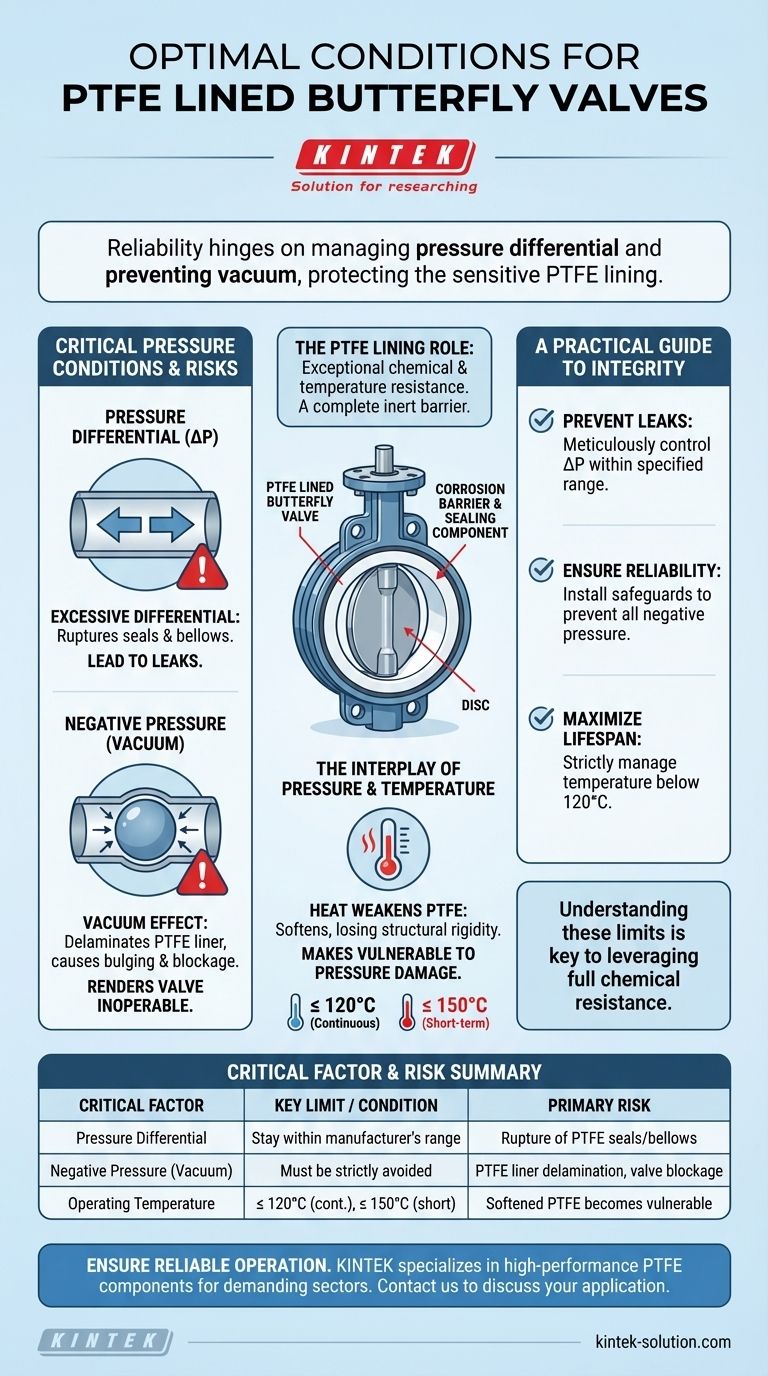

To ensure reliability, the two most critical pressure conditions for a PTFE lined butterfly valve are controlling the pressure differential across the valve and strictly avoiding any negative pressure (vacuum) within the pipeline. Exceeding the allowable pressure difference can rupture sealing components, while negative pressure can cause the PTFE liner itself to detach and obstruct the valve.

The operational integrity of a PTFE lined butterfly valve is not determined by system pressure alone. True reliability hinges on managing the pressure differential across the valve and preventing vacuum conditions, as both can cause physical damage to the sensitive PTFE lining.

The Role of the PTFE Lining

A PTFE lined butterfly valve is chosen for one primary reason: its exceptional resistance to corrosive chemicals and extreme temperatures. The PTFE (polytetrafluoroethylene) layer is the component that delivers this performance.

The Heart of Corrosion Resistance

The PTFE lining acts as a complete, inert barrier between the process medium (like strong acids or alkalis) and the metal body of the valve. This protects the structural components from chemical attack.

The Mechanism of Sealing

Beyond corrosion protection, the PTFE material is also integral to the valve's sealing capability. It forms the seat that the valve disc closes against, creating a tight shutoff to prevent leaks.

Critical Pressure Conditions and Their Impact

Failure to manage specific pressure scenarios is the most common cause of premature valve failure. These are distinct from the overall pressure rating of the system.

The Danger of Excessive Pressure Differential

The pressure difference (or differential pressure) is the difference in pressure between the inlet and outlet of the valve.

When this difference exceeds the valve's design limits, it can place immense stress on the sealing components. For valves that use a PTFE bellows for stem sealing, this excessive force can cause the bellows to rupture, leading to immediate leakage.

The Hidden Threat of Negative Pressure (Vacuum)

Negative pressure is a condition where the pressure inside the pipeline drops below the atmospheric pressure outside.

This creates a vacuum effect that can literally suck the PTFE lining away from the inner wall of the valve body. This delamination causes the liner to bulge or buckle, physically blocking the disc from opening or closing properly and rendering the valve inoperable.

The Critical Interplay of Pressure and Temperature

Pressure and temperature are not independent variables; they work together to affect the integrity of the PTFE lining.

How High Temperatures Weaken the Lining

PTFE is a type of polymer, and like most plastics, it softens with heat. For a PTFE lined valve, the medium temperature should not exceed 150°C even for short periods.

For long-term, continuous operation, the temperature should be controlled at or below 120°C.

Softened PTFE Magnifies Pressure Problems

When the PTFE lining softens due to excessive heat, it loses its structural rigidity. A weakened liner is far more susceptible to being deformed by pressure differentials or being pulled away from the valve body by negative pressure. This is why adhering to temperature limits is just as crucial as managing pressure.

Understanding the Trade-offs

The high performance of a PTFE lined valve comes with distinct operational boundaries. Understanding these limitations is key to avoiding failure.

Performance vs. Operating Limits

The valve provides superior chemical resistance that most metal valves cannot match. However, this benefit is exchanged for a lower tolerance for pressure spikes, vacuum conditions, and high temperatures compared to a solid metal alloy valve.

Cost vs. Longevity

Ignoring these pressure and temperature limits in an attempt to push throughput will lead to premature and often catastrophic valve failure. The cost of unplanned downtime and valve replacement almost always outweighs the perceived benefit of operating outside the specified design window.

A Practical Guide to Valve Integrity

Use these guidelines to ensure the reliability and longevity of your PTFE lined butterfly valves.

- If your primary focus is preventing leaks and ensuring shutoff: Meticulously control the pressure differential to stay well within the manufacturer's specified range to protect the valve's seat and seals.

- If your primary focus is operational reliability: Install safeguards and monitor your process to absolutely prevent negative pressure conditions, which can cause immediate mechanical failure.

- If your primary focus is maximizing valve lifespan: Strictly manage the process temperature to remain below 120°C for continuous service, as heat fundamentally weakens the PTFE lining and makes it vulnerable to pressure-related damage.

Understanding these interconnected limits is the key to leveraging the full chemical resistance and performance of your valve.

Summary Table:

| Critical Factor | Key Limit / Condition | Primary Risk |

|---|---|---|

| Pressure Differential | Stay within manufacturer's specified range | Rupture of PTFE seals/bellows, leading to leaks |

| Negative Pressure (Vacuum) | Must be strictly avoided | PTFE liner delamination, causing valve blockage |

| Operating Temperature | ≤ 120°C (continuous), ≤ 150°C (short-term) | Softened PTFE becomes vulnerable to pressure damage |

Ensure your PTFE lined valves operate reliably under demanding conditions.

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including custom seals, liners, and labware. Our expertise ensures your valves and systems for the semiconductor, medical, laboratory, and industrial sectors are built to handle specific pressure and temperature requirements, maximizing uptime and longevity.

Contact us today to discuss your application needs—from prototypes to high-volume orders—and let our solutions enhance your process integrity. #ContactForm

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems