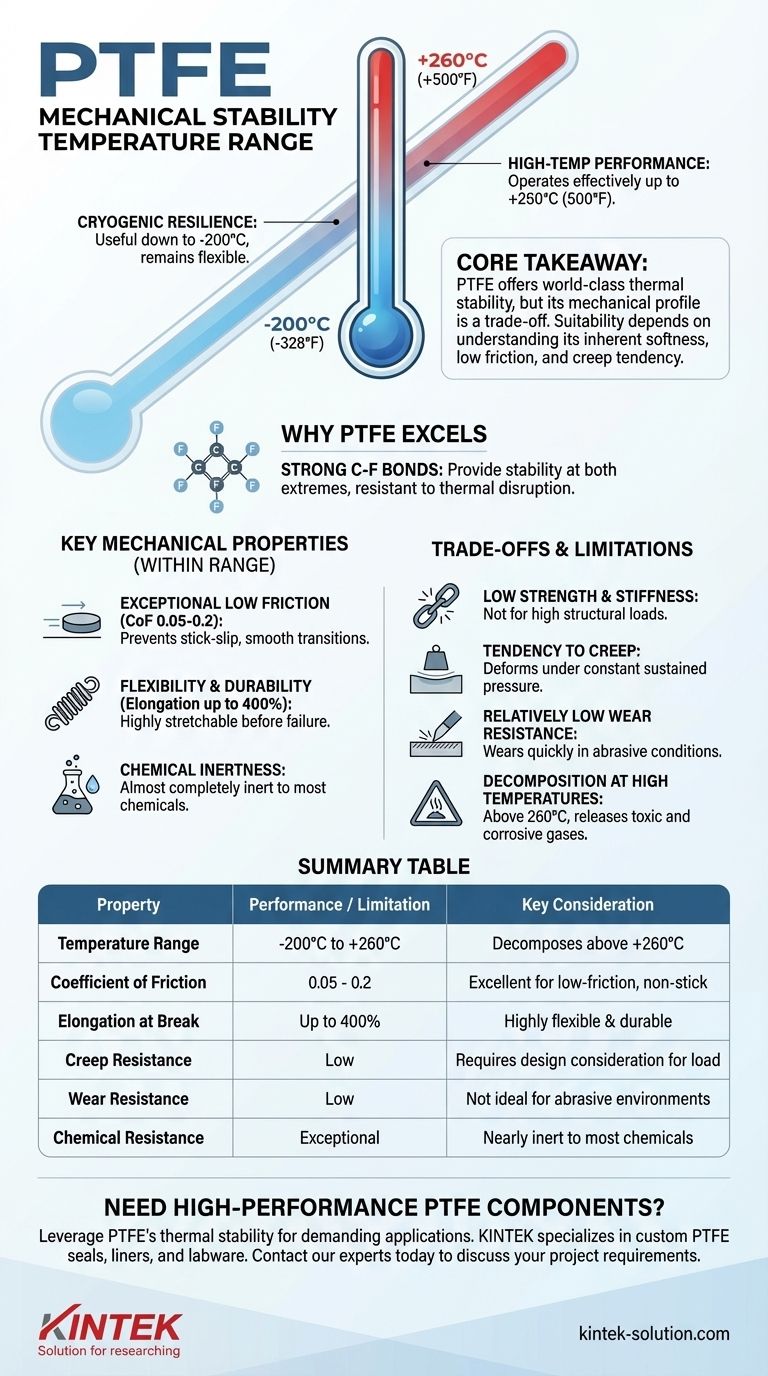

The established temperature range for Polytetrafluoroethylene (PTFE) mechanical stability is exceptionally wide, spanning from -200°C (-328°F) to +260°C (+500°F). Within this vast window, PTFE maintains its unique combination of properties, including flexibility and extreme chemical inertness. However, exceeding this range can lead to decomposition and the release of hazardous gases.

The core takeaway is that while PTFE offers world-class thermal stability, its mechanical profile is one of specific trade-offs. Its suitability depends less on temperature alone and more on understanding its inherent softness, low friction, and tendency to deform under sustained load.

Why PTFE Excels in Extreme Temperatures

The remarkable thermal performance of PTFE is not accidental; it is a direct result of its unique molecular structure. This structure provides stability at both cryogenic and high-heat conditions.

The Role of Carbon-Fluorine Bonds

The foundation of PTFE's stability lies in its strong carbon-fluorine bonds. These bonds are exceptionally stable and create a tight, protective sheath of fluorine atoms around the carbon backbone. This structure is highly resistant to being disrupted by thermal energy.

High-Temperature Performance

PTFE operates effectively up to +260°C (+500°F). While its technical melting point is higher, around 327°C, its mechanical properties begin to degrade before that point, making 260°C the practical upper limit for most applications.

Cryogenic Resilience

At the other extreme, PTFE remains useful down to -200°C (-328°F). Unlike many polymers that become brittle and fracture at such low temperatures, PTFE retains a useful degree of flexibility and toughness.

Key Mechanical Properties Within the Operating Range

Temperature stability is only part of the story. To use PTFE effectively, you must understand its distinct mechanical characteristics within its safe operating range.

Exceptional Low Friction

PTFE is famous for its very low coefficient of friction (0.05-0.2). Critically, its static and dynamic friction coefficients are nearly identical, which prevents "stick-slip" behavior and allows for exceptionally smooth transitions from a resting to a moving state.

Flexibility and Durability

While not a rigid material, PTFE is durable and flexible. It exhibits a high elongation at break (up to 400%), meaning it can stretch significantly before failing. It also possesses good impact resistance for a soft polymer.

Chemical Inertness

Complementing its thermal stability, PTFE is almost completely inert to most chemicals. This is due to the same stable carbon-fluorine bonds, making it a premier choice for seals and linings in corrosive environments.

Understanding the Trade-offs and Limitations

No material is perfect, and PTFE's strengths come with clear limitations. Acknowledging these trade-offs is crucial for successful engineering design.

Low Strength and Stiffness

PTFE is a relatively soft material with low tensile strength and stiffness (Young's modulus). It should not be used in applications requiring high structural load-bearing capacity.

Tendency to Creep

One of the most significant limitations of PTFE is creep. Under constant, sustained pressure, the material will slowly and permanently deform. This can be a critical failure point in sealing applications if not properly managed in the design.

Relatively Low Wear Resistance

Despite its low friction, the softness of PTFE results in low wear resistance in abrasive conditions. It can be worn away quickly compared to harder polymers or metals.

Decomposition at High Temperatures

It is critical to respect the upper temperature limit. When heated above its operating range, PTFE does not simply melt; it decomposes into toxic and corrosive gases, posing a significant safety hazard.

Making the Right Choice for Your Application

To determine if PTFE is the correct material, map its unique profile to the primary goal of your project.

- If your primary focus is low-friction sliding at extreme temperatures: PTFE is an excellent choice for seals, bearings, and non-stick coatings where the mechanical load is not excessive.

- If your primary focus is high structural strength or rigidity: You should consider alternative materials, as PTFE's softness and tendency to creep make it unsuitable for high-load applications.

- If your primary focus is chemical resistance across a wide thermal range: PTFE is nearly unmatched, but you must engineer your design to account for its inherent mechanical limitations.

Understanding these properties allows you to leverage PTFE's unique strengths while respecting its inherent limitations.

Summary Table:

| Property | Performance / Limitation | Key Consideration |

|---|---|---|

| Temperature Range | -200°C to +260°C (-328°F to +500°F) | Decomposes into toxic gases above 260°C |

| Coefficient of Friction | 0.05 - 0.2 | Excellent for low-friction, non-stick applications |

| Elongation at Break | Up to 400% | Highly flexible and durable |

| Creep Resistance | Low | Can deform under sustained load; requires design consideration |

| Wear Resistance | Low | Not ideal for highly abrasive environments |

| Chemical Resistance | Exceptional | Nearly inert to most chemicals |

Need High-Performance PTFE Components?

Leverage PTFE's unique thermal stability and chemical inertness for your most demanding applications. KINTEK specializes in the precision manufacturing of custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We understand the critical balance between PTFE's advantages and its mechanical limitations. Our expertise ensures your components are designed and fabricated to perform reliably, whether you need prototypes or high-volume production.

Contact our experts today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE resist chemical attacks? The Science Behind Its Unmatched Chemical Inertness

- What are common uses of PTFE in laboratory and industrial settings? Unlock Chemical and Thermal Resistance

- Why is PTFE known as a low-friction material? Unlock Superior Performance & Durability

- How is PTFE utilized in the electronics and electrical industry? Essential for High-Frequency & Harsh Environments

- How is Teflon utilized in the electronics industry? Ensuring Signal Integrity and Reliability

- What types of clothing incorporate Teflon? Discover High-Performance Protective Apparel

- What are the key characteristics of PTFE's molecular structure? Unlock the Power of the Fluorine Sheath

- How is PTFE manufactured? Unlocking the Secrets of a High-Performance Polymer