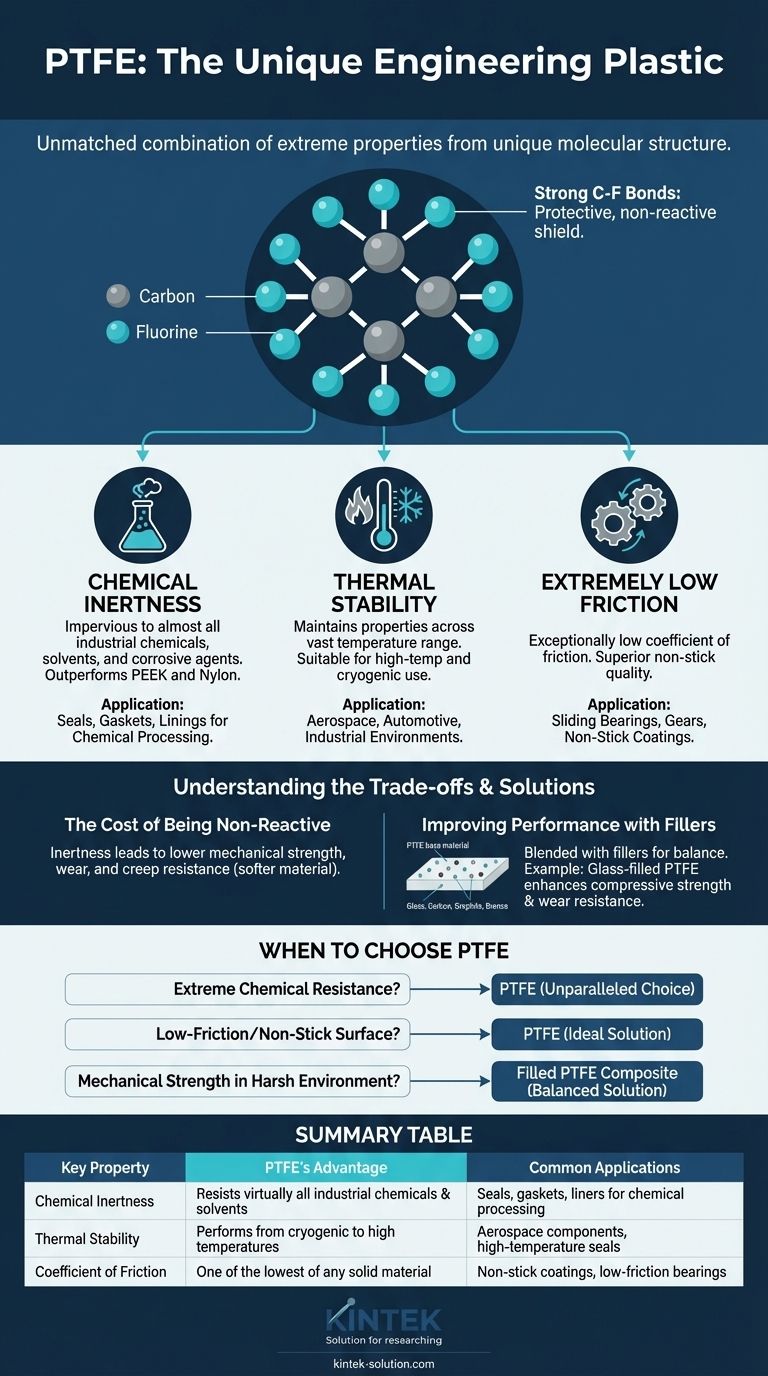

The uniqueness of Polytetrafluoroethylene (PTFE) lies in a rare combination of three extreme properties that other engineering plastics cannot match simultaneously. It offers near-total chemical inertness, exceptional stability across a wide temperature range, and one of the lowest coefficients of friction of any solid material.

At its core, PTFE's exceptional characteristics are not just a list of features but a direct result of its unique molecular structure. The incredibly strong carbon-fluorine bonds create a protective, non-reactive shield that is the source of all its signature properties.

The Foundation of PTFE's Uniqueness: Its Molecular Structure

The Carbon-Fluorine Bond

Unlike most plastics, which are built on a carbon-hydrogen backbone, PTFE's structure consists of a carbon chain surrounded by fluorine atoms.

The bond between carbon and fluorine is exceptionally strong and stable. This creates a dense, non-polar "sheath" of fluorine atoms that protects the vulnerable carbon backbone.

This molecular arrangement is what makes the material so non-reactive and resistant to external forces and chemicals.

Key Properties Where PTFE Excels

Unmatched Chemical Inertness

PTFE is virtually impervious to almost all industrial chemicals, solvents, and corrosive agents.

Its performance in aggressive chemical environments far exceeds that of other high-performance plastics like PEEK and Nylon. This makes it the default choice for seals, gaskets, and linings in the chemical processing industry.

Exceptional Thermal Stability

The material maintains its properties across a vast temperature range, making it suitable for both high-temperature and cryogenic applications where other plastics would become brittle or melt.

This thermal resilience allows PTFE to function reliably in demanding aerospace, automotive, and industrial environments.

Extremely Low Friction

PTFE has an exceptionally low coefficient of friction, surpassed by very few materials. It is famously known for its non-stick quality.

This property makes it superior to plastics like Acetal or Polycarbonate for applications requiring smooth, low-effort movement, such as in sliding bearings, gears, and non-stick coatings.

Understanding the Trade-offs

The Cost of Being Non-Reactive

While PTFE's inertness is its greatest strength, it also leads to its primary weaknesses: relatively low mechanical strength, wear resistance, and creep resistance compared to other engineering plastics.

Because the molecules are so non-reactive, they don't "grip" each other strongly, resulting in a softer material.

Improving Mechanical Performance with Fillers

To overcome these mechanical limitations, PTFE is often blended with fillers. This is how engineers achieve a precise balance of properties for a specific application.

A common example is glass-filled PTFE, which significantly improves compressive strength and wear resistance. This makes it suitable for structural components and high-load bearings where pure PTFE would fail.

Other fillers like carbon, graphite, or bronze can be used to enhance different properties like conductivity or hardness.

When to Choose PTFE

Deciding on PTFE requires matching its unique profile to your specific engineering challenge.

- If your primary focus is extreme chemical resistance: PTFE is the unparalleled choice, offering reliability where nearly all other materials would degrade.

- If your primary focus is creating a low-friction or non-stick surface: PTFE's uniquely low coefficient of friction makes it the ideal solution for sliding components and coatings.

- If your primary focus is mechanical strength in a harsh environment: A filled PTFE composite offers a balanced solution, combining chemical and thermal resistance with enhanced durability.

Ultimately, selecting PTFE is a strategic decision for applications where its specific, extreme properties are not just beneficial, but absolutely critical for success.

Summary Table:

| Key Property | PTFE's Advantage | Common Applications |

|---|---|---|

| Chemical Inertness | Resists virtually all industrial chemicals & solvents | Seals, gaskets, liners for chemical processing |

| Thermal Stability | Performs from cryogenic to high temperatures | Aerospace components, high-temperature seals |

| Coefficient of Friction | One of the lowest of any solid material | Non-stick coatings, low-friction bearings |

Need a custom PTFE component that leverages these unique properties?

KINTEK specializes in the precision manufacturing of PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a prototype or a high-volume order, our expertise ensures your parts meet the exact demands of your application, combining PTFE's superior chemical and thermal resistance with the mechanical performance you need.

Contact our experts today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- How does the structure of ePTFE contribute to its functionality? Unlock Superior Performance with a Unique Microporous Design

- What is the water absorption rate of PTFE after 24 hours? Unlock Unmatched Material Stability

- What are the advantages of using filled PTFE materials? Enhance Strength, Wear, and Stability

- What is Glass-Filled PTFE and what are its properties? A Guide to Enhanced PTFE Performance

- What makes PTFE suitable for piping and tubing systems? Unlock Superior Chemical Resistance and Durability

- What are the advantages of PTFE in chemical processing applications? Ensure Safety, Purity, and Reliability

- What are the key properties of PTFE as a material? Unlock Extreme Performance in Your Application

- What is virgin (unfilled) grade PTFE used for? Essential Applications for Ultimate Purity