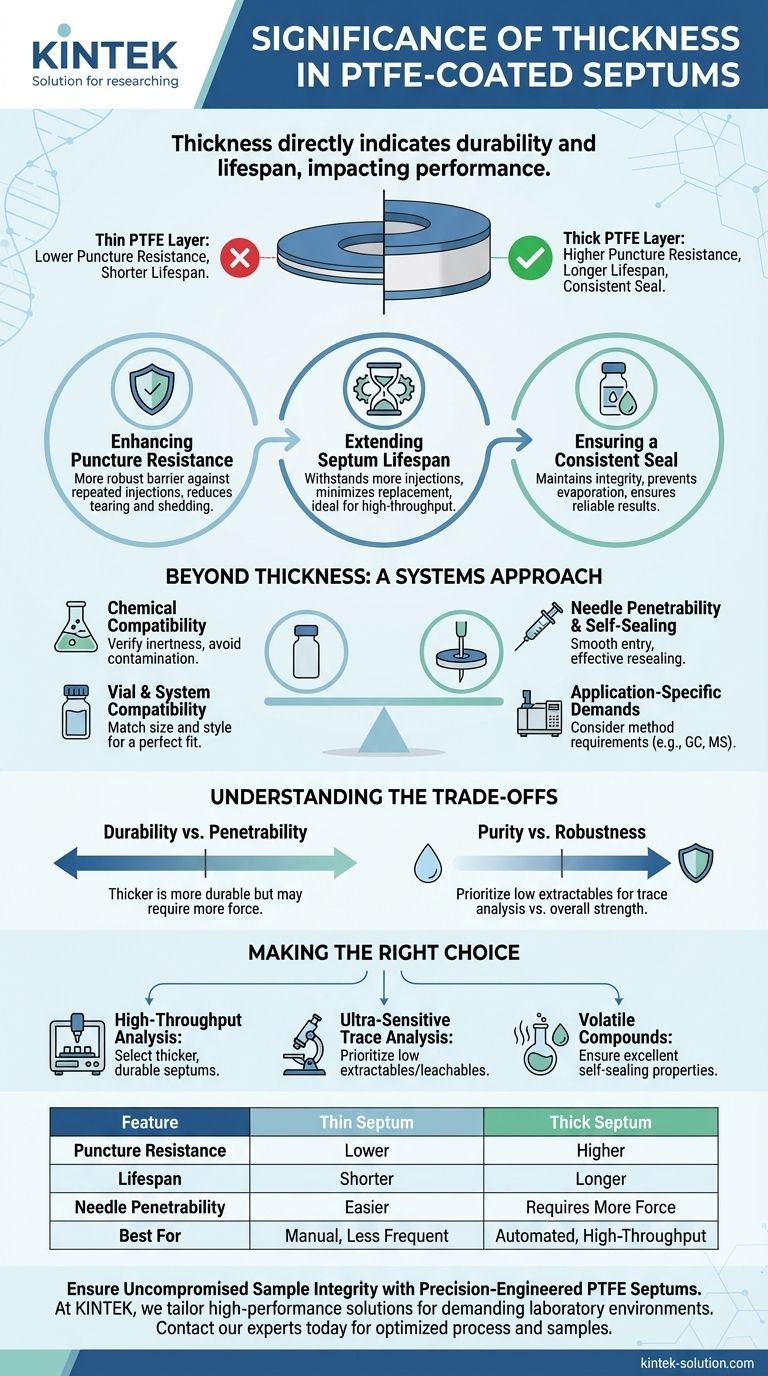

The thickness of a PTFE-coated septum is a direct indicator of its durability and lifespan. A thicker PTFE layer provides greater puncture resistance against repeated needle injections, which extends the septum's usable life and reduces the risk of sample contamination. This ensures more consistent and reliable performance, especially in automated, high-throughput environments.

While a thicker septum enhances durability, the optimal choice is not based on thickness alone. It requires balancing puncture resistance against other critical factors like needle penetrability, chemical compatibility, and the specific demands of your analytical method.

The Core Function of Septum Thickness

The primary role of the PTFE/silicone septum is to create an inert, leak-proof seal that protects the sample. Thickness directly impacts how well it performs this role over time.

Enhancing Puncture Resistance

The PTFE coating serves as the first line of defense against the needle. A thicker layer provides a more robust barrier, significantly reducing the chance of the septum tearing or shedding particles into the vial upon injection.

Extending Septum Lifespan

Because a thicker coating is more resistant to damage, it can withstand a greater number of injections before failing. This is crucial in autosampler sequences, as it minimizes the need for frequent replacement and reduces the risk of failed runs due to a compromised seal.

Ensuring a Consistent Seal

A septum that remains intact after an injection is essential for maintaining sample integrity. The elasticity of the silicone layer allows the septum to reseal, but a durable PTFE coating prevents the formation of a permanent hole, which would lead to the evaporation of volatile compounds.

Beyond Thickness: A Systems Approach to Septum Selection

Thickness is a critical variable, but it works in concert with other properties. A holistic view is necessary for proper selection.

Chemical Compatibility

The septum must be inert and not react with your sample or solvent. PTFE is highly resistant to a wide range of chemicals, but you must always verify its compatibility with the specific compounds in your laboratory to prevent sample contamination or septum degradation.

Vial and System Compatibility

A perfect seal is impossible if the septum does not fit the vial correctly. It is essential to match the septum's size, style, and configuration to the specific vial type being used. An improper fit will cause leaks, regardless of the septum's thickness or quality.

Needle Penetrability and Self-Sealing

The septum must allow for smooth needle entry without causing damage to the needle or "coring" (pushing a piece of the septum into the vial). After the needle is withdrawn, the septum's self-sealing properties are critical for preventing leaks and sample loss.

Application-Specific Demands

Different analytical methods have unique requirements. For gas chromatography (GC), minimizing sample loss from evaporation is key. For highly sensitive analyses like mass spectrometry, using septums with minimal extractables and leachables is vital to avoid analytical interference.

Understanding the Trade-offs

Choosing the ideal septum often involves balancing competing factors. What provides an advantage in one area can be a liability in another.

Durability vs. Penetrability

A thicker, more durable septum offers superior puncture resistance. However, it may also require more force for the needle to penetrate, potentially leading to bent needles on autosamplers or incomplete injections if the system is not properly calibrated.

Purity vs. Robustness

While PTFE is inert, all materials contain trace levels of impurities. For ultra-sensitive trace analysis, the primary concern is finding a septum certified for the lowest possible levels of extractables and leachables, which may take precedence over selecting the thickest or most durable option.

Making the Right Choice for Your Application

Ultimately, your goal determines the best septum. Consider your primary objective to guide your selection.

- If your primary focus is high-throughput analysis: Select a thicker, more durable septum to minimize replacement frequency and ensure consistent performance across many automated injections.

- If your primary focus is ultra-sensitive trace analysis: Prioritize a septum certified for low extractables and leachables to avoid interference with your results, balancing this need with sufficient durability.

- If your primary focus is working with volatile compounds: Ensure the septum offers excellent self-sealing properties to prevent sample evaporation and maintain accurate concentrations.

By understanding how thickness interacts with other key properties, you can confidently select a septum that safeguards the integrity of every analysis.

Summary Table:

| Feature | Thin Septum | Thick Septum |

|---|---|---|

| Puncture Resistance | Lower | Higher |

| Lifespan (Number of Injections) | Shorter | Longer |

| Needle Penetrability | Easier | Requires More Force |

| Best For | Manual injections, less frequent use | Automated, high-throughput systems |

Ensure Uncompromised Sample Integrity with Precision-Engineered PTFE Septums

Choosing the right septum is critical for reliable results. At KINTEK, we specialize in manufacturing high-performance PTFE components, including septums tailored for the demanding environments of semiconductor, medical, laboratory, and industrial applications.

We understand that the perfect balance of thickness, chemical compatibility, and self-sealing properties is unique to your method. Whether you need a standard solution or a custom-fabricated prototype for high-throughput GC/MS analysis, our expertise ensures you get a septum that protects your samples and your data.

Let us help you optimize your analytical process. Contact our experts today to discuss your specific requirements and receive a sample.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components