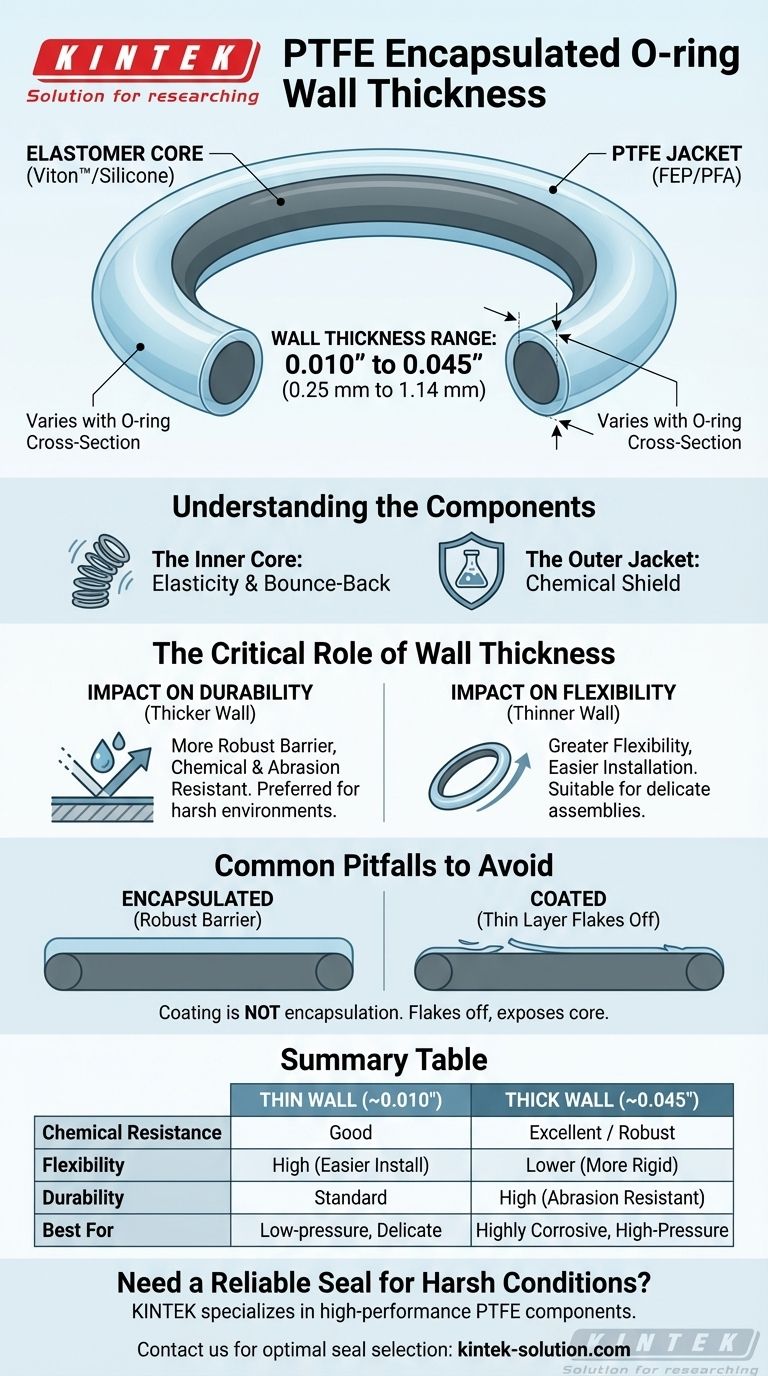

The wall thickness for the PTFE (FEP/PFA) encapsulation on an O-ring typically ranges from 0.010 to 0.045 inches (approximately 0.25 mm to 1.14 mm). This thickness is not a single value but varies depending on the cross-sectional diameter of the O-ring itself, with larger O-rings requiring a thicker jacket to ensure complete and durable coverage.

An encapsulated O-ring is a composite seal that combines the superior chemical resistance of a solid PTFE jacket with the flexibility and memory of an inner elastomer core. The thickness of this jacket is the critical factor that balances chemical impermeability against the mechanical performance needed for a reliable seal.

Understanding the Components

A PTFE encapsulated O-ring is engineered to solve a specific problem: creating a seal that can withstand harsh chemicals while remaining elastic enough to function effectively. This is achieved through a two-part construction.

The Inner Core: The Source of Elasticity

The core of the O-ring is made from a traditional elastomer. This core provides the flexibility and "bounce-back" (compression set resistance) necessary for the O-ring to create and maintain a tight seal.

The two most common core materials are:

- Viton™ (FKM): Chosen for its excellent resistance to high temperatures and a broad range of chemicals.

- Silicone (VMQ): Selected for its wider temperature range, especially for low-temperature flexibility.

The Outer Jacket: The Chemical Shield

The core is completely enclosed in a seamless jacket of PTFE resin, typically FEP (Fluorinated Ethylene Propylene) or PFA (Perfluoroalkoxy). This outer layer is what comes into contact with the application media.

This encapsulation provides the near-universal chemical inertness that PTFE is known for, protecting the more vulnerable elastomer core from aggressive fluids and gases.

The Critical Role of Wall Thickness

The specified range of 0.010 to 0.045 inches is directly tied to the O-ring's overall size. A small, thin O-ring will have an encapsulation on the lower end of this range, while a large O-ring with a thick cross-section will require a heavier wall.

Impact on Durability

A thicker jacket provides a more robust barrier against chemical attack and physical abrasion. In highly corrosive environments or high-pressure applications, a thicker wall is often preferred for long-term reliability.

Impact on Flexibility

The PTFE jacket is inherently more rigid than the elastomer core. A thicker wall increases this rigidity, which can make the O-ring harder to install and may require more force to achieve a proper seal. For applications requiring greater flexibility, a thinner wall is more suitable.

Common Pitfalls to Avoid

Understanding the distinction between an encapsulated O-ring and other sealing options is crucial to prevent application failure.

Encapsulated vs. Coated O-rings

These two are not the same. A PTFE-coated O-ring has only a very thin layer of PTFE applied to the surface, almost like a lubricant.

This coating can easily flake off or wear away, especially in dynamic applications. A coating offers temporary lubricity but does not provide the robust chemical barrier of a true encapsulation. Once the coating fails, the elastomer is fully exposed.

Compression Set Limitations

While the elastomer core provides good compression set resistance, the rigid PTFE jacket can be permanently deformed (creased) if over-compressed. This is a primary reason these seals are often recommended for static applications over dynamic ones.

Making the Right Choice for Your Goal

Selecting the appropriate encapsulation requires balancing chemical needs with mechanical constraints.

- If your primary focus is maximum chemical resistance: Opt for an encapsulated O-ring with a wall thickness on the higher end of the spectrum suitable for your O-ring's cross-section.

- If your primary focus is sealing in a low-pressure or delicate assembly: Ensure the wall thickness is not excessive, as a more flexible seal will perform better with lower compressive force.

- If your primary focus is preventing process contamination: A seamless encapsulated O-ring is an excellent choice, as it eliminates the risk of the flaking associated with simple PTFE coatings.

Ultimately, choosing an encapsulated O-ring is a strategic decision to prevent seal failure in environments where standard elastomers cannot survive.

Summary Table:

| Factor | Thin Wall (~0.010 in) | Thick Wall (~0.045 in) |

|---|---|---|

| Chemical Resistance | Good | Excellent / Robust |

| Flexibility | High (easier installation) | Lower (more rigid) |

| Durability | Standard | High (abrasion resistant) |

| Best For | Low-pressure, delicate assemblies | Highly corrosive or high-pressure environments |

Need a Reliable Seal for Harsh Conditions?

PTFE encapsulated O-rings are a precision component, and the correct wall thickness is critical for your application's success. At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom encapsulated O-rings for the semiconductor, medical, laboratory, and industrial sectors.

We ensure precision production and offer custom fabrication from prototypes to high-volume orders, guaranteeing a perfect balance of chemical resistance and mechanical performance for your specific needs.

Let our experts help you select the optimal seal. Contact KINTEK today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability