Before specifying Polytetrafluoroethylene (PTFE) for any application, you must move beyond its general reputation and critically evaluate four key factors: its chemical compatibility with your specific media, its performance within your required temperature range, its ability to withstand mechanical loads without deforming, and whether a "filled" grade is necessary to enhance its inherent properties. While PTFE is an exceptionally versatile material, its unique characteristics, particularly its softness and high rate of thermal expansion, demand careful design consideration to prevent component failure.

PTFE's exceptional chemical inertness and low-friction surface are offset by its relatively low mechanical strength and significant thermal expansion. The key to successful specification is not just choosing PTFE, but selecting the correct grade—virgin or filled—and designing the component to accommodate its specific behaviors under your application's operational load and temperature.

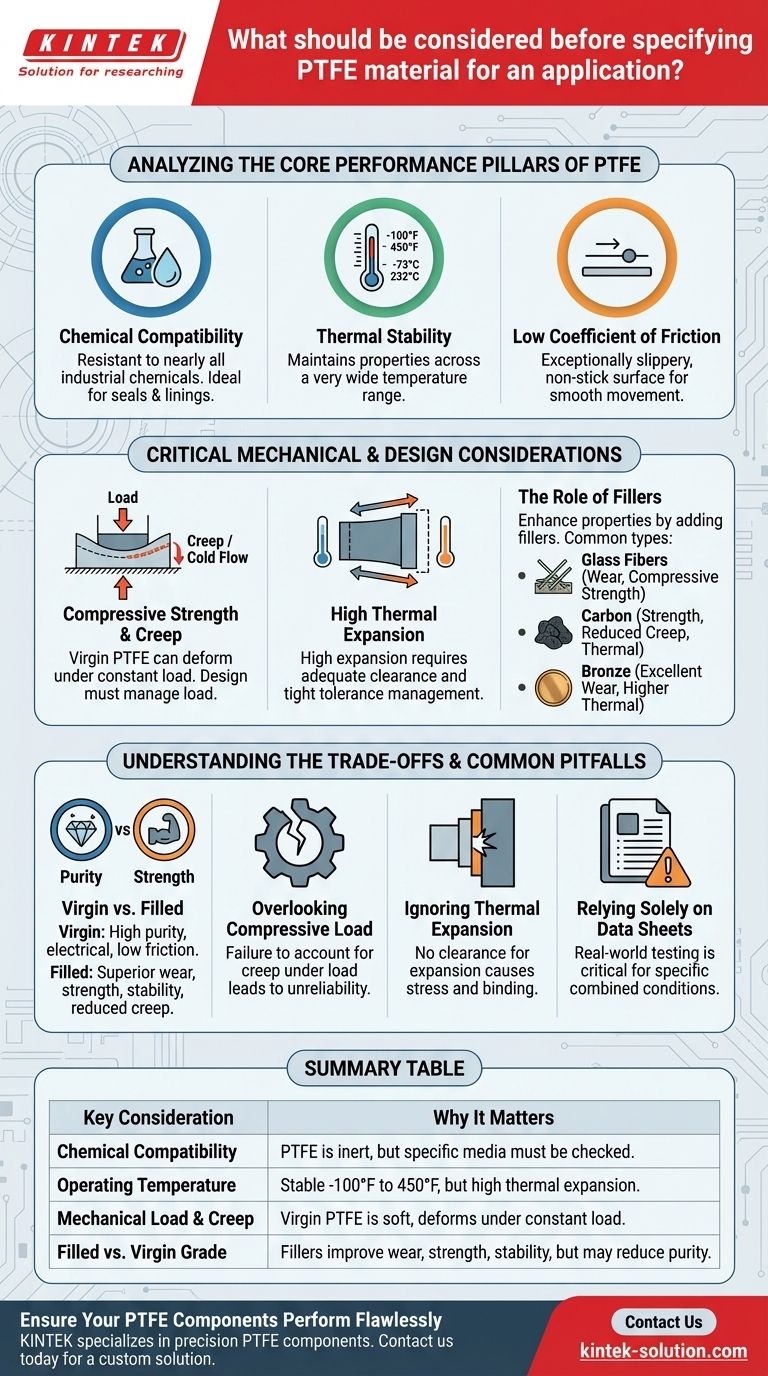

Analyzing the Core Performance Pillars of PTFE

To properly specify PTFE, you must first understand its foundational strengths. These inherent properties are what make it a candidate material in the first place, but they each come with context that is critical for design.

Chemical Compatibility and Inertness

PTFE is famously resistant to nearly all industrial chemicals, including aggressive acids, solvents, and alkalis. This makes it an ideal choice for seals, gaskets, and linings in chemically harsh environments. Its molecular structure is extremely stable, preventing it from reacting with or degrading in the presence of corrosive substances.

Thermal Stability and Operating Range

The material maintains its properties across a very wide temperature range, typically from -100°F up to 450°F (-73°C to 232°C), with some grades rated for short-term exposure up to 500°F (260°C). This excellent thermal stability allows it to be used in both cryogenic and high-heat applications where other plastics would fail.

Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, giving it an exceptionally slippery, non-stick surface. This property is invaluable for applications requiring smooth movement with minimal resistance, such as in bearings, slide plates, and non-stick coatings.

Critical Mechanical and Design Considerations

While its core properties are impressive, PTFE's mechanical behavior is where specifications most often go wrong. A design that fails to account for its limitations will not perform reliably, regardless of its chemical or thermal resistance.

Compressive Strength and Creep

Unfilled, or "virgin," PTFE is a relatively soft material. When subjected to a constant compressive load, especially at elevated temperatures, it can slowly deform over time. This phenomenon, known as creep or cold flow, is a critical design consideration for sealing applications. The dimensions of a gasket groove, for example, must be engineered to provide the right amount of compression without overloading the material.

High Thermal Expansion

PTFE expands and contracts with temperature changes more than most other engineering materials. This high coefficient of thermal expansion must be accounted for in your design tolerances. A part designed for a tight fit at room temperature may bind, seize, or cause component failure when operating temperatures rise.

The Role of Fillers

To counteract the mechanical limitations of virgin PTFE, various fillers are often added to create a composite material. The choice of filler is directly tied to the performance you need to improve.

- Glass fibers increase wear resistance and compressive strength.

- Carbon enhances strength, reduces creep, and improves thermal conductivity.

- Bronze provides excellent wear resistance and higher thermal conductivity.

Machinability and Tolerances

PTFE is an inexpensive and highly machinable plastic, allowing for complex geometries to be produced via CNC machining. However, its softness and thermal expansion require specialized machining techniques to hold tight tolerances and achieve a precise surface finish.

Understanding the Trade-offs and Common Pitfalls

Building trust in your design requires acknowledging the material's limitations and avoiding common mistakes. The most successful applications of PTFE are those where the designer understood these trade-offs from the start.

Virgin PTFE vs. Filled Grades

The primary trade-off is between purity and mechanical performance. Virgin PTFE offers the highest chemical purity, best electrical insulation, and lowest coefficient of friction. Filled grades offer superior wear resistance, reduced creep, and greater dimensional stability, but the filler may compromise chemical inertness or electrical properties.

Overlooking Compressive Load

A frequent mistake is using PTFE in a high-load mechanical application without accounting for its tendency to creep. It is not a suitable replacement for high-strength plastics like PEEK or metals in structural roles unless the design specifically manages the load.

Ignoring Thermal Expansion in Design

Failing to leave adequate clearance for thermal expansion is a guaranteed path to failure. Mating parts, especially those with different materials, must be designed with the full operational temperature range in mind to prevent stress and binding.

Relying Solely on Data Sheets

Manufacturer specification sheets provide essential baseline data. However, this information should be considered informational and must be cross-checked for suitability in your specific application. Real-world conditions involving combined pressure, temperature, and chemical exposure often require application-specific testing to ensure reliability.

Making the Right Choice for Your Application

Use your core engineering goals to guide your material selection process.

- If your primary focus is chemical purity or electrical insulation: Virgin PTFE is almost always the correct choice due to its absolute inertness and lack of potentially reactive or conductive fillers.

- If your primary focus is wear resistance and dimensional stability: A filled PTFE, such as a glass- or carbon-filled grade, is necessary to handle mechanical stress and minimize changes due to temperature.

- If your primary focus is low friction in a static or low-load seal: Virgin PTFE is often sufficient, but you must carefully engineer the design to account for potential creep and thermal expansion.

- If you are operating under high pressure and temperature: You must specify a filled compound engineered to resist creep and verify its performance data against your exact operational conditions.

Ultimately, successful PTFE specification comes from treating it not as a generic plastic, but as a specialized material whose performance is dictated by its specific grade and your design.

Summary Table:

| Key Consideration | Why It Matters |

|---|---|

| Chemical Compatibility | PTFE is inert to most chemicals, but specific media must be checked. |

| Operating Temperature | Stable from -100°F to 450°F, but thermal expansion is high. |

| Mechanical Load & Creep | Virgin PTFE is soft and can deform under constant load (cold flow). |

| Filled vs. Virgin Grade | Fillers (glass, carbon, bronze) improve wear, strength, and stability, but may reduce purity. |

Ensure Your PTFE Components Perform Flawlessly

Specifying the right PTFE grade and design is critical for reliability in demanding environments. KINTEK specializes in manufacturing precision PTFE components—from seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors.

We don't just supply parts; we provide solutions. Our expertise ensures your PTFE components are correctly specified and fabricated to handle your exact chemical, thermal, and mechanical requirements, whether you need prototypes or high-volume production.

Contact us today to discuss your application and receive a custom solution that guarantees performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability