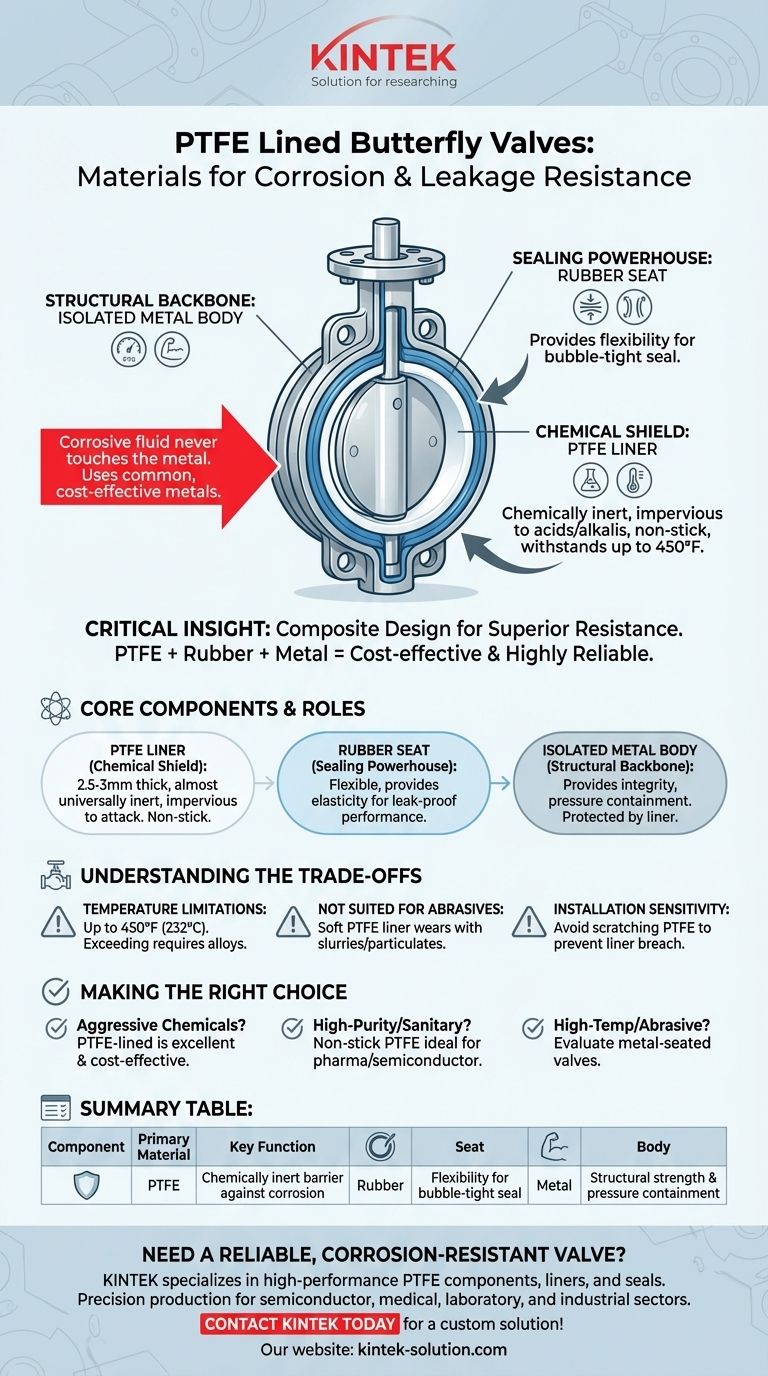

At their core, PTFE-lined butterfly valves achieve superior resistance to corrosion and leakage through a composite design. They use a chemically inert Polytetrafluoroethylene (PTFE) liner to completely isolate the valve's metal body from the fluid, while a flexible rubber seat underneath the liner provides the compressive force needed for a bubble-tight seal.

The critical insight is that these valves don't rely on a single exotic material. Instead, they combine the chemical immunity of PTFE with the flexibility of rubber and the structural strength of conventional metal, creating a cost-effective and highly reliable solution for corrosive applications.

The Core Components and Their Roles

To understand the valve's performance, you must look at how its key materials function as a system. Each component plays a distinct and critical role in preventing failure.

The PTFE Liner: The Chemical Shield

The primary barrier against corrosion is the PTFE (Teflon) liner. This fluoroplastic material, typically 2.5-3mm thick, lines the entire wetted internal surface of the valve.

PTFE is almost universally inert, making it impervious to chemical attack from acids, alkalis, and other aggressive media. It does not oxidize or corrode.

Its excellent non-stick properties and ability to withstand temperatures up to 450°F make it the ideal point of contact for reactive fluids.

The Rubber Seat: The Sealing Powerhouse

Directly beneath the thin PTFE liner sits a rubber seat. While the PTFE provides the chemical resistance, it is a relatively rigid material.

The underlying rubber provides the flexibility and elasticity required for the valve disc to create a tight seal when it closes. This ensures leak-proof performance.

This two-part construction combines the best qualities of both materials: the liner's chemical resistance and the seat's mechanical sealing capability.

The Isolated Metal Body: The Structural Backbone

The body of the valve provides the necessary structural integrity, pressure containment, and connection points for the piping system.

Crucially, in a PTFE-lined design, the corrosive fluid never touches the metal body. The liner acts as a complete, impenetrable barrier.

This allows for the use of more common and cost-effective metals for the valve body without compromising the valve's lifespan in a corrosive service.

Understanding the Trade-offs

While highly effective, this design is not a universal solution. Understanding its limitations is key to proper application and avoiding premature failure.

Temperature Limitations

PTFE has a distinct operational temperature ceiling, typically around 450°F (232°C). For applications exceeding this temperature, alternative high-performance metal alloys must be considered.

Not Suited for Abrasives

The primary strength of this valve is its chemical resistance. The PTFE liner, while durable, is a relatively soft material that can be damaged by abrasive slurries or media with hard particulates, which can wear away the protective lining.

Installation Sensitivity

The integrity of the liner is paramount. Care must be taken during installation to avoid scratching or gouging the PTFE surface, as any breach would expose the underlying metal to the corrosive media and lead to rapid failure.

Making the Right Choice for Your Application

Selecting the correct valve hinges on a clear understanding of your specific operational demands.

- If your primary focus is handling aggressive chemicals: A PTFE-lined butterfly valve is an excellent and often more cost-effective choice than valves made from exotic alloys.

- If your primary focus is preventing leakage in a high-purity or sanitary process: The non-stick, inert surface of PTFE is ideal for industries like pharmaceuticals or semiconductor manufacturing.

- If your primary focus is managing high-temperature services or abrasive media: You should evaluate other valve designs, such as metal-seated valves, which are better suited for those challenging conditions.

By intelligently combining materials, the PTFE-lined butterfly valve delivers specialized performance where it matters most.

Summary Table:

| Component | Primary Material | Key Function |

|---|---|---|

| Liner | PTFE (Teflon™) | Provides a chemically inert barrier against corrosion |

| Seat | Rubber (e.g., EPDM, FKM) | Supplies flexibility for a bubble-tight, compressive seal |

| Body | Metal (e.g., Carbon Steel, Ductile Iron) | Offers structural strength and pressure containment |

Need a reliable, corrosion-resistant valve for your critical process?

KINTEK specializes in manufacturing high-performance PTFE components, including custom-fabricated liners and seals for valves and other critical equipment. Our precision production ensures a perfect fit and long-lasting performance for the semiconductor, medical, laboratory, and industrial sectors.

Let us help you solve your toughest chemical handling challenges—from prototype to high-volume production.

Contact KINTEK today for a custom solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability