In short, the primary post-processing techniques for PTFE parts are deburring and polishing. These methods refine the components after the initial machining phase, removing rough edges and creating the specific surface finish required for the part's final application, ensuring it meets both quality and performance standards.

Post-processing is not an optional add-on; it is a critical manufacturing stage that transforms a roughly shaped PTFE component into a precise, functional part ready for its demanding role in industrial or electrical applications.

Why Post-Processing is Non-Negotiable for PTFE

Before a PTFE part can be post-processed, it must first be created. Understanding this initial step clarifies why subsequent refinement is so essential.

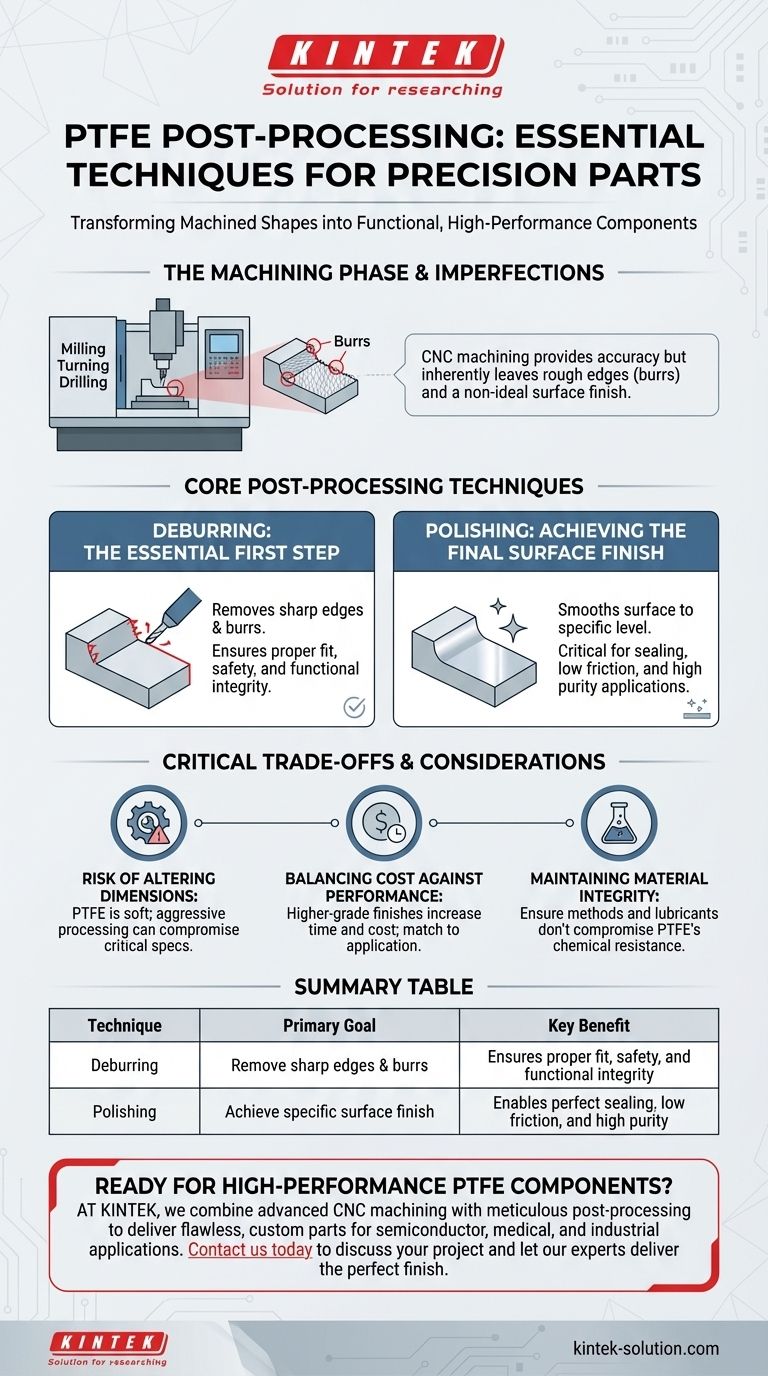

The Initial Machining Phase

PTFE components are formed using precision CNC (Computer Numerical Control) machining. This automated process provides high accuracy and repeatability, which is crucial for complex designs.

The main methods include:

- CNC Milling: Used to create complex shapes, cavities, and intricate patterns.

- CNC Turning: Ideal for producing cylindrical parts like seals, rings, and shafts.

- Drilling and Tapping: Employed to create precise holes and threads within the component.

The Inevitable Result: Imperfections

Even with the most advanced CNC equipment, the machining process inherently leaves behind minor imperfections. These include rough edges, known as burrs, and a surface texture that may not be suitable for the final application.

Core Post-Processing Techniques Explained

Once the part is machined, post-processing addresses these imperfections to meet final specifications.

Deburring: The Essential First Step

Deburring is the process of removing the sharp, rough edges and burrs left behind by milling, turning, or drilling. This is the most fundamental post-processing step for any machined PTFE part.

This is done to ensure proper fit with other components, improve safety for handlers, and guarantee functional integrity, as loose burrs could break off and contaminate a system.

Polishing: Achieving the Final Surface Finish

Polishing goes beyond simply removing rough edges. It is a more refined process intended to smooth the entire surface of the PTFE part to a specific level of finish.

A polished surface is critical for applications requiring a perfect seal, low friction, or high purity. For example, PTFE gaskets used in electrical transformers must have a smooth, uniform surface to prevent leaks and ensure longevity.

Understanding the Trade-offs and Considerations

Choosing the right post-processing technique requires balancing performance needs with practical limitations. PTFE's unique properties introduce specific challenges.

Risk of Altering Dimensions

PTFE is a relatively soft material. Overly aggressive deburring or polishing can accidentally remove too much material, altering the part's critical dimensions and rendering it useless. The process must be carefully controlled.

Balancing Cost Against Performance

Extensive post-processing, especially to achieve a mirror-like polish, adds significant time and cost to production. It is crucial to determine if the application truly requires such a high-grade finish or if a standard deburred surface is sufficient.

Maintaining Material Integrity

The methods used for post-processing must not compromise PTFE's renowned properties, such as its chemical resistance and thermal stability. Any lubricants, polishing compounds, or handling methods must be compatible with the material to avoid contamination or damage.

Matching the Process to Your Application

Your final decision should be driven entirely by the part's intended function.

- If your primary focus is functional fit and safety: Standard deburring is the essential, non-negotiable minimum to ensure parts assemble correctly and are safe to handle.

- If your primary focus is high-performance sealing or low friction: A carefully controlled polishing process is necessary to create the smooth surface required for effective sealing and minimal wear.

- If your primary focus is producing intricate, high-precision parts: Rely on advanced CNC machining to minimize initial imperfections, followed by meticulous, targeted deburring on critical edges.

Ultimately, proper post-processing is what elevates a machined PTFE shape into a reliable, high-performance component.

Summary Table:

| Technique | Primary Goal | Key Benefit |

|---|---|---|

| Deburring | Remove sharp edges & burrs | Ensures proper fit, safety, and functional integrity |

| Polishing | Achieve specific surface finish | Enables perfect sealing, low friction, and high purity |

Ready to ensure your PTFE components meet the highest standards of precision and performance?

At KINTEK, we understand that the final finish is critical to your application's success. Our expertise in precision post-processing—from essential deburring to high-grade polishing—guarantees your PTFE seals, liners, and labware perform flawlessly in demanding semiconductor, medical, and industrial environments.

We combine advanced CNC machining with meticulous post-processing to deliver custom parts, from prototypes to high-volume orders, that are built to last.

Contact us today to discuss your project requirements and let our experts deliver the perfect finish for your critical components.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application