Teflon's remarkable versatility is not due to a single trait, but a unique combination of three core properties. Its extreme chemical inertness, broad thermal stability, and an exceptionally low coefficient of friction allow it to solve problems in environments where most other materials would degrade or fail.

The true value of Teflon (PTFE) lies in its passive, non-reactive nature. It excels in applications where it must resist extreme chemical, thermal, or mechanical stress without degrading, contaminating its environment, or interfering with a system's operation.

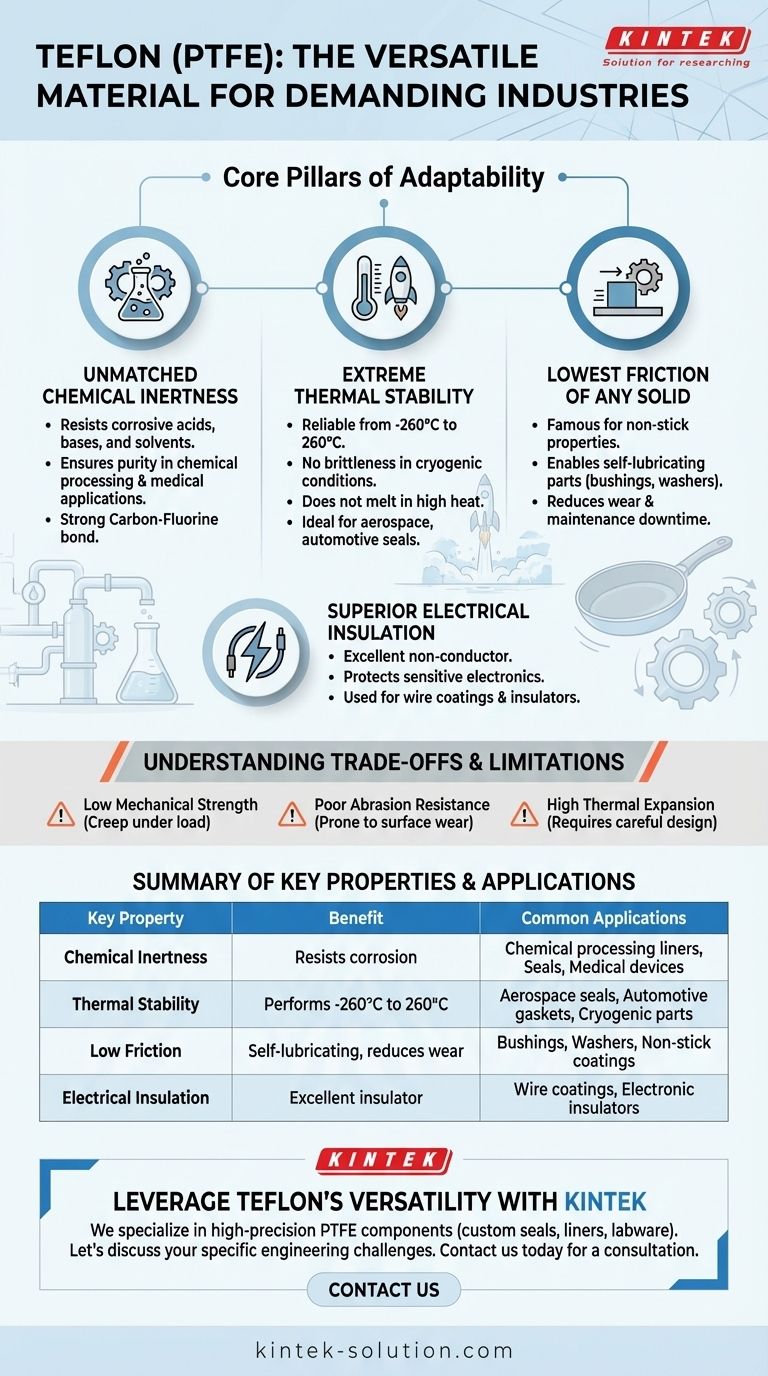

The Core Pillars of Teflon's Adaptability

Teflon's wide-ranging use is a direct result of a few powerful molecular characteristics. Understanding these foundational properties explains its presence in everything from aerospace to medical devices.

Unmatched Chemical Inertness

The carbon-fluorine bond in Polytetrafluoroethylene (PTFE) is one of the strongest in organic chemistry. This makes the material almost completely inert.

This inertness means Teflon can be used to handle highly corrosive acids, bases, and solvents without degrading, making it essential for gaskets, valve seats, and liners in chemical processing. This property also ensures biocompatibility for medical applications.

Extreme Thermal Stability

Teflon performs reliably across an exceptionally wide temperature range, typically from -260°C to 260°C (-436°F to 500°F).

It does not become brittle in cryogenic conditions nor does it melt or lose integrity in high-heat industrial processes. This makes it a go-to material for seals and components in automotive, aerospace, and heavy machinery.

The Lowest Friction of Any Solid

Teflon has an extremely low coefficient of friction, famously demonstrated by its use in non-stick cookware. This "slipperiness" is incredibly valuable in mechanical systems.

This property allows it to be used for self-lubricating parts like bushings and washers, reducing wear between moving components and often eliminating the need for oil-based lubricants. This enhances equipment reliability and reduces maintenance downtime.

Superior Electrical Insulation

In addition to its other properties, Teflon is an excellent electrical insulator. It does not conduct electricity, which is critical for protecting sensitive electronic components.

This makes it an ideal material for coating wires and manufacturing insulators used in electronics and telecommunications, where signal integrity is paramount.

Understanding the Trade-offs and Limitations

No material is perfect, and its versatility does not make it the universal solution. Being objective about Teflon's limitations is key to using it effectively.

Low Mechanical Strength

Teflon is a relatively soft material. It can be prone to "creep," meaning it can slowly deform under a constant load, which makes it unsuitable for high-load structural applications.

Poor Abrasion Resistance

While it has low friction, Teflon is not highly resistant to abrasion. Abrasive materials can scratch and wear away its surface, which is a key consideration in high-wear mechanical systems.

High Thermal Expansion

Teflon expands and contracts with temperature changes more than metals do. Engineers must account for this in designs requiring tight tolerances to prevent parts from failing under thermal cycling.

Making the Right Choice for Your Application

To leverage Teflon's strengths, you must align its properties with your primary engineering goal.

- If your primary focus is purity or corrosion resistance: Its chemical inertness makes it the definitive choice for lining pipes, creating seals, and handling fluids in the chemical, food processing, and semiconductor industries.

- If your primary focus is reducing friction and wear: Its low-friction surface is ideal for creating self-lubricating bushings, washers, and non-stick coatings where smooth, efficient movement is critical.

- If your primary focus is performance in extreme temperatures: Its thermal stability ensures reliability for gaskets, seals, and insulation in demanding aerospace, automotive, and industrial environments.

Ultimately, Teflon's value lies in its unique ability to perform reliably where other materials simply cannot.

Summary Table:

| Key Property | Benefit | Common Applications |

|---|---|---|

| Chemical Inertness | Resists corrosion from acids, bases, and solvents | Chemical processing liners, seals, medical devices |

| Thermal Stability | Performs from -260°C to 260°C | Aerospace seals, automotive gaskets, cryogenic parts |

| Low Friction | Self-lubricating, reduces wear | Bushings, washers, non-stick coatings |

| Electrical Insulation | Excellent insulator, protects components | Wire coatings, electronic insulators |

Leverage Teflon's Versatility for Your Most Demanding Applications

At KINTEK, we specialize in manufacturing high-precision PTFE components that harness these unique properties. Whether you need custom seals, liners, labware, or complex fabricated parts for the semiconductor, medical, laboratory, or industrial sectors, we deliver solutions that ensure reliability, purity, and performance.

Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your components meet exact specifications. Let's discuss how our PTFE solutions can solve your specific engineering challenges.

Contact us today for a consultation

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- How is PTFE utilized in the medical and pharmaceutical industries? Ensure Purity and Biocompatibility

- What is PTFE material and what are its key properties? A Guide to the Ultimate High-Performance Polymer

- What is Teflon/PTFE material and what are its key properties? Unlock Its High-Performance Capabilities

- How does PTFE's low friction property benefit mechanical engineering applications? Achieve Efficiency and Reliability

- What gives PTFE its UV resistance? The Science of Inherent Molecular Stability

- How can waste from PTFE manufacturing be reused? Transform Scrap into High-Performance Micropowder

- How does Teflon contribute to the effectiveness of sunscreens? Enhancing Durability and Water Resistance

- How chemically resistant is PTFE? Discover its near-total inertness to most chemicals