At its core, Polytetrafluoroethylene (PTFE) is an ideal material for corrosion-resistant applications because it is almost completely chemically inert. Its unique molecular structure, featuring incredibly strong carbon-fluorine bonds, makes it non-reactive to nearly all industrial chemicals, acids, solvents, and caustic agents, ensuring it does not degrade or lose integrity upon exposure.

The true value of PTFE isn't just its chemical resistance, but the fact that this resistance remains stable across an exceptionally wide range of temperatures and physical conditions, making it a uniquely reliable barrier in the most demanding environments.

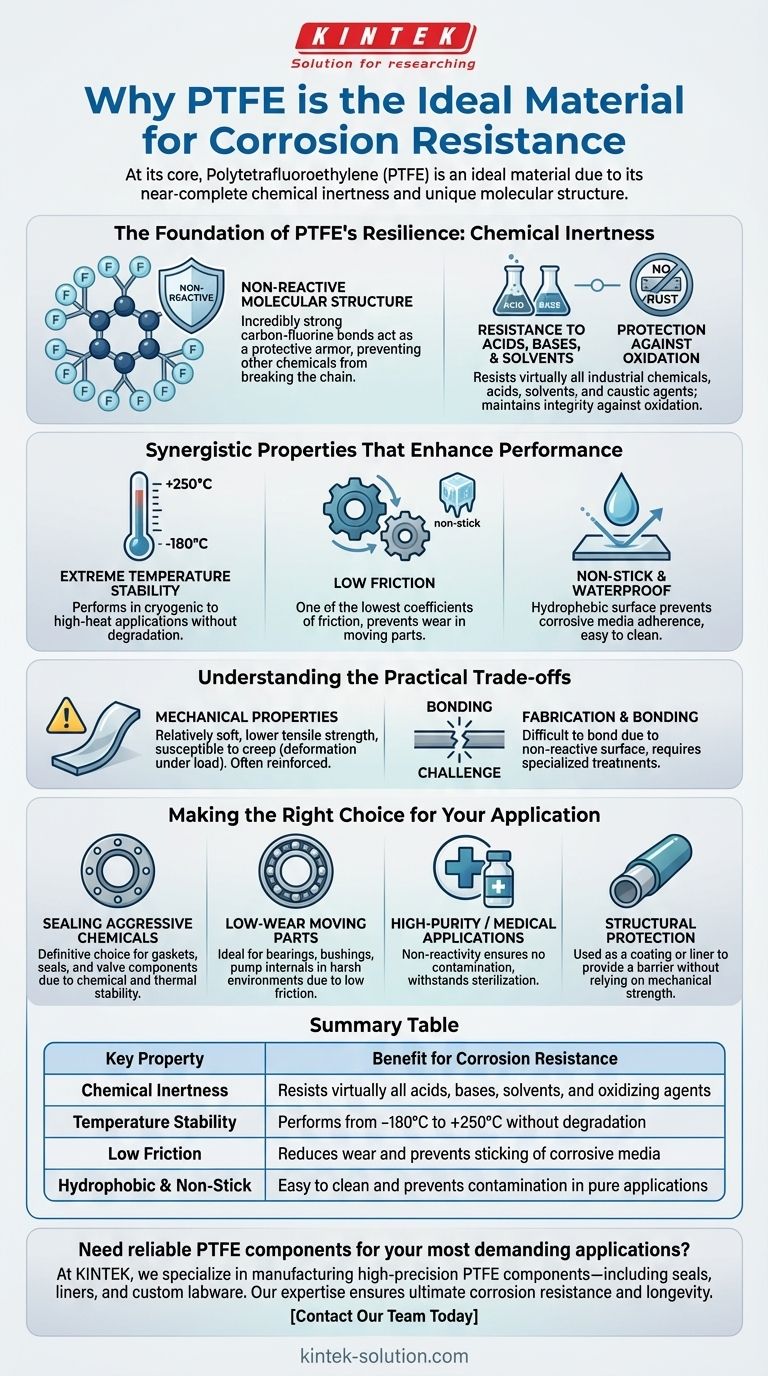

The Foundation of PTFE's Resilience: Chemical Inertness

The primary reason PTFE is specified for harsh environments is its fundamental inability to participate in chemical reactions. This property stems directly from its molecular architecture.

A Non-Reactive Molecular Structure

PTFE consists of a long chain of carbon atoms completely shielded by a helix of fluorine atoms. The carbon-fluorine bond is one of the strongest single bonds in organic chemistry.

This powerful bond acts as a protective armor, preventing other chemicals from breaking the chain and reacting with the material.

Resistance to Acids, Bases, and Solvents

Because of its molecular stability, PTFE exhibits near-universal chemical resistance. It remains unaffected by aggressive acids, powerful bases, and virtually all industrial solvents.

This allows it to be used for seals, linings, and components that are in continuous contact with highly corrosive fluids without swelling, dissolving, or degrading.

Protection Against Oxidation

Many materials fail over time due to oxidation, a common form of chemical corrosion. PTFE is highly resistant to this process.

This property ensures that components made from PTFE maintain their physical integrity and plasticity even after long-term exposure to oxidative environments.

Synergistic Properties That Enhance Performance

While chemical inertness is the central feature, other inherent properties of PTFE work in concert to make it even more effective in practical applications.

Extreme Temperature Stability

PTFE maintains its properties over an extraordinary temperature range, from as low as -180°C to as high as +250°C.

This means its corrosion resistance does not falter in cryogenic applications or high-heat industrial processes, a critical advantage over materials that become brittle or melt.

Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This is its well-known "non-stick" or self-lubricating quality.

In applications with moving parts like bearings or seals, this property prevents wear and heat generation, ensuring the component's longevity in a corrosive system.

Non-Stick and Waterproofing Characteristics

The same properties that make PTFE non-reactive also make it hydrophobic (water-repelling) and non-stick.

This prevents corrosive media from adhering to its surface, providing an additional layer of protection and making it easier to clean, which is critical in medical and food-grade applications.

Understanding the Practical Trade-offs

No material is perfect for every situation. While its chemical and thermal properties are exceptional, it's crucial to understand PTFE's limitations to use it effectively.

Mechanical Properties

Compared to metals or other engineering plastics, PTFE is relatively soft and has lower tensile strength. It can be susceptible to creep, which is deformation under a sustained load.

This means it is often used as a lining or coating or reinforced with other materials (like glass or carbon) in high-load structural applications.

Fabrication and Bonding

The same non-stick, non-reactive properties that make PTFE so valuable also make it very difficult to bond to other surfaces using conventional adhesives.

Specialized surface treatments, like chemical etching, are often required to prepare PTFE for bonding, adding complexity and cost to the manufacturing process.

Making the Right Choice for Your Application

Selecting PTFE is about leveraging its unique combination of properties for a specific goal.

- If your primary focus is sealing aggressive chemicals: PTFE's chemical inertness and temperature stability make it the definitive choice for gaskets, seals, and valve components.

- If your primary focus is low-wear moving parts in a harsh environment: Its low coefficient of friction combined with corrosion resistance is ideal for bearings, bushings, and pump internals.

- If your primary focus is high-purity or medical applications: PTFE's non-reactivity and resistance to sterilization chemicals ensure that it will not contaminate the medium or degrade.

- If your primary focus is protecting a structure from corrosion: Using PTFE as a coating or liner leverages its barrier properties without relying on its limited mechanical strength.

Ultimately, choosing PTFE is a decision to prioritize unparalleled chemical and thermal resilience for critical components where failure is not an option.

Summary Table:

| Key Property | Benefit for Corrosion Resistance |

|---|---|

| Chemical Inertness | Resists virtually all acids, bases, solvents, and oxidizing agents |

| Temperature Stability | Performs from -180°C to +250°C without degradation |

| Low Friction | Reduces wear and prevents sticking of corrosive media |

| Hydrophobic & Non-Stick | Easy to clean and prevents contamination in pure applications |

Need reliable PTFE components for your most demanding applications?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your components provide the ultimate corrosion resistance, temperature stability, and longevity you require.

Whether you need prototypes or high-volume production, contact our team today to discuss how our custom PTFE solutions can protect your critical systems.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How was PTFE discovered and developed? From Lab Accident to Essential High-Performance Polymer

- What is Teflon and what are its alternative names? Understanding PTFE, the Material Behind the Brand

- When was PTFE discovered and developed? The Accidental Invention That Changed Industries

- How does PTFE react to common solvents? Discover Its Near-Total Chemical Immunity

- What are the similarities between PTFE and RPTFE? Unlocking the Core Fluoropolymer Identity