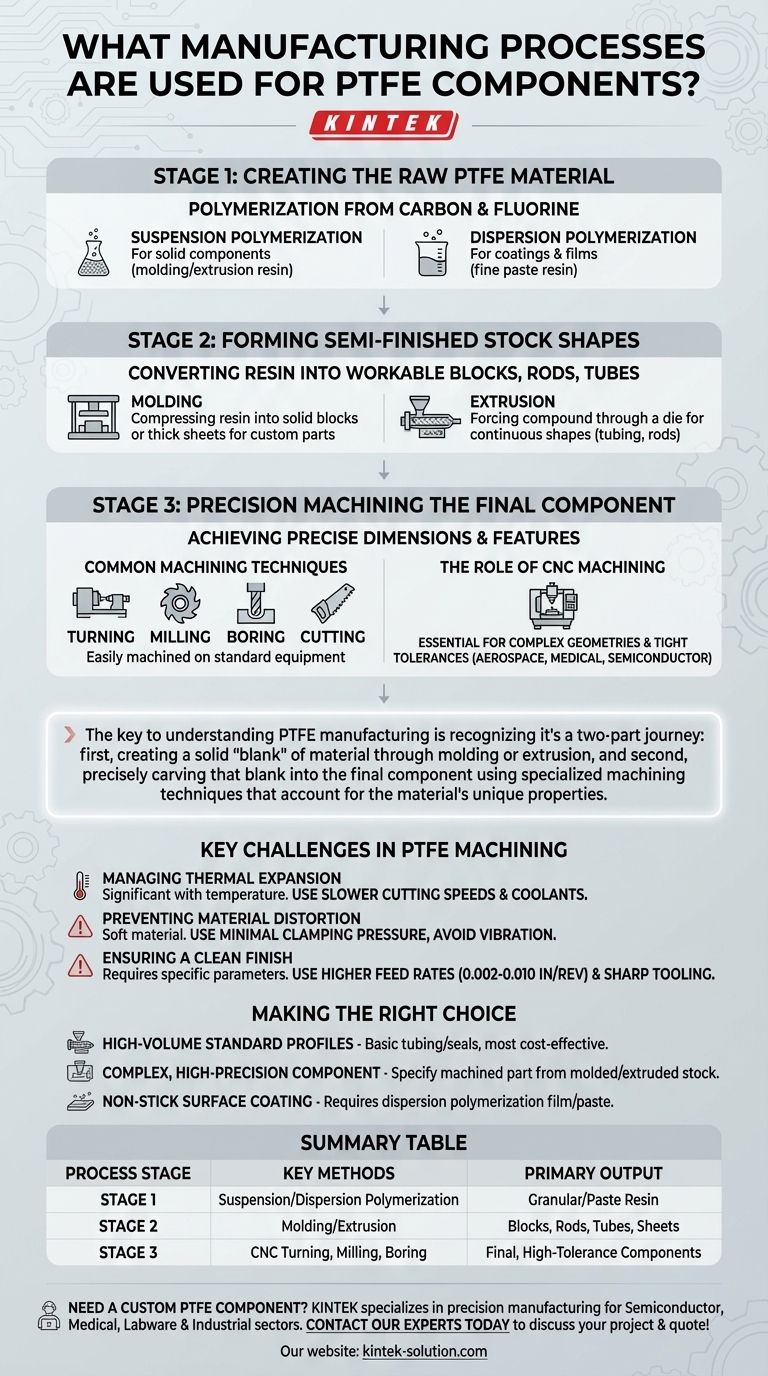

To manufacture PTFE components, a multi-stage process is typically used, beginning with creating the raw material, forming it into a semi-finished stock shape, and then machining it to final specifications. The primary methods for forming stock are molding and extrusion, while the final, precise shape is achieved through CNC machining techniques like turning, milling, and boring.

The key to understanding PTFE manufacturing is recognizing it's a two-part journey: first, creating a solid "blank" of material through molding or extrusion, and second, precisely carving that blank into the final component using specialized machining techniques that account for the material's unique properties.

Stage 1: Creating the Raw PTFE Material

Before any shaping can occur, the Polytetrafluoroethylene polymer must be created from its core chemical components, carbon and fluorine. This is done through polymerization.

Suspension Polymerization for Solids

This is the most common method for creating the granular or pelletized PTFE resin used in manufacturing solid components. The resulting material is ideal for molding and extrusion processes.

Dispersion Polymerization for Coatings

This method produces a finer, paste-like PTFE. This form is not used for solid components but is essential for creating non-stick coatings and films applied to other materials.

Stage 2: Forming Semi-Finished Stock Shapes

Once the raw PTFE resin is created, it is converted into a solid, workable form known as a "stock shape." This provides the raw material for the final machining stage.

Molding

In this process, PTFE resin is compressed into a mold to create solid blocks, rods, or thick sheets. This is the foundational step for producing larger, custom-machined parts.

Extrusion

For continuous shapes like tubing, thin rods, or specific profiles, extrusion is used. The PTFE compound is forced through a die to create a long, uniform shape, which can then be cut to length.

Stage 3: Precision Machining the Final Component

Machining is the critical final step where the semi-finished stock shape is transformed into a finished component with precise dimensions and features.

Common Machining Techniques

PTFE is easily machined on standard equipment. Common processes include turning on a lathe, milling to create complex surfaces, boring to create accurate holes, and cutting to size.

The Role of CNC Machining

For parts with complex geometries or that require tight tolerances, Computer Numerical Control (CNC) equipment is essential. Multi-axis CNC machines and advanced programming allow for the high precision demanded by industries like aerospace, medical, and semiconductor manufacturing.

Why Machining is So Common

Unlike many plastics that can be injection molded directly into a final shape, PTFE's high melt viscosity makes this impractical. Its natural resilience also means that machining is a reliable way to achieve final dimensions, as the material can conform slightly to its working environment.

Key Challenges in PTFE Machining

Successfully machining PTFE requires a deep understanding of its unique properties. Ignoring these can lead to poor quality, scrapped parts, and production delays.

Managing Thermal Expansion

PTFE expands and contracts significantly with temperature changes. Heat generated during machining can ruin dimensional accuracy. Slower cutting speeds and the use of coolant systems are critical to manage this.

Preventing Material Distortion

PTFE is a soft material. Excessive clamping pressure in a CNC machine will deform the part, leading to inaccurate cuts. Machinists must use minimal clamping pressure and avoid excessive vibration.

Ensuring a Clean Finish

Achieving a smooth surface without burrs requires specific parameters. This is often accomplished with higher feed rates (the speed at which the tool moves across the material) and extremely sharp tooling. Recommended feed rates are typically between 0.002 to 0.010 inches per revolution.

Making the Right Choice for Your Application

Understanding this manufacturing flow is essential for sourcing or designing PTFE components that meet your exact needs.

- If your primary focus is high-volume standard profiles: Parts created directly from extrusion, such as basic tubing or seals, are the most cost-effective solution.

- If your primary focus is a complex, high-precision component: You must specify a machined part created from a molded or extruded stock shape.

- If your primary focus is a non-stick surface coating: Your application requires PTFE material created through dispersion polymerization, which is then applied as a film or paste.

Ultimately, controlling the entire process—from raw polymer to the final machined part—is the only way to guarantee a component that performs reliably in its critical application.

Summary Table:

| Process Stage | Key Methods | Primary Output |

|---|---|---|

| Stage 1: Material Creation | Suspension Polymerization, Dispersion Polymerization | Granular/Paste PTFE Resin |

| Stage 2: Forming Stock Shapes | Molding, Extrusion | Blocks, Rods, Tubes, Sheets |

| Stage 3: Precision Machining | CNC Turning, Milling, Boring | Final, High-Tolerance Components |

Need a custom PTFE component that meets your exact specifications? KINTEK specializes in the precise manufacturing of PTFE seals, liners, labware, and more for the semiconductor, medical, laboratory, and industrial sectors. From prototype to high-volume production, we ensure superior performance by mastering every stage of the PTFE manufacturing process.

Contact our experts today to discuss your project and receive a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials