At its core, PTFE's excellence as a wire and cable insulator stems from a unique combination of three properties. It possesses outstanding electrical resistance, can withstand an exceptionally wide range of temperatures, and is almost completely immune to chemical attack. This trifecta ensures signals remain pure and power is delivered safely in environments where other materials would quickly fail.

While many materials can insulate a wire, PTFE is specified when performance and reliability are non-negotiable. Its value is not in being a generic insulator, but in being a definitive solution for high-frequency signals, extreme temperatures, and chemically aggressive environments.

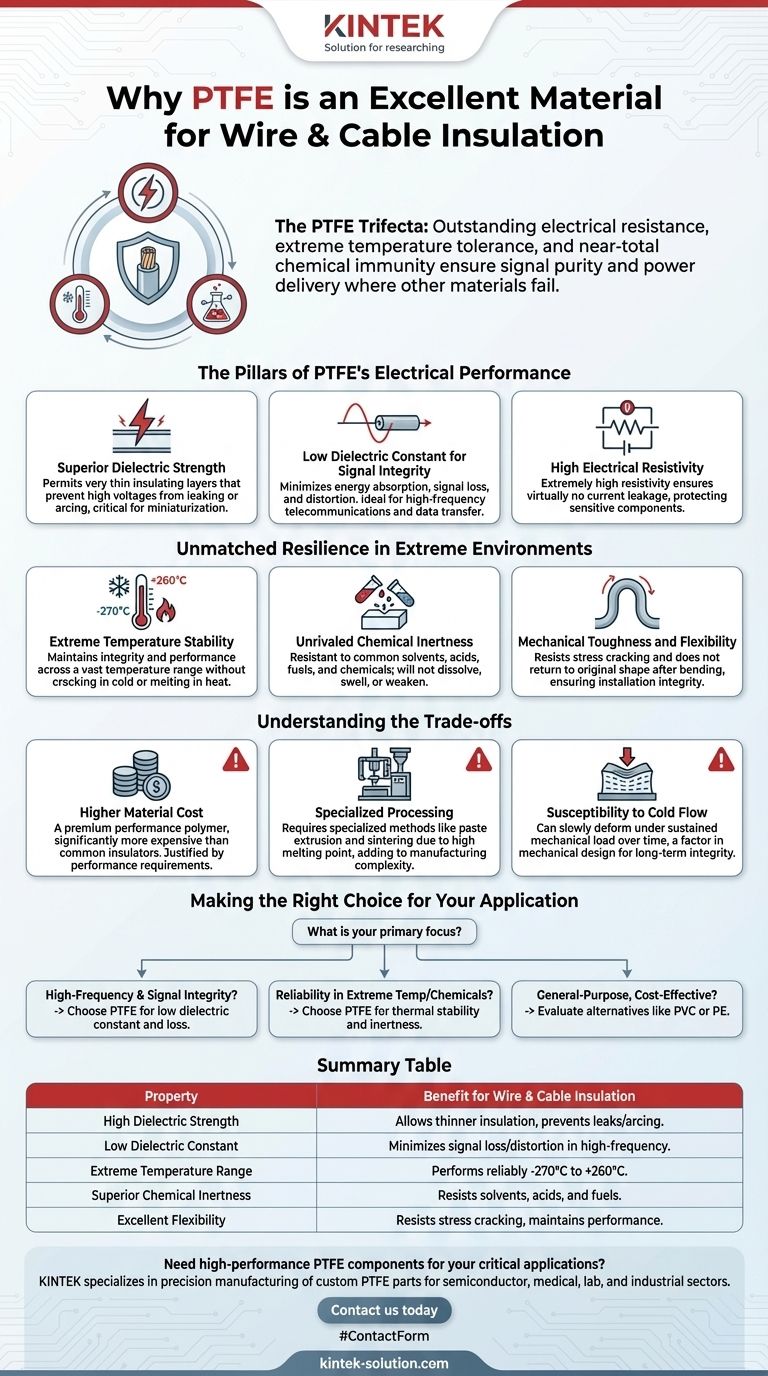

The Pillars of PTFE's Electrical Performance

The primary function of an insulator is to prevent the flow of electricity. PTFE (Polytetrafluoroethylene) accomplishes this with a level of effectiveness that makes it a premium choice for demanding electronic and electrical applications.

Superior Dielectric Strength

Dielectric strength measures a material's ability to withstand a strong electric field without breaking down and allowing current to pass through.

