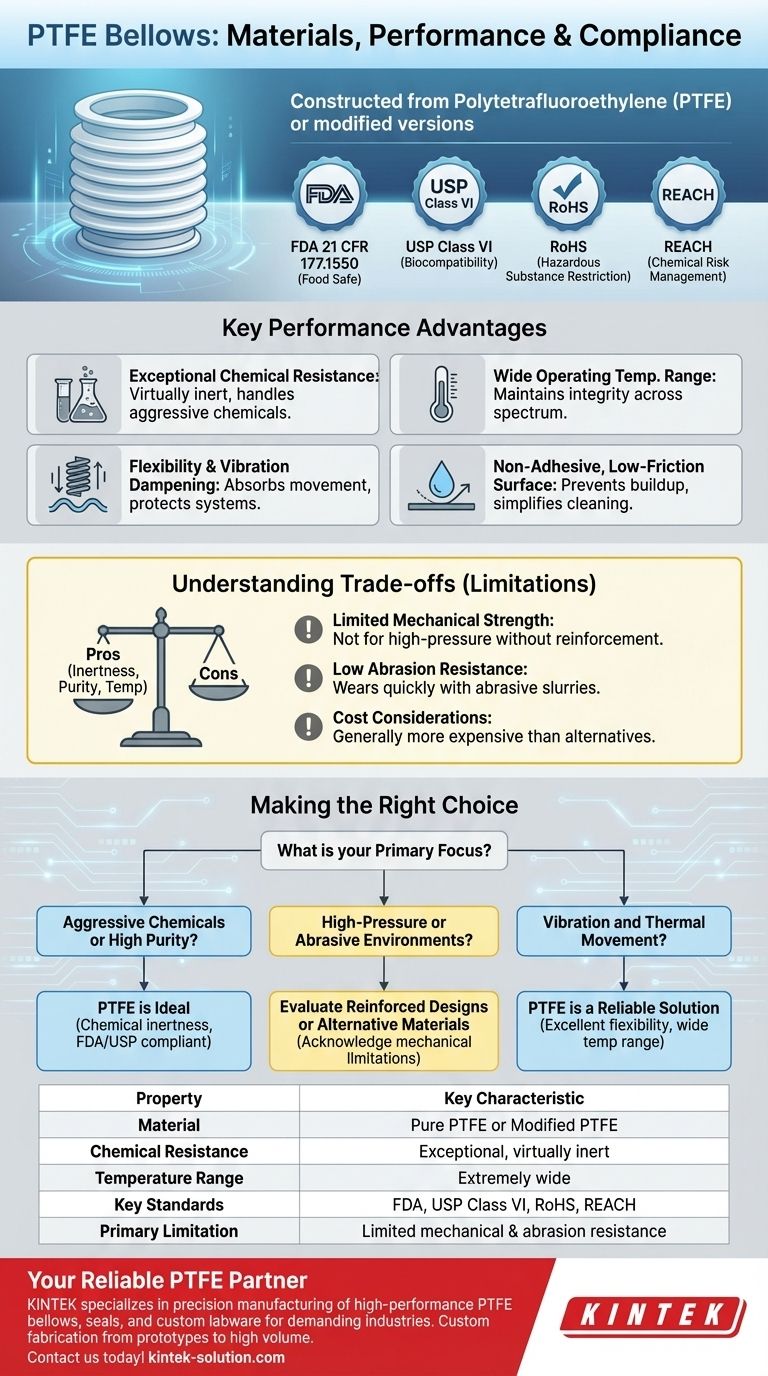

Fundamentally, PTFE bellows are constructed from Polytetrafluoroethylene (PTFE) or its modified versions. These materials are chosen for their unique properties and must comply with critical industry standards, including FDA 21 CFR 177.1550, USP Class VI, RoHS, and REACH, ensuring their safety and suitability for demanding applications.

While PTFE bellows offer unparalleled resistance to chemicals and extreme temperatures, they are not a universal solution. The key to their proper application lies in understanding the trade-off between their exceptional chemical inertness and their inherent mechanical limitations.

The Core Properties of PTFE Bellows

Choosing a PTFE bellow is a decision driven by its distinct performance advantages in specific environments. These properties solve critical engineering challenges related to system integrity and longevity.

Exceptional Chemical Resistance

PTFE is virtually inert. This allows it to handle a vast range of aggressive chemicals, solvents, and corrosive media without degrading or contaminating the process fluid.

This makes it an essential material in the chemical processing, pharmaceutical, and semiconductor industries.

Wide Operating Temperature Range

PTFE bellows maintain their integrity and flexibility across an extremely broad temperature spectrum.

They effectively compensate for thermal expansion and contraction in piping systems, preventing stress and potential failure.

Inherent Flexibility and Vibration Dampening

These components are designed to absorb movement and vibration between system parts.

By acting as a flexible connector, a PTFE bellow protects sensitive equipment from mechanical stress, misalignment, and harmonic vibrations, extending the operational life of the entire system.

Non-Adhesive, Low-Friction Surface

PTFE is designed to repel other materials, resulting in a non-stick surface.

This characteristic is critical for hygiene, as it prevents media from building up within the convolutions of the bellow. It also ensures smooth flow and simplifies cleaning processes, a key requirement in food, beverage, and biotech applications.

Understanding the Trade-offs

No material is perfect for every scenario. Acknowledging the limitations of PTFE is crucial for avoiding misapplication and ensuring system reliability.

Limited Mechanical Strength

The primary limitation of standard PTFE is its relatively low tensile strength. This makes unreinforced bellows unsuitable for high-pressure systems.

For such applications, alternative materials or specially reinforced PTFE designs must be considered.

Low Abrasion Resistance

PTFE is a soft material and can wear quickly when exposed to abrasive slurries or high-velocity particulate matter.

In environments with significant abrasion, PTFE may not be the most durable or cost-effective choice compared to harder materials like rubber or certain composites.

Cost Considerations

PTFE is often more expensive than common alternatives like rubber or standard elastomers.

The decision to use PTFE must be justified by the application's need for its unique chemical, thermal, or purity benefits, which often outweigh the initial material cost.

Key Compliance and Safety Standards

The standards that PTFE bellows meet are not just certifications; they are guarantees of safety and performance for specific industries.

FDA 21 CFR 177.1550

This U.S. Food and Drug Administration regulation confirms that the material is safe for direct contact with food, beverages, and pharmaceuticals. It ensures no harmful substances will leach into the product.

USP Class VI

The United States Pharmacopeia (USP) Class VI standard is a rigorous biocompatibility test for plastics used in medical devices and pharmaceutical manufacturing. Compliance signals the material is non-toxic and suitable for high-purity applications.

RoHS & REACH

These European Union regulations restrict the use of specific hazardous materials (RoHS) and manage the risks posed by chemicals (REACH). Compliance demonstrates environmental responsibility and is often a requirement for products sold in the EU.

Making the Right Choice for Your Application

Selecting the correct bellow requires balancing your primary engineering goal against the material's performance profile.

- If your primary focus is handling aggressive chemicals or high-purity media: PTFE is the ideal choice due to its chemical inertness and compliance with FDA and USP standards.

- If your primary focus is operating in high-pressure or abrasive environments: You must acknowledge PTFE's mechanical limitations and evaluate reinforced designs or alternative materials.

- If your primary focus is compensating for vibration and thermal movement: PTFE offers excellent flexibility and a wide temperature range, making it a reliable solution for protecting mechanical systems.

By weighing these factors, you can confidently determine if a PTFE bellow is the optimal solution for your specific challenge.

Summary Table:

| Property | Key Characteristic |

|---|---|

| Material | Pure PTFE or Modified PTFE |

| Chemical Resistance | Exceptional, virtually inert |

| Temperature Range | Extremely wide |

| Key Standards | FDA 21 CFR 177.1550, USP Class VI, RoHS, REACH |

| Primary Limitation | Limited mechanical strength and abrasion resistance |

Need a reliable PTFE component solution for your demanding application?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including bellows, seals, liners, and custom labware. We understand the critical balance between chemical inertness, purity compliance, and mechanical requirements in industries like semiconductor, medical, and pharmaceutical manufacturing.

We offer custom fabrication from prototypes to high-volume orders, ensuring your components meet the exact specifications and standards your application demands.

Contact KINTEK today to discuss your project and leverage our expertise in PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What should be placed between a shirt and a heat press? Protect Your Gear with the Right Barrier

- What materials are used for jacket profiles and springs in PTFE seals? A Guide to Material Selection

- Why is Teflon suitable for bridge bearing pads? Unlock Smooth, Durable Movement for Your Structure

- What are some examples of chemicals with Excellent (A) resistance for all filler types in Filled PTFE? | Key Compatible Chemicals

- Why are PTFE O-rings suitable for food production machinery? Ensuring Purity and Performance

- What are the key properties of PTFE that make it suitable for machining? Leverage Its Unique Qualities for Precision Components

- Why is PTFE sometimes etched and how is this process performed? Unlock Strong Bonding for Your PTFE Components

- What are the limitations of PTFE in terms of fabrication? Navigating Manufacturing Challenges