In short, ETFE Teflon is highly valued in aerospace primarily because it combines two critical properties: it is exceptionally lightweight and offers superior corrosion and chemical resistance. This combination allows it to reduce aircraft weight, which lowers fuel consumption, while simultaneously protecting sensitive components from harsh operational environments.

The core challenge in aerospace engineering is finding materials that reduce weight without sacrificing safety or durability. ETFE directly addresses this by providing robust protection against chemicals and degradation in a very low-density package, making it an optimal choice for non-structural components.

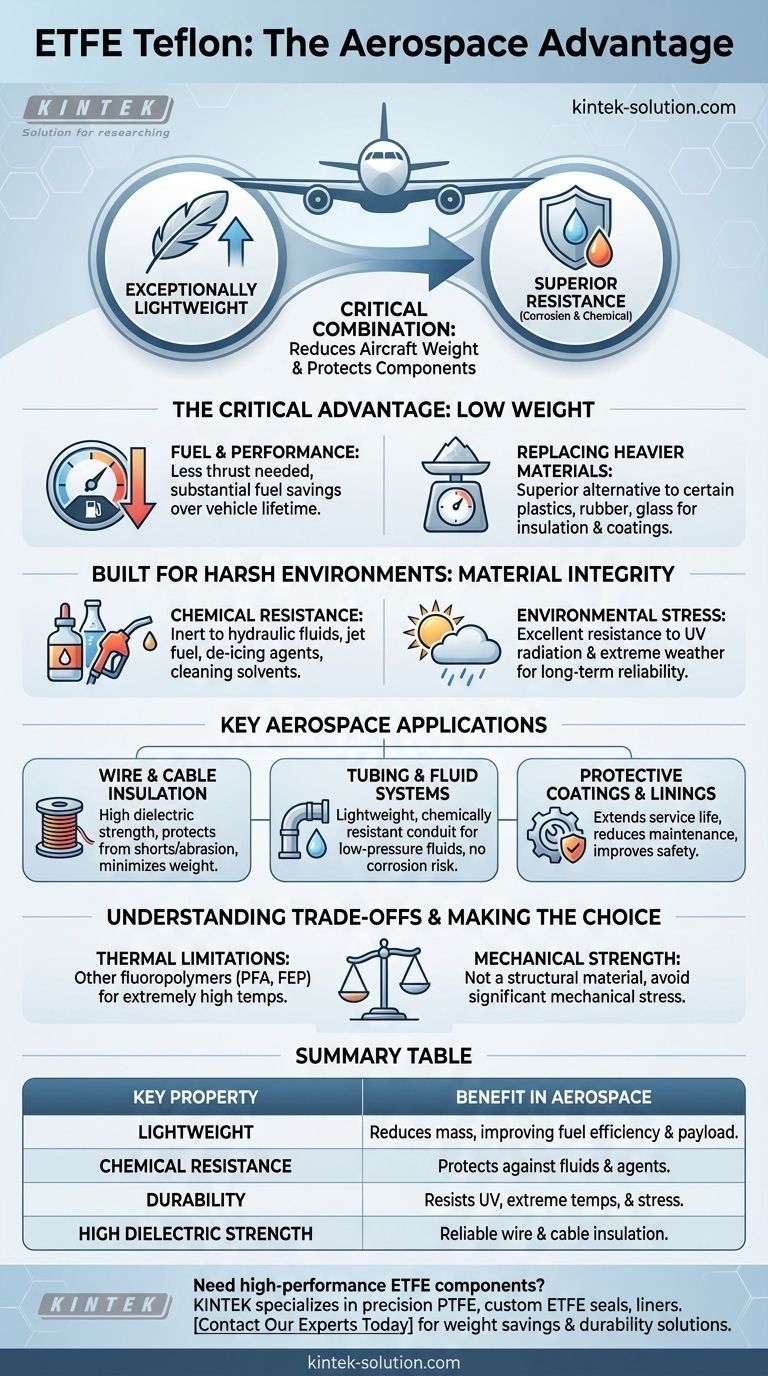

The Critical Advantage: Low Weight

In aerospace, every gram matters. Reducing the overall mass of an aircraft or spacecraft has a direct and significant impact on fuel efficiency, payload capacity, and operational range.

The Impact on Fuel and Performance

A lighter aircraft requires less thrust to achieve and maintain flight, leading to substantial fuel savings over the lifetime of the vehicle. ETFE's low density makes it a superior alternative to heavier materials like certain plastics, rubber, or glass in many applications.

Replacing Heavier Materials

ETFE is often used for wire and cable insulation, tubing, and protective coatings. In these roles, it replaces materials that would add unnecessary weight while still meeting or exceeding performance requirements for insulation and durability.

Built for Harsh Environments: Material Integrity

Aerospace vehicles operate in extreme conditions, from ground-level exposure to chemicals to the temperature and pressure changes of high-altitude flight. A material's ability to withstand these factors is non-negotiable.

Superior Chemical Resistance

ETFE is virtually inert to a wide range of substances common in aerospace, including hydraulic fluids, jet fuel, de-icing agents, and cleaning solvents. This prevents material degradation that could lead to component failure.

Resistance to Environmental Stress

The material also exhibits excellent resistance to UV radiation and extreme weather, which is crucial for any externally-facing components or internal parts near windows. This ensures long-term stability and reliability without embrittlement or breakdown.

Key Aerospace Applications

ETFE's unique properties make it suitable for several specific and critical roles within an aircraft.

Wire and Cable Insulation

This is one of the most significant applications. ETFE's high dielectric strength, flexibility, and light weight make it ideal for insulating the vast network of wiring in an aircraft, protecting it from shorts, abrasion, and chemical exposure while minimizing weight.

Tubing and Fluid Systems

For systems that transport low-pressure fluids or gases, ETFE tubing offers a lightweight and chemically resistant conduit. It ensures the integrity of the fluid path without the risk of corrosion associated with some metal tubing.

Protective Coatings and Linings

ETFE can be applied as a coating to protect metal or composite parts from corrosive elements. This extends the service life of critical components, reducing maintenance costs and improving safety.

Understanding the Trade-offs

No material is perfect for every situation, and it's important to understand where ETFE fits.

Thermal Limitations

While ETFE has a broad operating temperature range, other fluoropolymers like PFA or FEP may offer superior performance in extremely high-temperature environments. The specific thermal demands of the application must be considered.

Mechanical Strength

ETFE is a tough and durable polymer, but it is not a structural material. It does not possess the load-bearing strength of metal alloys or advanced composites and should not be used in applications where it would be subjected to significant mechanical stress.

Making the Right Choice for Your Goal

Selecting the correct material requires a clear understanding of your primary engineering objective.

- If your primary focus is weight reduction in electrical systems: ETFE is a top-tier choice for wire and cable insulation due to its excellent dielectric properties and low density.

- If your primary focus is protecting components from chemical exposure: ETFE's broad chemical inertness makes it ideal for tubing, seals, and protective coatings in harsh environments.

- If your primary focus is high structural strength: You must look to aerospace-grade metal alloys or carbon fiber composites, potentially using ETFE as a protective coating.

Ultimately, choosing ETFE is a strategic decision to enhance durability and efficiency where high strength is not the primary requirement.

Summary Table:

| Key Property | Benefit in Aerospace |

|---|---|

| Lightweight | Reduces aircraft mass, improving fuel efficiency and payload capacity. |

| Chemical Resistance | Protects against jet fuel, hydraulic fluids, and de-icing agents. |

| Durability | Resists UV radiation, extreme temperatures, and environmental stress. |

| High Dielectric Strength | Ideal for reliable wire and cable insulation. |

Need high-performance ETFE components for your aerospace project? KINTEK specializes in manufacturing precision PTFE components, including custom ETFE seals, liners, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors with expertise in custom fabrication from prototypes to high-volume orders. Let us help you achieve optimal weight savings and durability. Contact our experts today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the general material properties of PTFE? Discover Its Extreme Chemical & Thermal Resistance

- What are the advantages of PTFE over Polyethylene Terephthalate (PET)? Key Benefits for Demanding Applications

- Which industries commonly use PTFE plastic? A Guide to Its Critical Applications

- Why is PTFE known as a low-friction material? Unlock Superior Performance & Durability

- How is PTFE used in pharmaceutical and medical applications? Essential for Safety & Efficiency

- What construction applications benefit from PTFE's properties? Solve Critical Engineering Challenges

- What are the material properties of PTFE? Master Extreme Performance for Demanding Applications

- What are some applications of PTFE due to its properties? Discover Its Versatility in Demanding Industries