PTFE has a very high dielectric strength. This allows it to be used as a very thin insulating layer while still preventing high voltages from leaking or arcing, which is critical for miniaturizing electronics and creating high-density cables.

Low Dielectric Constant for Signal Integrity

The dielectric constant indicates how much electrical energy a material can store when subjected to an electric field. For high-frequency signal cables, a lower number is always better.

PTFE's low dielectric constant means it absorbs very little energy from the signal passing through the conductor. This minimizes signal loss and distortion, making it an ideal choice for high-frequency applications like coaxial cables used in telecommunications and data transfer.

High Electrical Resistivity

Resistivity measures how strongly a material opposes the flow of electric current. PTFE is one of the best electrical insulators known, possessing extremely high resistivity.

This ensures that current leakage is virtually nonexistent, protecting sensitive components from stray currents and minimizing power loss in a system.

Unmatched Resilience in Extreme Environments

A wire's insulation must protect the conductor not just electrically, but also from the physical world. PTFE's molecular structure gives it a robustness that few other polymers can match.

Extreme Temperature Stability

PTFE maintains its integrity and performance across a vast temperature range, typically cited from -270°C to over 260°C (-454°F to 500°F).

Unlike other plastics, it does not become brittle and crack in cryogenic conditions, nor does it melt or degrade in high-heat applications. This consistency is essential for aerospace, industrial, and military systems.

Unrivaled Chemical Inertness

The carbon-fluorine bonds that make up PTFE are incredibly strong and stable, making the material nearly impervious to all common solvents, acids, fuels, and chemicals.

This property ensures the insulation will not dissolve, swell, or weaken when exposed to aggressive fluids, a common requirement in automotive, chemical processing, and medical device applications.

Mechanical Toughness and Flexibility

PTFE insulation is not subject to "memory," meaning it does not try to return to a previous shape after being bent or flexed. It is also highly resistant to stress cracking.

This ensures that the physical act of installation or the repeated movement of a cable in a dynamic application does not compromise the integrity of the insulation.

Understanding the Trade-offs

No material is perfect for every situation. While PTFE's properties are exceptional, its use comes with practical considerations that are critical for making an informed decision.

Higher Material Cost

PTFE is a premium performance polymer, and its cost reflects that. It is significantly more expensive than common insulators like PVC (Polyvinyl Chloride) or PE (Polyethylene). Its use is typically justified by performance requirements, not budget.

Specialized Processing

PTFE has a very high melting point and viscosity, which means it cannot be processed using conventional melt-extrusion techniques like other thermoplastics. It requires specialized methods like paste extrusion and sintering, which adds to manufacturing complexity and cost.

Susceptibility to Cold Flow

While PTFE is exceptionally flexible, it is a relatively soft material that can be subject to "cold flow," or creep. Under a sustained, concentrated mechanical load (like a tightly clamped terminal), the material can slowly deform over time. This must be accounted for in mechanical designs to ensure long-term connection integrity.

Making the Right Choice for Your Application

Selecting an insulation material requires balancing performance needs with practical constraints. PTFE should be chosen deliberately when its unique advantages solve a specific challenge.

- If your primary focus is high-frequency performance and signal integrity: PTFE's low dielectric constant and low loss factor make it the superior choice to preserve your signal quality.

- If your primary focus is reliability in extreme temperatures or chemical exposure: PTFE's thermal stability and chemical inertness provide a level of protection that commodity plastics cannot offer.

- If your primary focus is a general-purpose, cost-effective application: You should evaluate less expensive alternatives like PVC or PE, as PTFE's capabilities may be unnecessary.

By understanding these distinct characteristics, you can confidently specify PTFE for applications where performance and reliability are paramount.

Summary Table:

| Property | Benefit for Wire & Cable Insulation |

|---|---|

| High Dielectric Strength | Allows for thinner insulation, preventing voltage leaks and arcing. |

| Low Dielectric Constant | Minimizes signal loss and distortion in high-frequency applications. |

| Extreme Temperature Range | Performs reliably from -270°C to +260°C without cracking or melting. |

| Superior Chemical Inertness | Resists virtually all solvents, acids, and fuels, ensuring long-term integrity. |

| Excellent Flexibility | Resists stress cracking and maintains performance when bent or flexed. |

Need high-performance PTFE components for your critical applications?

KINTEK specializes in the precision manufacturing of custom PTFE parts, including wire insulation, seals, liners, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors where material performance is non-negotiable. From prototyping to high-volume production, we deliver the reliability your projects demand.

Contact us today to discuss your specific requirements and see how our expertise can benefit your next project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech