In short, PTFE-free bushings provide value by offering an environmentally friendly and often more cost-effective alternative to traditional PTFE, particularly for applications where concerns over PFAS chemicals or specific mechanical properties like structural rigidity are paramount. They achieve this while still delivering reliable, high-performance, and durable solutions for a wide range of industrial uses.

The decision to use a PTFE-free bushing is not about finding a universally "better" material, but about making a targeted trade-off. You are typically prioritizing environmental compliance, cost, or specific mechanical strengths over the unique low-friction and broad chemical resistance characteristics of PTFE.

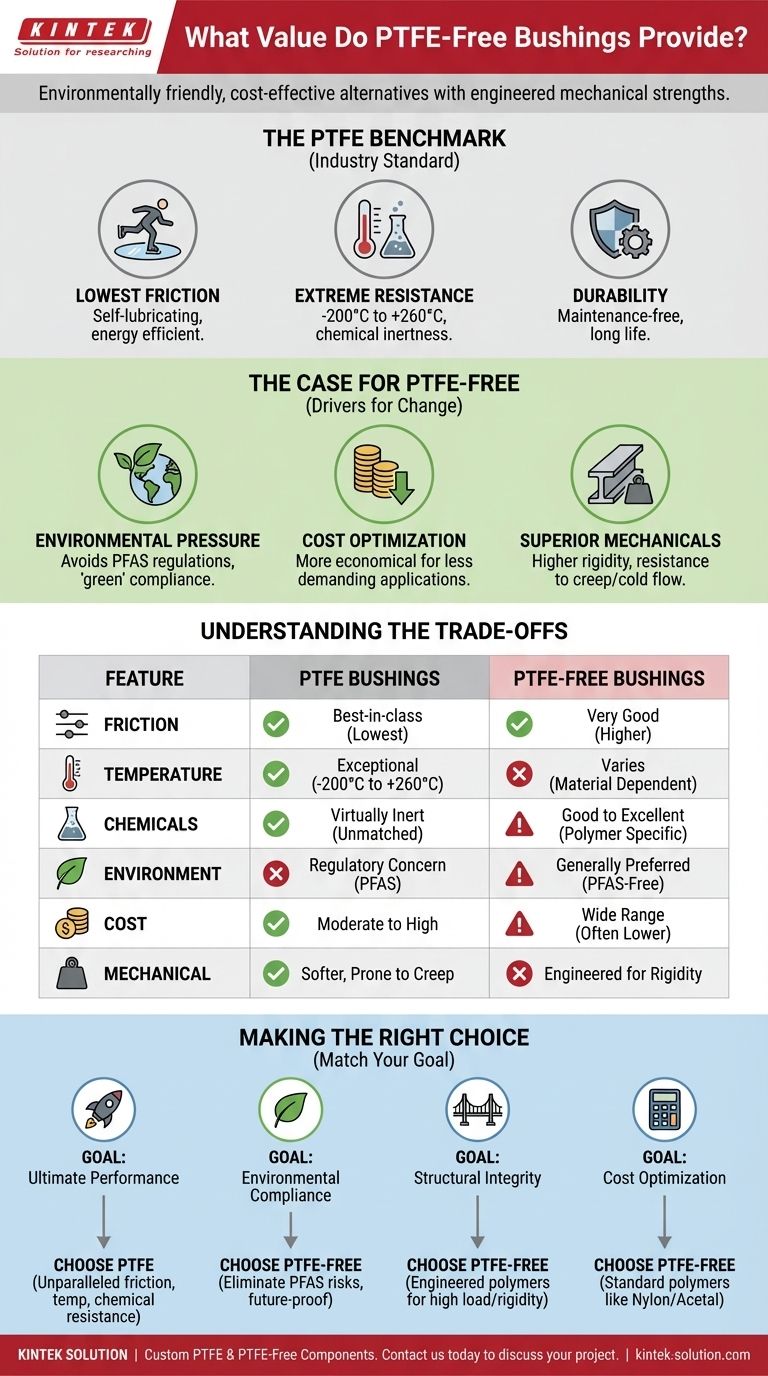

Understanding the PTFE Benchmark

To grasp the value of PTFE-free options, we must first understand why Polytetrafluoroethylene (PTFE) became an industry standard for bushings. Its properties set a high benchmark for performance.

The Lowest Coefficient of Friction

PTFE has the lowest coefficient of friction of any known solid material. This creates a self-lubricating surface that is exceptionally slick.

This property is critical for reducing energy consumption and minimizing heat buildup, especially in high-speed or high-load scenarios. The result is a more efficient system that requires little to no external lubrication.

Extreme Temperature and Chemical Resistance

PTFE bushings operate reliably across an exceptionally wide temperature range, often cited from -200°C to +260°C (-328°F to +500°F).

They are also virtually inert, offering outstanding resistance to almost all industrial chemicals, solvents, and moisture. This makes them ideal for harsh operating environments where other materials would quickly degrade.

Durability and Maintenance-Free Operation

The combination of self-lubrication and high resistance means PTFE bushings offer a long, maintenance-free service life.

Their non-stick surface also prevents the buildup of contaminants, which simplifies cleaning and ensures consistent performance over time.

The Case for PTFE-Free Alternatives

If PTFE is so effective, the compelling reason to seek an alternative is to address its specific limitations. The move toward "PTFE-free" is driven by distinct regulatory, cost, and mechanical considerations.

Environmental and Regulatory Pressure

The most significant driver is environmental regulation. PTFE is part of a larger group of chemicals known as PFAS (per- and polyfluoroalkyl substances), which face increasing scrutiny and restrictions globally due to their persistence in the environment.

For companies aiming to future-proof their products against evolving regulations or meet specific "green" initiatives, choosing a PTFE-free bushing is a direct and effective strategy.

Optimizing for Cost

While PTFE offers an excellent price-to-performance ratio, it is not always the cheapest material. In applications with less demanding temperature or chemical requirements, a simpler and less expensive polymer can provide sufficient performance.

PTFE-free bushings, made from materials like polyamide (Nylon), acetal, or PEEK, can offer a more cost-effective solution when the extreme properties of PTFE are unnecessary.

Superior Mechanical Properties in Specific Cases

PTFE is a relatively soft material and can be susceptible to "creep" or cold flow—a slow deformation under sustained load.

Certain engineered PTFE-free polymers can offer superior hardness, structural rigidity, and wear resistance under high static loads. In these applications, a PTFE-free bushing isn't just an alternative; it's a mechanically superior choice.

Understanding the Trade-offs

Choosing between PTFE and PTFE-free is an engineering decision that requires balancing competing priorities. There is no single best answer for every situation.

| Feature | PTFE Bushings | PTFE-Free Bushings | The Bottom Line |

|---|---|---|---|

| Friction | Best-in-class. Lowest coefficient of any solid. | Very good, but higher than PTFE. Still provides excellent low-friction performance. | If absolute minimum friction is your primary goal, PTFE is unmatched. |

| Temperature | Exceptional. Very wide operating range (-200°C to +260°C). | Varies by material. Some (like PEEK) have high ranges; others are more limited. | PTFE offers the most reliable performance at extreme temperatures. |

| Chemicals | Virtually inert. Unmatched resistance to almost all chemicals. | Good to excellent. Depends entirely on the specific polymer used. | For aggressive chemical environments, PTFE remains the safest choice. |

| Environment | Regulatory concern. As a PFAS, its use is increasingly scrutinized. | Generally preferred. Avoids PFAS-related compliance issues. | If environmental compliance is a key driver, PTFE-free is the strategic choice. |

| Cost | Moderate to high. Excellent performance for the price. | Wide range. Can be significantly cheaper or more expensive than PTFE. | PTFE-free options provide more flexibility to align cost with performance needs. |

| Mechanical | Softer. Can be prone to creep under high static loads. | Varies. Can be engineered for high rigidity and load-bearing strength. | For high-load structural applications, a specific PTFE-free polymer is often better. |

Making the Right Choice for Your Goal

Your application's primary objective should guide your material selection.

- If your primary focus is ultimate performance: Choose PTFE for its unparalleled combination of low friction, temperature range, and chemical resistance.

- If your primary focus is environmental compliance and future-proofing: Choose a PTFE-free alternative to eliminate PFAS-related risks and meet green manufacturing standards.

- If your primary focus is structural integrity under high load: Investigate specific high-strength, PTFE-free engineered polymers that offer better rigidity and creep resistance.

- If your primary focus is cost-optimization for a standard application: A common PTFE-free polymer like nylon or acetal will likely provide the most value.

Ultimately, understanding the specific strengths and weaknesses of each option empowers you to select the material that truly solves your engineering challenge.

Summary Table:

| Feature | PTFE Bushings | PTFE-Free Bushings |

|---|---|---|

| Friction | Best-in-class, lowest coefficient | Very good, but higher than PTFE |

| Temperature Range | Exceptional (-200°C to +260°C) | Varies by material (some high, some limited) |

| Chemical Resistance | Virtually inert, unmatched | Good to excellent (depends on polymer) |

| Environmental Impact | PFAS-related regulatory concerns | Generally preferred, avoids PFAS issues |

| Cost | Moderate to high | Wide range, often more cost-effective |

| Mechanical Strength | Softer, prone to creep under load | Can be engineered for high rigidity and strength |

Need High-Performance or Custom PTFE Components?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require PTFE for its unmatched chemical and temperature resistance or are exploring PTFE-free alternatives for environmental or mechanical reasons, our expertise ensures you get the right solution. We offer custom fabrication from prototypes to high-volume orders, tailored to your specific needs.

Contact us today to discuss your project and discover how we can enhance your application's performance and compliance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the standard temperature limits for PTFE Teflon O-rings? Master the -200°C to 250°C Range

- What are the key properties of PTFE industrial coating? Discover Unmatched Performance for Demanding Industries

- What is the PH range and temperature tolerance of pure PTFE gaskets? Master Extreme Chemical and Thermal Sealing

- What are the installation methods for PTFE slide bearings? Bolting, Welding & Mortar Embedment

- What industries commonly use PTFE components? Critical Solutions for Extreme Environments

- How do PTFE ring gaskets benefit piston engines? Enhance Engine Reliability and Longevity

- What are the physical and chemical properties of pure PTFE bushings? Unlock Extreme Chemical & Thermal Resistance

- What are the main benefits of using a Teflon sheet for heat press? Achieve Flawless, Professional Transfers