The specific gravity of Polytetrafluoroethylene (PTFE) consistently falls within a narrow and reliable range. This value is typically between 2.10 and 2.20 g/cc, making it one of the denser engineering polymers. This density is a direct result of its unique molecular structure, which is also the source of its most famous properties.

While its specific gravity is a straightforward figure, it is a direct consequence of PTFE's highly stable, fluorine-based molecular structure. This structure is the root cause of its most valued traits: extreme chemical inertness, a very low coefficient of friction, and high-temperature resistance.

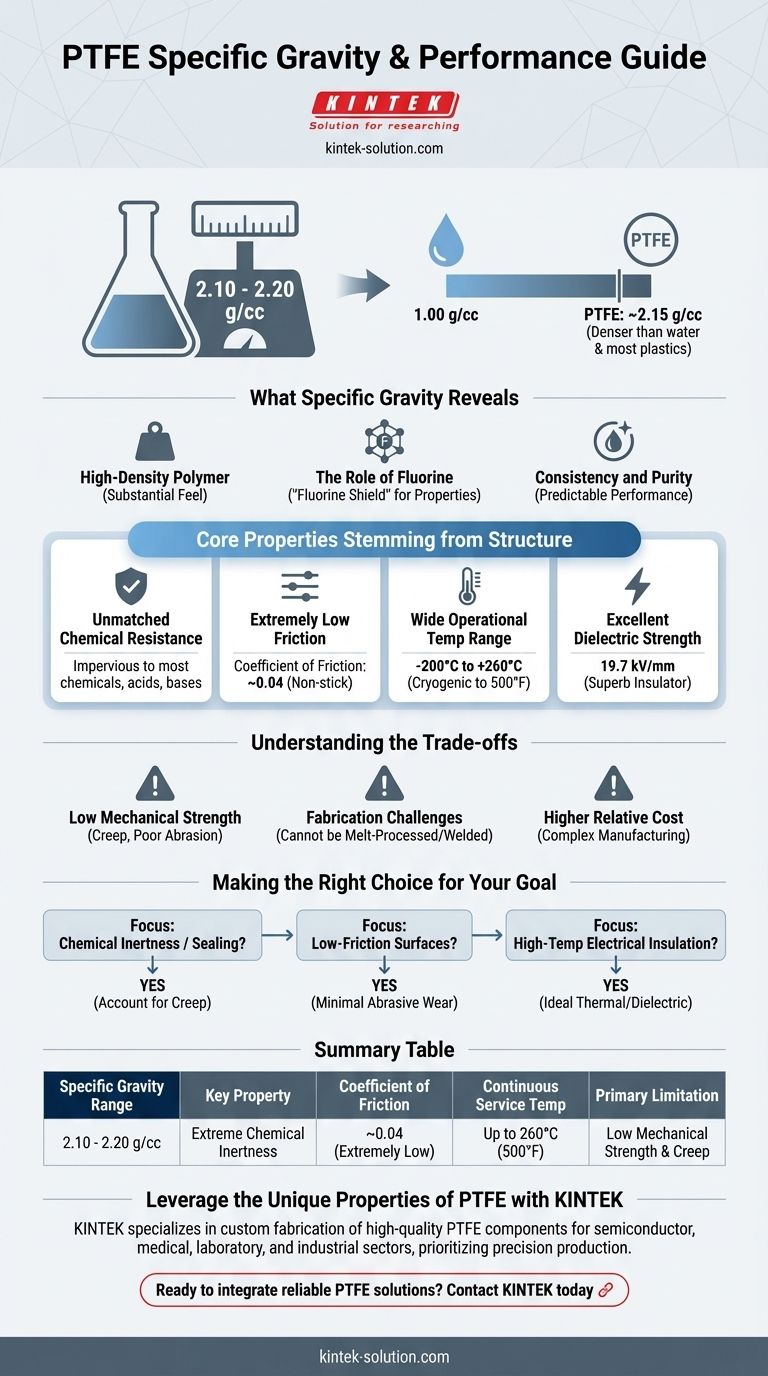

What Specific Gravity Reveals About PTFE

Specific gravity, a measure of density relative to water, is more than just a number on a data sheet. For PTFE, it tells a story about its fundamental composition and why it behaves the way it does.

A High-Density Polymer

At 2.10 to 2.20 g/cc, PTFE is significantly denser than many common plastics like Polyethylene (around 0.95 g/cc). This contributes to its substantial, high-quality feel in finished parts.

The Role of Fluorine

The high density is primarily due to the heavy fluorine atoms that completely surround the carbon backbone of the polymer chain. This "fluorine shield" is the key to almost all of PTFE's signature characteristics.

Consistency and Purity

The tight specific gravity range indicates a very consistent and pure material. For engineers and designers, this translates to predictable performance and reliability in critical applications.

Core Properties Stemming from Its Structure

The same molecular structure that defines PTFE's density also grants it a unique combination of high-performance properties.

Unmatched Chemical Resistance

The strong carbon-fluorine bonds are exceptionally stable and non-reactive. This makes PTFE virtually impervious to attack from almost all chemicals, acids, and bases.

Extremely Low Friction

PTFE has the lowest coefficient of friction of any known solid, with a dynamic value around 0.04. This is what creates its famous non-stick surface, ideal for coatings, bearings, and seals.

Wide Operational Temperature Range

PTFE performs reliably across a vast temperature spectrum. It remains useful at cryogenic temperatures and can be used continuously at up to 260°C (500°F), with a melting point over 320°C.

Excellent Dielectric Strength

As a superb electrical insulator, PTFE has a high dielectric strength (19.7 kV/mm) and a low dielectric constant. This makes it a preferred material for high-frequency cables and circuit boards.

Understanding the Trade-offs

No material is perfect. While PTFE's properties are extraordinary, it's crucial to understand its limitations for successful implementation.

Low Mechanical Strength

PTFE is a relatively soft material. It is susceptible to creep (cold flow) under sustained load and has poor abrasion resistance compared to other engineering polymers.

Fabrication Challenges

PTFE cannot be melt-processed like typical thermoplastics. It also cannot be solvent-welded or cemented, which requires mechanical fastening or specialized surface treatments for bonding.

Higher Relative Cost

The complex manufacturing process and unique properties of PTFE mean it carries a higher cost than commodity plastics. Its use is typically reserved for applications where its specific advantages are a necessity.

Making the Right Choice for Your Goal

Selecting a material requires balancing its strengths against your application's demands. Use these points as a guide for deciding if PTFE is the correct choice.

- If your primary focus is chemical inertness or sealing: PTFE is an unparalleled choice, but you must account for its tendency to creep under constant pressure.

- If your primary focus is low-friction surfaces: Its exceptionally low coefficient of friction is ideal for bearings or non-stick coatings, provided the abrasive wear is minimal.

- If your primary focus is high-temperature electrical insulation: PTFE's combination of thermal stability and excellent dielectric properties makes it a top-tier material.

Understanding these interconnected properties—from density to performance trade-offs—is the key to successfully leveraging PTFE in your designs.

Summary Table:

| Property | Value / Characteristic |

|---|---|

| Specific Gravity Range | 2.10 - 2.20 g/cc |

| Key Property | Extreme Chemical Inertness |

| Coefficient of Friction | ~0.04 (Extremely Low) |

| Continuous Service Temp | Up to 260°C (500°F) |

| Primary Limitation | Low Mechanical Strength & Creep |

Leverage the Unique Properties of PTFE for Your Application

Understanding PTFE's specific gravity and the high-performance properties it indicates is the first step. The next is sourcing precision-manufactured components that meet your exact requirements.

KINTEK specializes in the custom fabrication of high-quality PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We prioritize precision production to ensure your parts deliver on PTFE's promise of chemical resistance, low friction, and thermal stability.

Ready to integrate reliable PTFE solutions into your design? Contact KINTEK today to discuss your project, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability