At its core, the manufacturing of Polytetrafluoroethylene (PTFE) seals is a multi-stage process that transforms raw resin into a high-performance component. The primary methods involve shaping the material through compression molding or extrusion, followed by a critical heat treatment phase and precision finishing via CNC machining to achieve exact dimensions.

The journey from raw PTFE powder to a finished seal is not a single action but a carefully controlled sequence. Each step—from initial forming to final machining—is essential for creating a seal with the desired chemical resistance, temperature tolerance, and mechanical strength.

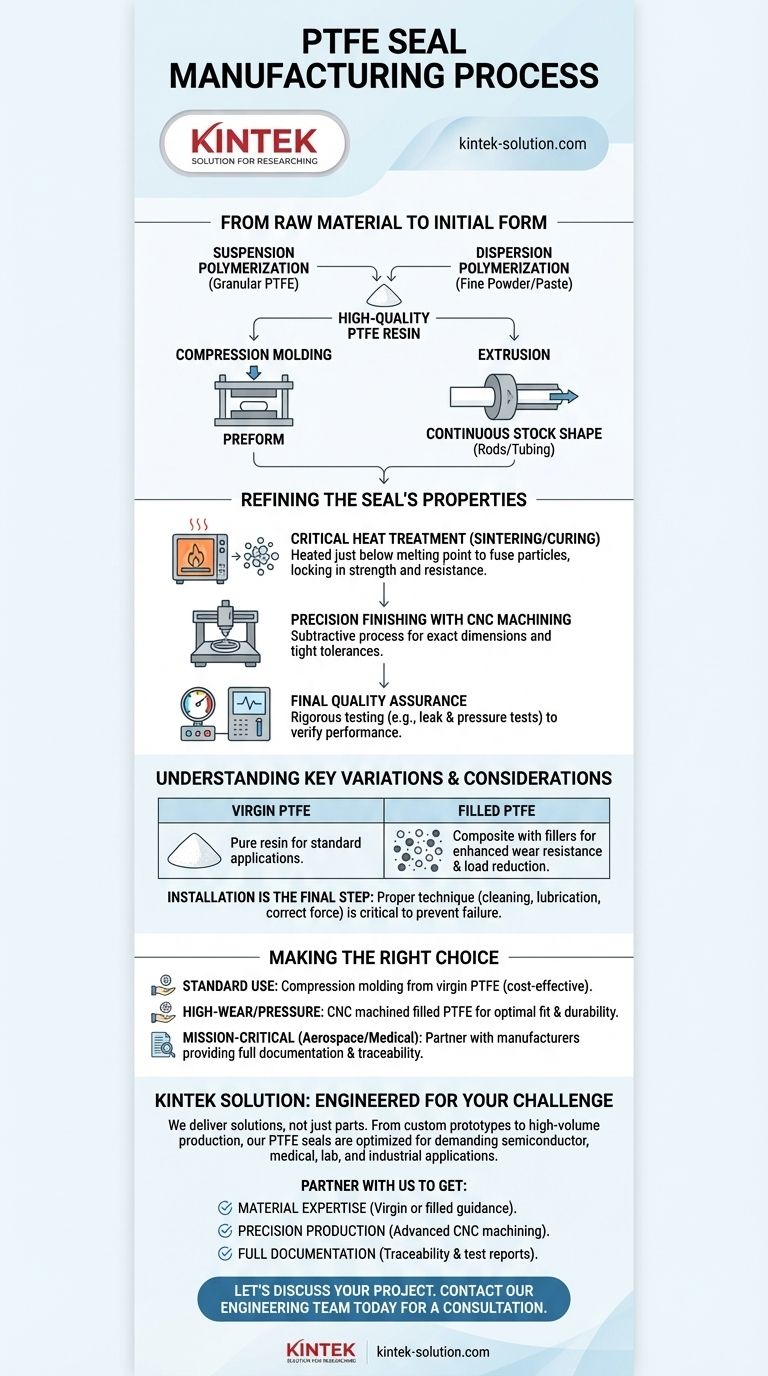

From Raw Material to Initial Form

The quality of the final seal begins with the base polymer. The properties of the seal are locked in during these foundational shaping and forming stages.

Starting with the Right Resin

The process starts with high-quality PTFE resins. These are created through either suspension polymerization, which produces granular PTFE, or dispersion polymerization, which yields a fine powder or paste. The choice of raw material form depends on the subsequent manufacturing method.

Compression Molding

For many seal shapes and sizes, compression molding is the standard. In this method, a pre-measured amount of PTFE powder or granules is placed into a mold cavity. The application of immense pressure and heat causes the material to conform to the shape of the mold, creating a "preform" of the seal.

Extrusion for Continuous Shapes

When creating stock shapes like rods or tubing that will later be machined, extrusion is used. The PTFE material is forced through a die to create a long, continuous profile. This is an efficient way to produce the raw stock for high-volume seal production.

Refining the Seal's Properties

An unrefined PTFE preform lacks the durability required for demanding applications. The next steps in the process are designed to enhance its mechanical properties and ensure it meets precise specifications.

The Critical Heat Treatment Stage

After initial shaping, the seal undergoes a heat treatment process, often called curing or sintering (frittage). The part is heated to a high temperature, just below its melting point, which causes the PTFE particles to fuse together. This step is crucial for locking in the seal's mechanical strength and resistance characteristics.

Precision Finishing with CNC Machining

The sintered part is a semi-finished product. To achieve the final, precise dimensions required for a reliable seal, it is finished using Computer Numerical Control (CNC) machining. This subtractive process removes excess material to meet tight tolerances for diameter, thickness, and any sealing features.

Final Quality Assurance

The last step of manufacturing is rigorous testing. Finished seals undergo checks, including leak and pressure tests, to verify they meet performance standards and will function reliably in their intended application.

Understanding Key Variations and Considerations

Not all PTFE seals are created equal. The manufacturing process can be adjusted to produce seals with vastly different performance characteristics.

Virgin PTFE vs. Filled PTFE

While many seals are made from pure, or "virgin," PTFE, others are made from "filled" grades. Filled PTFE is a composite material where fillers like carbon, glass fiber, or graphite are blended with the PTFE resin before molding. This is done to enhance specific properties, such as improving wear resistance or reducing deformation under load.

Installation is the Final Manufacturing Step

A perfectly manufactured seal can fail if installed incorrectly. Proper installation—including cleaning mating surfaces, using appropriate lubrication, and applying correct, even force—is the final and critical step in ensuring the seal performs as designed. Over-tightening can easily deform the soft PTFE material and compromise its integrity.

Making the Right Choice for Your Application

Selecting the right seal requires understanding how its manufacturing process aligns with your performance needs.

- If your primary focus is standard industrial use: Seals produced via compression molding from virgin PTFE and finished to standard tolerances are often sufficient and cost-effective.

- If your primary focus is high-wear or high-pressure environments: Specify a seal made from a filled PTFE compound that is precision CNC machined for optimal fit and durability.

- If your primary focus is mission-critical reliability (aerospace, medical): Partner with a manufacturer that provides documentation of their end-to-end process, including material traceability and post-production pressure testing.

Understanding how a PTFE seal is made empowers you to select a component that is not just compatible, but truly optimized for your specific engineering challenge.

Summary Table:

| Process Step | Key Function | Outcome |

|---|---|---|

| Compression Molding / Extrusion | Initial shaping of PTFE resin | Creates a preform or stock shape |

| Sintering (Heat Treatment) | Fuses PTFE particles | Locks in mechanical strength & chemical resistance |

| CNC Machining | Precision finishing | Achieves exact dimensions and tight tolerances |

| Quality Assurance | Validates performance | Ensures reliability via pressure and leak tests |

Need a PTFE seal engineered for your specific challenge?

At KINTEK, we don't just supply parts—we deliver solutions. Our expertise in precision manufacturing, from custom prototypes to high-volume production, ensures your PTFE seals (and other critical components like liners and labware) are optimized for performance in the most demanding semiconductor, medical, laboratory, and industrial applications.

Partner with us to get:

- Material Expertise: Guidance on virgin or filled PTFE compounds for your exact needs.

- Precision Production: Advanced CNC machining for seals that fit perfectly, every time.

- Full Documentation: Complete traceability and test reports for mission-critical reliability.

Let's discuss your project. Contact our engineering team today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining