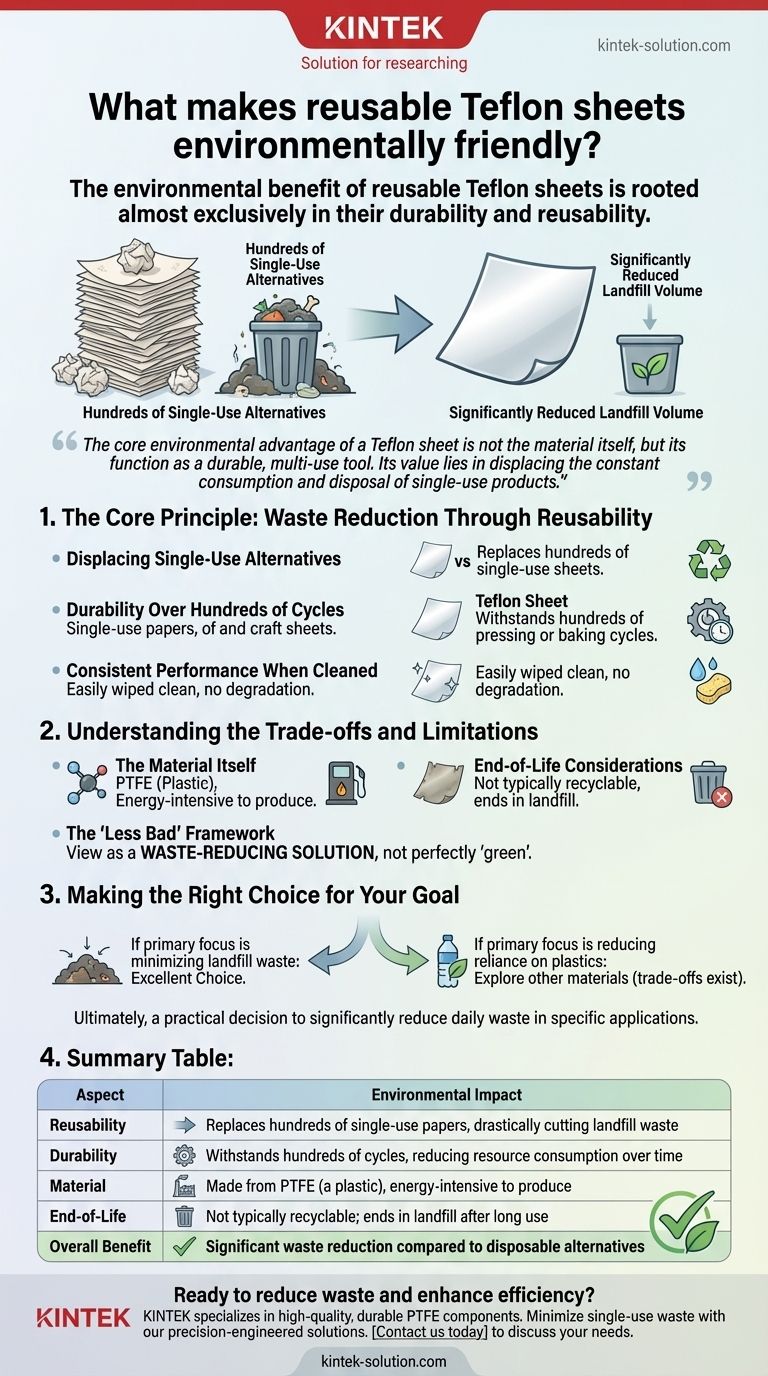

The environmental benefit of reusable Teflon sheets is rooted almost exclusively in their durability and reusability. By replacing hundreds of single-use alternatives like parchment paper, they significantly reduce the volume of waste sent to landfills from applications like heat pressing or baking.

The core environmental advantage of a Teflon sheet is not the material itself, but its function as a durable, multi-use tool. Its value lies in displacing the constant consumption and disposal of single-use products.

The Core Principle: Waste Reduction Through Reusability

The "eco-friendly" label for Teflon sheets is a direct result of their role in waste minimization. They are designed to be used repeatedly, which fundamentally changes their environmental impact compared to disposable options.

Displacing Single-Use Alternatives

The most common comparison is with single-use parchment or craft paper. A single Teflon sheet can perform the same function as hundreds of these disposable sheets over its lifespan.

This direct replacement drastically cuts down on the constant cycle of using and discarding paper products, which consumes resources in manufacturing and contributes to landfill volume.

Durability Over Hundreds of Cycles

High-quality Teflon sheets are engineered to withstand hundreds of pressing or baking cycles without significant degradation.

This robustness ensures a long service life, making them a cost-effective and resource-conscious choice for anyone who performs these tasks frequently.

Consistent Performance When Cleaned

Unlike disposable papers, Teflon sheets can be easily wiped clean after each use.

Crucially, this cleaning process does not degrade their non-stick performance, allowing them to be reused consistently until they reach the end of their physical lifespan.

Understanding the Trade-offs and Limitations

To make a truly informed decision, it's critical to look beyond the benefit of reusability and understand the full context of the material. A product is rarely, if ever, universally "eco-friendly."

The Material Itself

Teflon is the brand name for Polytetrafluoroethylene (PTFE), a type of plastic. Like other plastics, it is a synthetic polymer derived from non-renewable resources, and its manufacturing process is energy-intensive.

End-of-Life Considerations

When a Teflon sheet becomes worn, discolored, or warped, it must be replaced. PTFE is not typically recyclable through standard municipal programs.

This means that at the end of its long life, the sheet itself will likely end up in a landfill. The environmental win is in reducing the total volume of waste, not in eliminating it entirely.

The "Less Bad" Framework

It is most accurate to view reusable Teflon sheets not as a perfectly "green" product, but as a waste-reducing solution.

They represent a significant improvement over a highly wasteful alternative (single-use paper) but still carry the environmental baggage of a plastic product, particularly concerning its production and eventual disposal.

Making the Right Choice for Your Goal

Your decision should be based on a clear understanding of what environmental goal you are prioritizing.

- If your primary focus is minimizing landfill waste: A reusable Teflon sheet is an excellent choice, as it directly replaces a significant volume of single-use paper.

- If your primary focus is reducing reliance on plastics: You may want to explore other materials, but be aware of the potential trade-offs in durability, performance, and reusability.

Ultimately, choosing a reusable Teflon sheet is a practical decision to significantly reduce daily waste in specific applications.

Summary Table:

| Aspect | Environmental Impact |

|---|---|

| Reusability | Replaces hundreds of single-use papers, drastically cutting landfill waste |

| Durability | Withstands hundreds of cycles, reducing resource consumption over time |

| Material | Made from PTFE (a plastic), energy-intensive to produce |

| End-of-Life | Not typically recyclable; ends in landfill after long use |

| Overall Benefit | Significant waste reduction compared to disposable alternatives |

Ready to reduce waste and enhance efficiency in your operations? At KINTEK, we specialize in manufacturing high-quality, durable PTFE components—including custom reusable sheets, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision-engineered solutions are built to last, helping you minimize single-use waste while maintaining top performance. Whether you need prototypes or high-volume orders, we deliver reliability and sustainability. Contact us today to discuss your specific needs and discover how KINTEK can support your environmental and operational goals!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What visual feature does the PTFE Lined Spacer have? A Guide to Its High-Performance Design

- Why are PTFE balls particularly suitable for high-performance applications? Key Properties & Selection Guide

- How does a PTFE lined ball valve work? A Guide to Corrosion-Free Flow Control

- What is the biggest advantage of Teflon washers? Achieve Self-Lubricating, Low-Friction Performance

- In what types of environments are PTFE seat butterfly valves most suitable? Ideal for Corrosive, High-Purity Applications

- What benefits do fillers provide to virgin PTFE bushings? Boost Strength & Wear Resistance

- What maintenance practices are recommended for PTFE gaskets? Ensure Long-Term Reliability and Prevent Leaks

- In which industries are PTFE O-rings used? Essential Seals for Extreme Conditions