In selecting PTFE packing, chemical exposure is the primary gatekeeper for material suitability. While Polytetrafluoroethylene (PTFE) is renowned for its broad chemical resistance, it is not universally inert. A thorough evaluation of the specific chemicals and their concentrations is a non-negotiable first step to prevent material degradation and seal failure.

The core challenge is not simply choosing a "chemical-resistant" material, but matching a specific PTFE formulation to the precise chemical environment, while simultaneously balancing other critical operational demands like temperature, pressure, and mechanical stress.

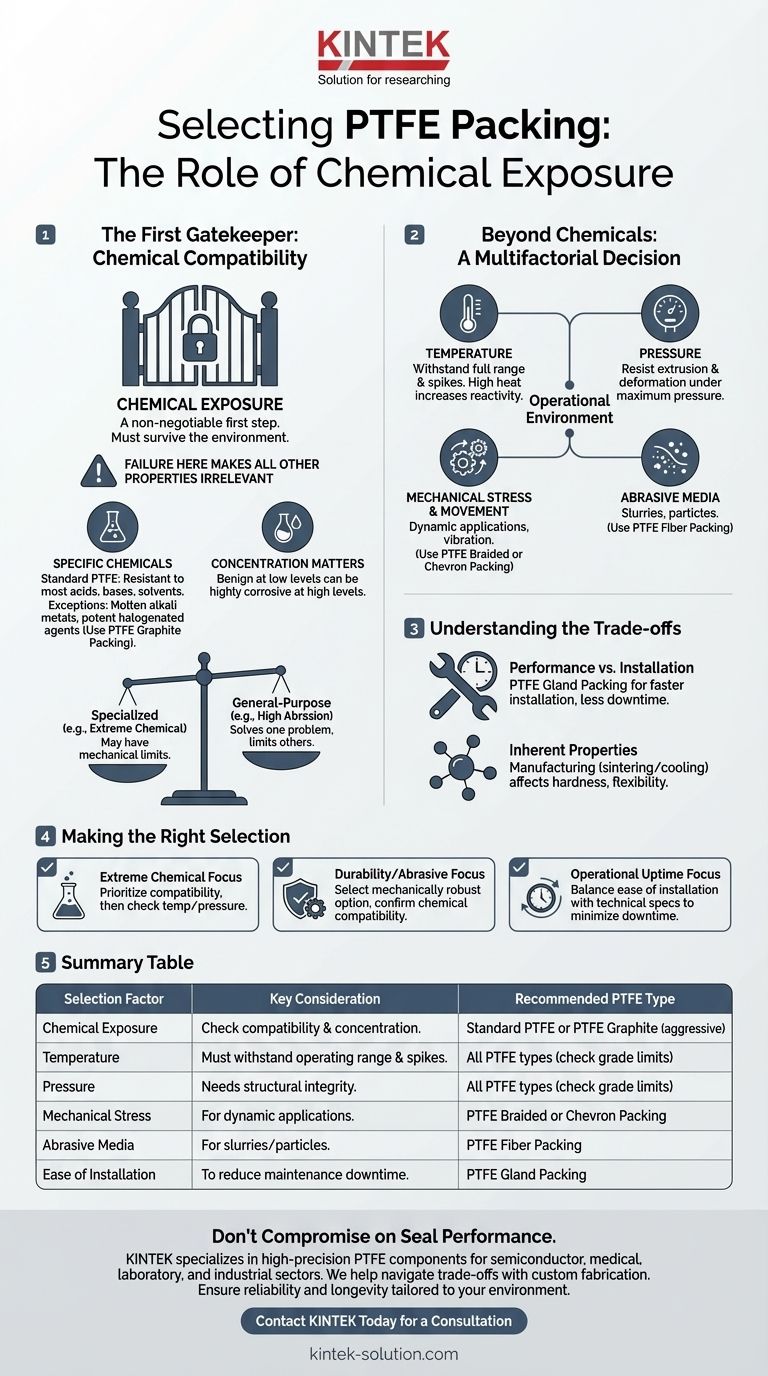

Why Chemical Compatibility is the First Gatekeeper

Before considering any other factor, you must confirm that the packing material can survive its chemical environment. A failure here makes all other properties irrelevant.

PTFE's Baseline Chemical Resistance

Standard PTFE is resistant to a vast range of chemicals, including most acids, bases, solvents, and corrosive agents. This is why it is a go-to choice for a wide array of industrial applications.

Identifying the Exceptions

Despite its robust nature, certain aggressive substances can attack PTFE. These often include molten alkali metals and potent halogenated agents.

For these extreme cases, a standard PTFE packing is insufficient. You must opt for a specialized formulation, such as PTFE graphite packing, which is engineered to handle these specific aggressive media.

The Critical Role of Concentration

The type of chemical is only half the story. The concentration of that chemical is equally important. A substance that is benign at low concentrations can become highly corrosive and damaging to the packing material at higher levels.

Beyond Chemicals: A Multifactorial Decision

Once chemical compatibility is confirmed, you must evaluate the packing against the full scope of its operational environment. A packing that is chemically sound can still fail if it cannot handle the physical demands of the application.

Operating Temperature

The packing must be ableto withstand the full temperature range of the application, including both normal operating temperatures and any potential spikes or extremes. High temperatures can degrade the packing material and may also increase the reactivity of the chemicals it is exposed to.

Pressure Conditions

High-pressure environments place immense stress on the packing's ability to create and maintain a seal. The selected packing must have the structural integrity to resist extrusion and deformation under the application's maximum pressure.

Mechanical Stress and Movement

The physical forces on the packing are a crucial consideration. For dynamic applications involving movement, vibration, or rotation, a standard packing may wear out quickly.

In these cases, materials like PTFE braided packing or PTFE chevron packing are specifically designed to offer superior durability and a longer service life under constant mechanical stress.

Abrasive Media

Environmental conditions can introduce other challenges. If the process fluid contains abrasive particles or slurries, you need a packing designed for high wear resistance.

PTFE fiber packing, for example, is often chosen for its enhanced ability to handle abrasive media without premature failure.

Understanding the Trade-offs

There is no single "best" PTFE packing for every situation. Selecting the right one involves understanding and balancing competing properties.

Specialized vs. General-Purpose

A packing engineered for extreme chemical resistance might have different mechanical properties than one designed for high abrasion. Opting for a specialized material solves one problem but may introduce limitations in other performance areas.

Performance vs. Ease of Installation

Some packing types, such as PTFE gland packing, are specifically designed for faster and easier installation. This can significantly reduce downtime during maintenance. This operational efficiency may be a more valuable trade-off than selecting a marginally higher-performing but more complex material to install.

Inherent Material Properties

Even the manufacturing process, such as the sintering and cooling rate, dictates the final physical properties of the PTFE compound. This can affect everything from hardness to flexibility, creating inherent trade-offs in the raw material itself.

Making the Right Selection for Your Application

Your final choice must be a holistic one, based on a clear understanding of your primary operational goal.

- If your primary focus is extreme chemical resistance: Prioritize a thorough chemical compatibility check and specify a specialized formulation if needed, ensuring it still meets baseline temperature and pressure requirements.

- If your primary focus is durability in a dynamic or abrasive environment: Select a mechanically robust option like braided or fiber packing, after first confirming it is fully compatible with the chemical media.

- If your primary focus is balancing performance with operational uptime: Consider factors like ease of installation alongside the core technical specifications to minimize costly downtime during maintenance cycles.

Ultimately, a successful outcome depends on a comprehensive analysis of the entire operational system, not just a single variable.

Summary Table:

| Selection Factor | Key Consideration | Recommended PTFE Type |

|---|---|---|

| Chemical Exposure | Check compatibility with specific chemicals & concentrations. | Standard PTFE or PTFE Graphite (for aggressive agents) |

| Temperature | Must withstand operating temperature & spikes. | All PTFE types, check grade limits |

| Pressure | Needs structural integrity to resist extrusion. | All PTFE types, check grade limits |

| Mechanical Stress | For dynamic applications with movement/vibration. | PTFE Braided or Chevron Packing |

| Abrasive Media | For slurries or fluids with particles. | PTFE Fiber Packing |

| Ease of Installation | To reduce maintenance downtime. | PTFE Gland Packing |

Don't Compromise on Seal Performance

Selecting the right PTFE packing is a complex balance of chemical resistance, temperature, pressure, and mechanical demands. KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We provide the expertise to help you navigate these trade-offs, offering custom fabrication from prototypes to high-volume orders. Ensure your application's reliability and longevity with a packing solution tailored to your exact operational environment.

Contact KINTEB today for a consultation and let our experts help you specify the perfect PTFE packing.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What chemical resistance properties do expanded PTFE gaskets have? Achieve Universal Sealing for Aggressive Chemicals

- What are some common applications for PTFE rotary seals? Sealing Solutions for Extreme Environments

- What is the advantage of using spread/flat glass reinforcement in PTFE laminates? Achieve Superior Signal Integrity for High-Frequency Electronics

- What makes PTFE an ideal sealing material overall? Superior Performance in Extreme Conditions

- What are the advantages of using PTFE piston seals in high duty cycle linear actuators? Achieve Smooth, Long-Lasting Performance

- What are some common industries and applications for PTFE/Teflon machined parts? Solve Harsh Environment Challenges

- What industries commonly use PTFE components? Critical Solutions for Extreme Environments

- How do PTFE and NBR oil seals compare in terms of friction and wear? Choose the Right Seal for Your Application