The exceptional resistance of PTFE gaskets to heat and chemicals stems from its unique molecular structure. The root of this resilience lies in the powerful and stable bond between its carbon and fluorine atoms, which is one of the strongest single bonds found in organic chemistry. This bond creates an incredibly non-reactive and thermally stable material.

At its core, PTFE’s legendary performance is not just a material property; it is a direct result of its molecular architecture. The tightly packed fluorine atoms act as an impenetrable shield for the carbon backbone, making the material fundamentally inert to chemical attack and thermal degradation.

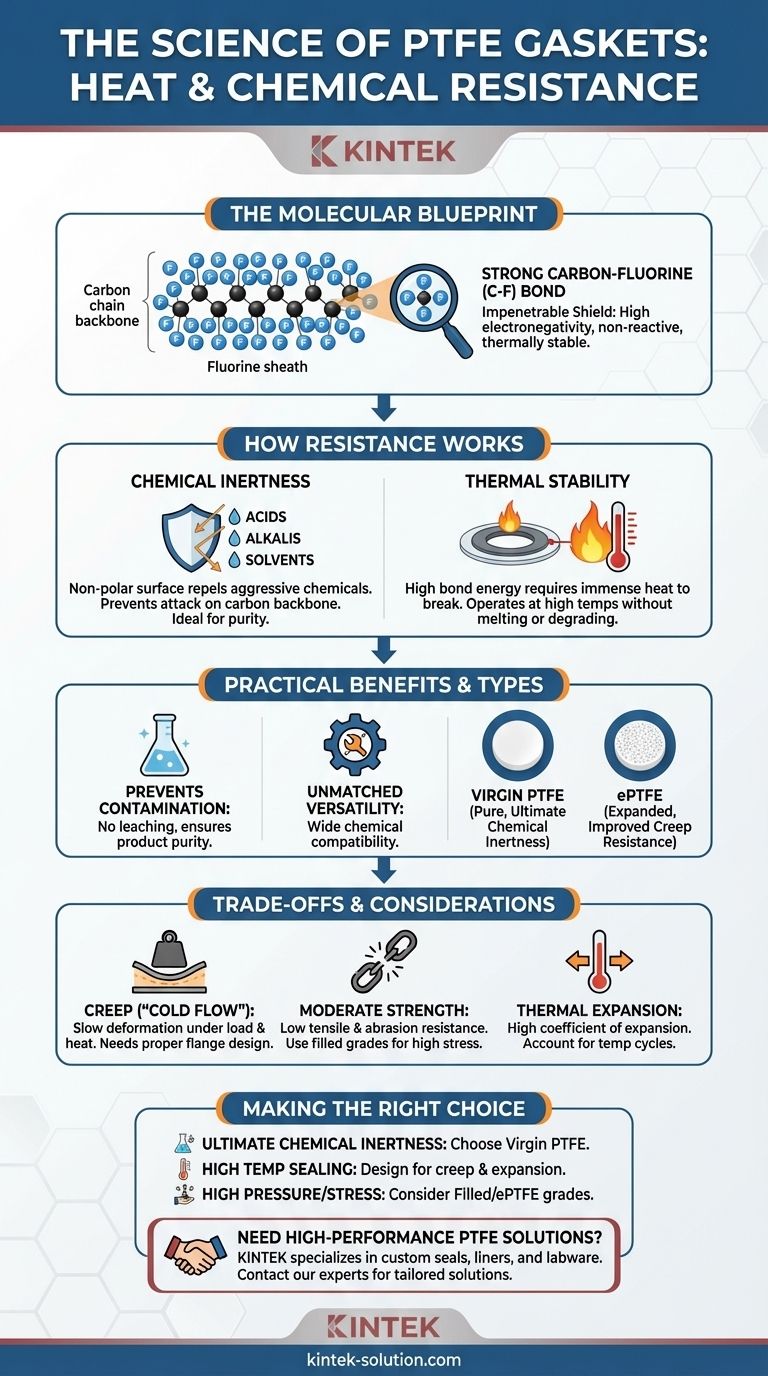

The Molecular Blueprint of PTFE's Resistance

To truly understand why PTFE (Polytetrafluoroethylene) performs so well, we must look at its chemical composition. Its properties are not accidental; they are engineered at the atomic level.

The Carbon-Fluorine Bond: A Chemical Shield

The entire structure of PTFE is based on a chain of carbon atoms, where each carbon is bonded to two fluorine atoms. This Carbon-Fluorine (C-F) bond is extraordinarily strong and short.

Fluorine atoms are highly electronegative and relatively large. They effectively wrap around the carbon chain, creating a dense, uniform "sheath" of fluorine. This protective layer is both physically and electronically stable.

Chemical Inertness Explained

This fluorine sheath is the reason for PTFE's unmatched chemical resistance. It presents a non-polar, low-energy surface to the outside world.

Aggressive chemicals like concentrated acids, alkalis, and solvents simply cannot penetrate this shield to attack the vulnerable carbon backbone. The material remains stable and does not react, making it ideal for industries handling hazardous or corrosive substances.

Thermal Stability Under Pressure

The same C-F bond strength that provides chemical resistance also dictates its thermal performance. A tremendous amount of thermal energy is required to break these bonds and cause the material to degrade.

This intrinsic stability allows PTFE gaskets to operate effectively at high temperatures where other sealing materials would fail, maintaining their integrity without melting or becoming brittle.

Practical Implications in Demanding Environments

This fundamental chemistry translates directly into reliable performance in real-world industrial applications, where purity, safety, and longevity are critical.

Preventing Process Contamination

Because PTFE is chemically inert, it does not leach chemicals or shed particles into the process media. This makes it a superior choice for applications where product purity is non-negotiable, such as in the food, pharmaceutical, and semiconductor industries.

Unmatched Versatility

PTFE's resistance to nearly all industrial chemicals makes it a highly versatile sealing solution. It can be used confidently across a vast spectrum of applications without the need for extensive compatibility testing for different media.

Expanded vs. Virgin PTFE

Expanded PTFE (ePTFE) is created by mechanically stretching virgin PTFE, introducing porosity. This process does not involve additives, meaning ePTFE retains the exceptional chemical resistance of the original material while offering improved mechanical properties like better creep resistance.

Understanding the Trade-offs

While its chemical and thermal properties are elite, no material is perfect. Understanding PTFE's limitations is crucial for proper application and joint design.

Creep or "Cold Flow"

PTFE is a relatively soft material that can be susceptible to creep, which is the tendency to slowly deform over time under a constant load. This is especially true at elevated temperatures and must be accounted for in flange design and bolt torque specifications.

Moderate Mechanical Strength

Pure, or "virgin," PTFE has low tensile strength and abrasion resistance compared to harder plastics or metals. For applications involving high pressure, abrasion, or significant mechanical stress, "filled" grades of PTFE (which include materials like glass, carbon, or graphite) are often required to enhance its physical durability.

Thermal Expansion

PTFE has a relatively high coefficient of thermal expansion, meaning it expands and contracts more than metals with temperature changes. This must be considered in applications with wide temperature cycles to ensure a reliable seal is maintained.

Making the Right Choice for Your Application

Selecting the correct gasket material depends entirely on the demands of your specific environment.

- If your primary focus is ultimate chemical inertness: Virgin PTFE is unparalleled for handling aggressive acids, alkalis, and solvents where product purity is paramount.

- If your primary focus is sealing at high temperatures: PTFE provides excellent thermal stability, but you must select a grade and design the joint to mitigate the effects of creep and thermal expansion.

- If your application involves high pressure or mechanical stress: Consider filled or expanded PTFE grades, which are engineered to improve mechanical properties while retaining the core chemical resistance.

Understanding the molecular foundation of PTFE's properties allows you to deploy it with confidence in the most challenging industrial environments.

Summary Table:

| Property | Advantage | Consideration |

|---|---|---|

| Chemical Resistance | Resists nearly all acids, alkalis, and solvents; prevents contamination. | Unmatched inertness; ideal for pure processes. |

| Thermal Stability | Performs reliably at high continuous temperatures. | Account for thermal expansion and potential creep. |

| Mechanical Properties | Soft and conformable for excellent sealing. | Virgin PTFE has low strength; use filled grades for high stress. |

| Material Forms | Virgin PTFE for purity; ePTFE for improved creep resistance. | Select the grade based on specific application demands. |

Need a PTFE gasket that can handle your most aggressive chemicals and highest temperatures?

At KINTEK, we specialize in manufacturing high-performance PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication, from prototypes to high-volume orders, ensures you get a sealing solution engineered for reliability and longevity.

Let's discuss your application requirements. Contact our experts today for a tailored solution that guarantees performance and purity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications