The fundamental reason PTFE compensators are exceptionally suitable for handling aggressive chemicals is their inherent chemical inertness. Polytetrafluoroethylene (PTFE) is a non-reactive polymer that does not degrade, swell, or corrode when exposed to nearly all industrial chemicals, including strong acids, bases, and organic solvents. This ensures the integrity of both the compensator and the media it transports.

At its core, PTFE acts as an impenetrable shield. Its molecular stability prevents it from reacting with corrosive substances, making it a uniquely reliable material for protecting critical systems from chemical attack and ensuring long-term operational safety.

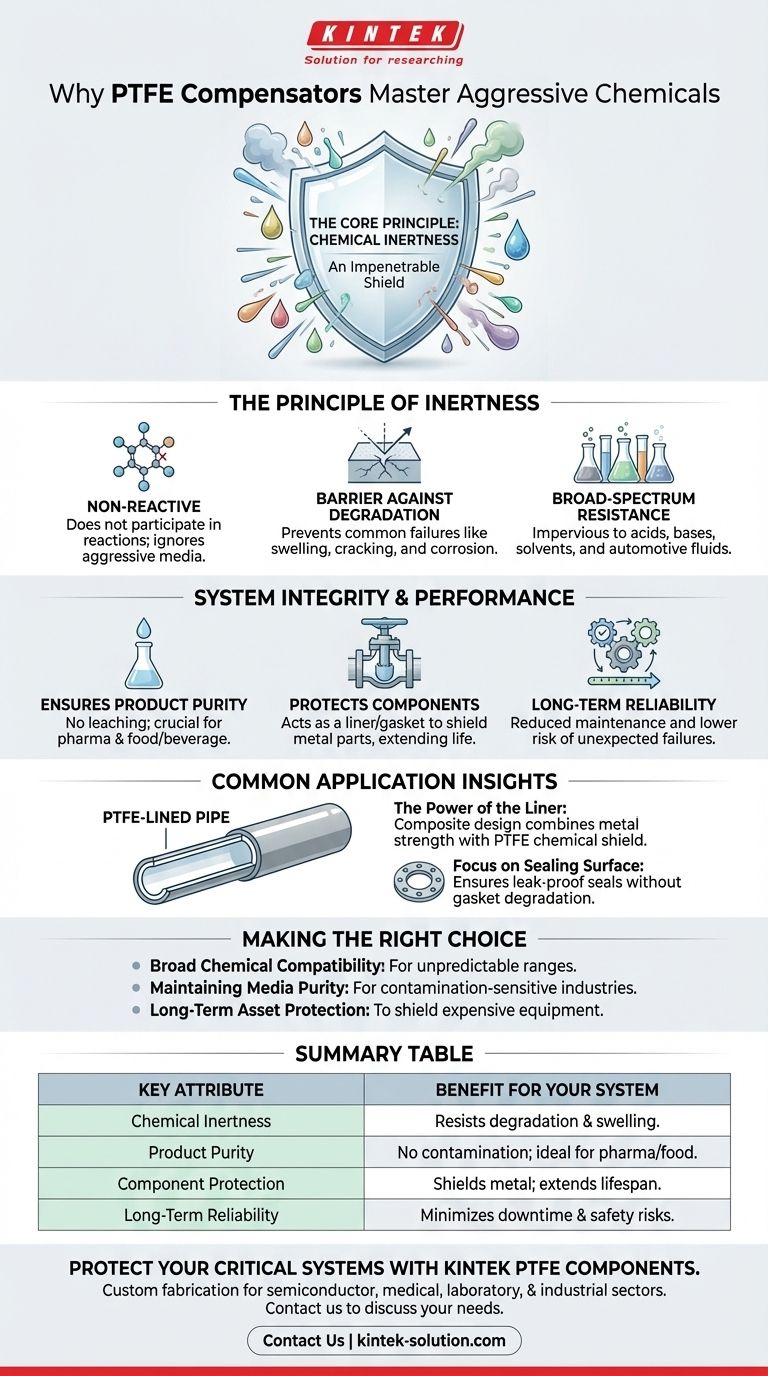

The Principle of Chemical Inertness

The effectiveness of PTFE in harsh environments is not due to a complex mechanism, but a simple and powerful property: it is one of the most non-reactive materials known. This inertness is the foundation of its performance.

What "Inert" Means in Practice

Being chemically inert means that PTFE does not participate in chemical reactions with the substances it contacts. It effectively ignores the presence of aggressive media.

This property prevents common material failures like swelling, cracking, and chemical corrosion that affect other materials over time.

A Barrier Against Degradation

Because PTFE does not degrade, it provides consistent, long-term performance. A compensator made with PTFE maintains its structural and functional properties even after prolonged exposure to harsh chemicals.

This reliability is critical in industrial settings where a component failure can lead to safety hazards and costly downtime.

Broad-Spectrum Chemical Resistance

PTFE's resistance is not limited to a narrow category of chemicals. It is impervious to a vast range of substances, from highly corrosive acids and bases to aggressive solvents and automotive fluids.

This makes it a versatile and dependable choice for chemical processing plants, laboratories, and any piping system where the media is aggressive or variable.

System Integrity and Performance

Beyond simply surviving chemical exposure, PTFE plays a crucial role in maintaining the health and purity of the entire system. It often functions as a protective liner, shielding more vulnerable components.

Ensuring Product Purity

In industries like pharmaceuticals or food and beverage, preventing contamination is paramount. PTFE's non-reactive nature means it will not leach substances into the media being transported.

This guarantees that the purity and integrity of the final product are maintained, a critical requirement for regulatory compliance and quality control.

Protecting Associated Components

PTFE is frequently used as a liner for valves, a core material for gaskets, or an envelope for seals. In these roles, it acts as a barrier, protecting metal components from direct contact with corrosive media.

This design strategy prevents the corrosion of expensive valves and pipes, significantly extending the service life of the entire system.

Long-Term Reliability

The combination of chemical inertness and its protective function results in exceptional long-term reliability. Systems using PTFE compensators benefit from reduced maintenance needs and a lower risk of unexpected failures caused by chemical attack.

Common Application Insights

While PTFE's chemical resistance is nearly absolute, its successful implementation depends on understanding its role within a system. It is most effective when used as the primary chemical barrier.

The Power of the Liner

Many high-performance components are not made of solid PTFE but are PTFE-lined. A metal body provides structural strength, while a PTFE liner provides the chemical shield.

This composite design leverages the best properties of both materials: the mechanical strength of metal and the chemical inertness of PTFE.

Focus on the Sealing Surface

In applications like flange gaskets, the PTFE material ensures that a reliable, leak-proof seal can be maintained without the gasket material itself degrading from chemical exposure.

This is vital for both environmental safety and operational efficiency, preventing leaks of hazardous materials.

Making the Right Choice for Your System

Selecting a PTFE compensator is a strategic decision based on specific operational priorities.

- If your primary focus is broad chemical compatibility: PTFE is an ideal choice for handling a wide or unpredictable range of aggressive chemicals without risk of material failure.

- If your primary focus is maintaining media purity: PTFE's non-reactive properties make it essential for industries like pharmaceuticals or food production where contamination is not an option.

- If your primary focus is long-term asset protection: Using PTFE-lined components is an effective strategy to shield expensive metal piping and equipment from corrosion, maximizing system lifespan.

Ultimately, choosing PTFE is a commitment to operational stability and safety in the most demanding chemical environments.

Summary Table:

| Key Attribute | Benefit for Your System |

|---|---|

| Chemical Inertness | Resists virtually all aggressive chemicals, preventing degradation and swelling. |

| Product Purity | Non-reactive surface ensures no contamination, ideal for pharmaceuticals and food. |

| Component Protection | Shields metal parts from corrosion, extending system lifespan and reducing maintenance. |

| Long-Term Reliability | Maintains performance over time, minimizing downtime and safety risks. |

Protect your critical systems with precision-engineered PTFE components from KINTEK.

Whether you're in the semiconductor, medical, laboratory, or industrial sector, our PTFE compensators, seals, liners, and labware are designed to handle the most aggressive chemicals while ensuring system integrity and product purity. We offer custom fabrication from prototypes to high-volume orders, tailored to your specific needs.

Contact us today to discuss how our PTFE solutions can enhance the safety and reliability of your operations!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications