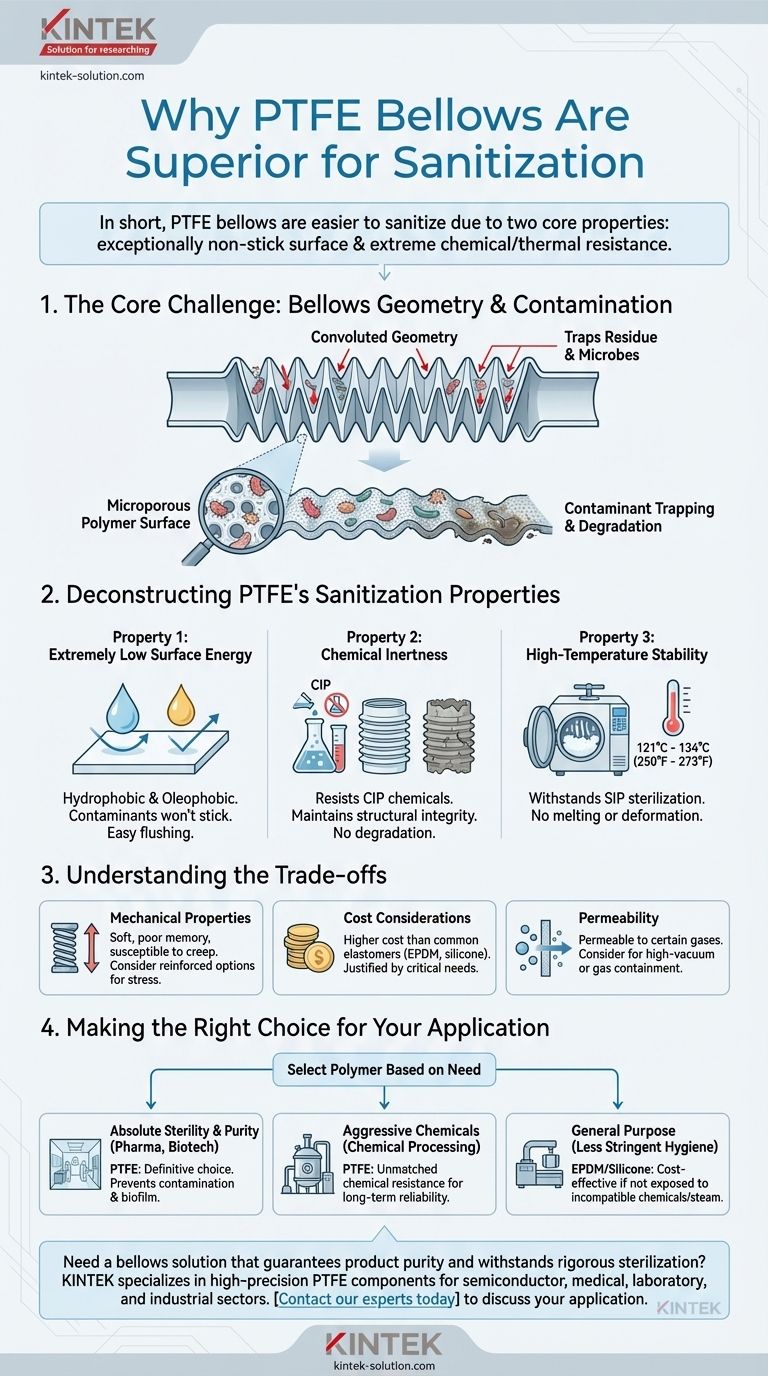

In short, PTFE bellows are easier to sanitize due to two core properties: an exceptionally non-stick surface that prevents contaminants from adhering in the first place, and extreme resistance to the high temperatures and harsh chemicals used in professional sterilization processes. This combination ensures both effective cleaning and material integrity.

The convoluted geometry of bellows creates a high risk for contamination. PTFE's unique combination of non-stick surface properties and chemical/thermal resilience makes it the material of choice for ensuring true sanitary performance where other polymers fail.

The Core Challenge: Why Bellows are a Sanitation Risk

Before analyzing PTFE, it's critical to understand why bellows, regardless of material, present a unique cleaning challenge in hygienic applications.

The Problem of Surface Geometry

The very function of a bellow relies on its folded convolutions. These folds create sharp corners and crevices that are difficult to reach with cleaning fluids.

These areas can easily trap product residue, microorganisms, and cleaning agents, creating a potential breeding ground for biofilm and compromising batch purity.

The Limitation of Standard Polymers

Many common elastomers and plastics can have microporous surfaces that trap contaminants. Over time, repeated exposure to cleaning cycles can also cause these materials to degrade, creating even more surface imperfections for bacteria to colonize.

Deconstructing PTFE's Superior Sanitization Properties

PTFE (Polytetrafluoroethylene) overcomes these challenges due to its fundamental chemical structure. Its performance is not a feature, but an inherent result of its molecular makeup.

Property 1: Extremely Low Surface Energy

PTFE has one of the lowest coefficients of friction of any known solid. Its surface is incredibly hydrophobic (water-repelling) and oleophobic (oil-repelling).

On a molecular level, very little wants to stick to it. This means that residues and microbes have a difficult time gaining an initial foothold on the surface, a critical first step in biofilm formation.

During cleaning, this non-stick property allows contaminants to be flushed away easily and completely, rather than clinging to the material's surface inside the bellow's convolutions.

Property 2: Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, including the aggressive acids, caustics, and solvents used in Clean-in-Place (CIP) systems.

Other polymers might swell, discolor, leach chemicals, or break down when exposed to these cleaners. PTFE maintains its structural integrity, ensuring that the cleaning process itself doesn't damage the component or introduce new contaminants.

Property 3: High-Temperature Stability

Sanitization often relies on high-temperature methods, particularly Steam-in-Place (SIP) processes, which can reach temperatures of 121°C to 134°C (250°F to 273°F).

PTFE is stable at these temperatures and well beyond, showing no degradation, melting, or loss of its beneficial properties. Many other polymers would soften, deform, or fail entirely under these conditions, making true steam sterilization impossible.

Understanding the Trade-offs

While superior for sanitation, PTFE is not the solution for every application. Its unique properties come with specific limitations that must be considered.

Mechanical Properties

PTFE is a relatively soft material with poor memory and a susceptibility to "creep" or cold flow under sustained pressure. In applications with high mechanical stress or abrasion, a different material or a reinforced PTFE might be necessary.

Cost Considerations

High-performance comes at a price. PTFE is significantly more expensive than common elastomers like EPDM or silicone. The cost must be justified by the critical need for purity, chemical resistance, and temperature stability.

Permeability

While its surface is non-porous, PTFE as a material is permeable to certain gases. This is rarely an issue in fluid handling but can be a critical factor in high-vacuum or specific gas-containment applications.

Making the Right Choice for Your Application

Selecting the right polymer requires balancing the need for sanitation with mechanical and budget constraints.

- If your primary focus is absolute sterility and product purity (e.g., pharmaceutical, biotech): PTFE is the definitive choice due to its inertness and superior cleanability, which prevents product contamination and biofilm formation.

- If your primary focus is handling aggressive chemicals (e.g., chemical processing): PTFE's unmatched chemical resistance is the driving factor, making it one of the few viable options for long-term reliability.

- If your primary focus is a general-purpose application with less stringent hygiene needs: A more cost-effective polymer like EPDM or silicone may be perfectly adequate, provided it is not exposed to incompatible chemicals or steam sterilization.

By understanding these fundamental material properties, you can confidently specify a solution that guarantees the required level of sanitation for your critical process.

Summary Table:

| Property | Benefit for Sanitization |

|---|---|

| Low Surface Energy | Prevents contaminants from adhering; allows for easy, complete flushing. |

| Chemical Inertness | Resists degradation from aggressive CIP chemicals, maintaining integrity. |

| High-Temperature Stability | Withstands SIP steam sterilization (up to 134°C / 273°F) without deforming. |

Need a bellow solution that guarantees product purity and withstands rigorous sterilization?

KINTEK specializes in manufacturing high-precision PTFE components, including custom bellows, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a component that delivers unmatched sanitization performance and long-term reliability.

Contact our experts today to discuss your specific application requirements and ensure true sanitary performance in your critical processes.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What is the function of a teflon check valve in control systems? Prevent Backflow in Corrosive & High-Temp Processes

- What are the advantages of PTFE slide bearings over conventional supports? Achieve Frictionless Movement for Durable Structures

- What are the general conclusions about PTFE and PEEK for ball valve seats? PTFE vs. PEEK for Valve Performance

- In which components of a mechanical seal is PTFE commonly used? Solve Sealing Challenges with Chemical Resistance

- What is the recommended method for cleaning Teflon PTFE sheets? A Guide to Preserving Non-Stick Performance

- What other filler materials are used with PTFE besides fiberglass? A Guide to Carbon, Metal & Ceramic Fillers

- What makes ePTFE gaskets effective against gas leakage? The Key to Superior Gas Sealing

- Why is CNC machining suitable for custom Teflon parts? Achieve Precision for Demanding Applications