the groove and lost any ability to re-seal.

Installation Sensitivity

The rigidity of PTFE makes it unforgiving. Forcing an O-ring into a poorly designed or inaccessible groove will likely create a small nick, scratch, or stress point. This tiny area of damage is often the precise location where a leak will begin under pressure.

High Thermal Expansion

PTFE expands and contracts with temperature changes far more than most metals. Your groove design must account for this by providing enough volume to accommodate the O-ring's growth at high temperatures without extruding it.

Making the Right Choice for Your Application

Your design strategy should be dictated by the specific type of seal you are creating.

- If your primary focus is a static face seal: This is the ideal use case. Design a simple rectangular or dovetail groove that allows for drop-in installation and provides 10-15% cross-sectional compression.

- If your primary focus is a dynamic seal: A standard PTFE O-ring is often a poor choice. Consider a spring-energized PTFE seal, which incorporates a metal spring to provide the mechanical "memory" that the PTFE material lacks.

- If your primary focus is retrofitting an existing groove: This is high-risk. Instead of forcing a standard-size PTFE O-ring, leverage the fact that PTFE is easily machined to create a custom-sized O-ring that perfectly matches the existing gland dimensions.

Ultimately, successful PTFE O-ring sealing is achieved by accommodating the material's rigidity in your mechanical design.

Summary Table:

| Design Principle | Key Consideration for PTFE |

|---|---|

| Groove Geometry | Prioritize accessible face seals; avoid closed internal grooves. |

| Compression (%) | Limit to 10-15% cross-section to prevent permanent cold flow. |

| Dimensional Fit | O-ring and groove dimensions must match exactly; no stretch compensation. |

| Primary Trade-off | Susceptible to permanent set; generally not reusable after disassembly. |

Need a precision PTFE seal for a demanding application?

Designing a reliable seal with rigid PTFE requires expert knowledge and precision manufacturing. KINTEK specializes in custom fabricating high-performance PTFE components—including O-rings, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We ensure your PTFE seal is manufactured to the exact dimensions your groove design demands, from prototype to high-volume production.

Contact KINTEK today to discuss your specific requirements and get a quote for a sealing solution built for performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining