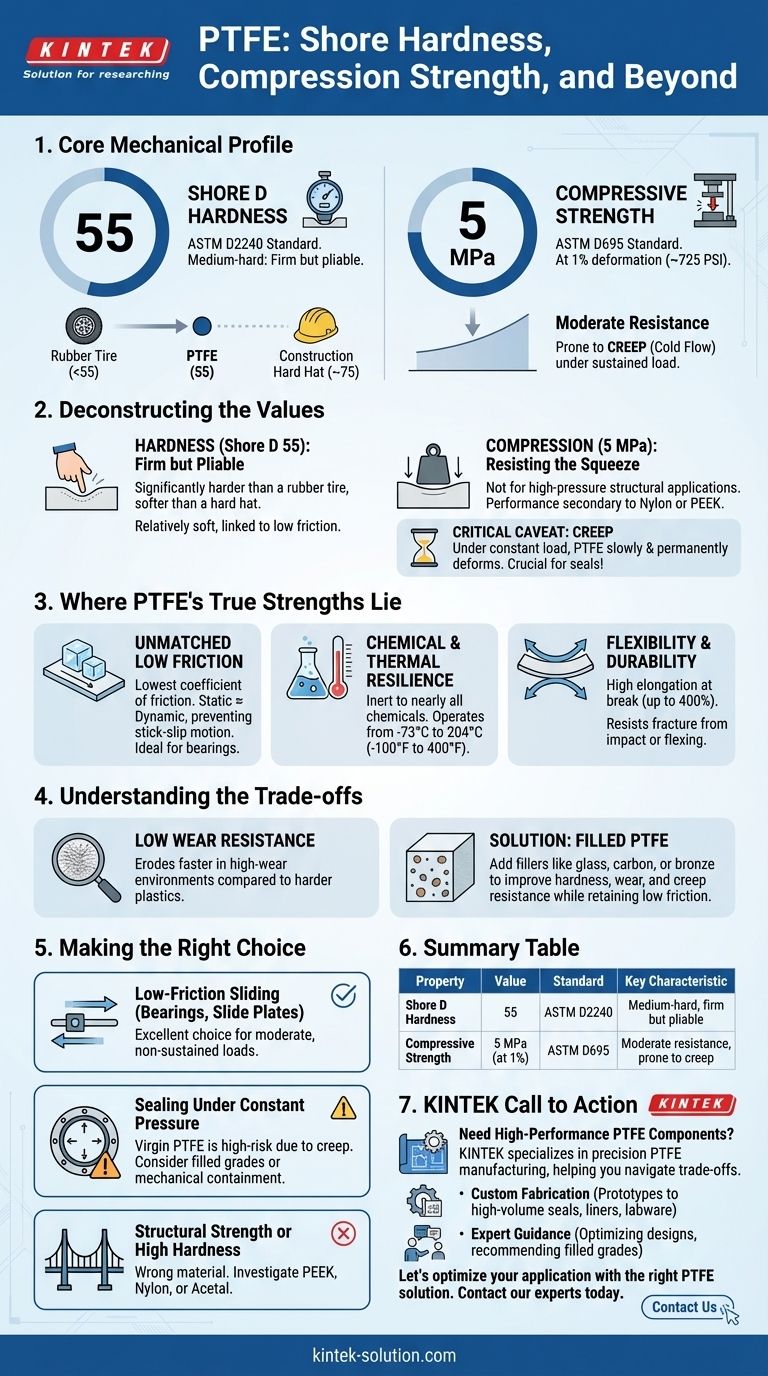

To be precise, Polytetrafluoroethylene (PTFE) has a Shore D hardness of 55 when measured by the ASTM D2240 standard. Its compressive strength is 5 MPa at a 1% deformation, as determined by the ASTM D695 standard. These values place PTFE as a relatively soft polymer with moderate resistance to compression.

While its hardness and compressive strength are modest, PTFE is rarely chosen for these properties alone. Its true value lies in its unparalleled low friction, exceptional chemical inertness, and wide operating temperature range, which often compensate for its mechanical limitations.

Deconstructing PTFE's Mechanical Profile

Understanding the raw numbers for hardness and compression is only the first step. To select the right material, you must understand what these values mean in a practical, real-world context.

Hardness (Shore D 55): Firm but Pliable

The Shore D 55 rating places PTFE in the medium-hard range for plastics. It is significantly harder than a rubber tire but softer than a material like a construction hard hat (which is typically around Shore D 75).

This means PTFE is firm to the touch but can be scratched or indented without extreme force. This relative softness is directly linked to its signature low-friction characteristics.

Compression Strength (5 MPa): Resisting the Squeeze

A compressive strength of 5 MPa means it takes approximately 725 PSI of pressure to compress a piece of PTFE by just 1%.

While it can withstand moderate compressive loads, it is not designed for high-pressure structural applications. Its performance here is secondary to materials like Nylon or PEEK.

The Creep Factor: A Critical Design Consideration

The most important caveat to PTFE's compressive strength is its tendency to creep, also known as cold flow.

Under a constant, sustained load, PTFE will slowly and permanently deform over time. This is a critical failure mode to consider, especially in gasket or sealing applications where consistent pressure is required.

Where PTFE's True Strengths Lie

If PTFE isn't exceptionally hard or strong, why is it so widely used in demanding applications? Its value comes from a unique combination of other elite properties.

Unmatched Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice.

Crucially, its static and dynamic friction coefficients are nearly identical. This prevents "stick-slip" motion, ensuring smooth, consistent movement from a complete stop, which is vital for bearings and sliding components.

Chemical and Thermal Resilience

PTFE is almost completely inert, resisting nearly all industrial chemicals and solvents. It also maintains its properties over an incredibly broad temperature range, from -73°C to 204°C (-100°F to 400°F).

Flexibility and Durability

Despite its moderate strength, PTFE is not brittle. It has a very high elongation at break (up to 400%), meaning it can bend and flex significantly before failing. This makes it a durable material that resists fracture from impact or flexing.

Understanding the Trade-offs

No material is perfect. Objectively, PTFE has clear limitations that must be respected in any design.

Low Wear Resistance

The same properties that give PTFE its low friction also contribute to its relatively low resistance to abrasive wear. In high-wear environments, it can be eroded more quickly than harder plastics.

The Challenge of Creep (Cold Flow)

As mentioned, creep is PTFE's primary mechanical weakness. If your application involves a constant compressive load, virgin PTFE may deform out of tolerance, causing seals to leak or components to loosen.

Enhancement with Fillers

To overcome these weaknesses, filled PTFE grades are often used. Adding materials like glass, carbon, or bronze can dramatically improve hardness, wear resistance, and creep resistance while retaining much of PTFE's low-friction character.

Making the Right Choice for Your Application

Use these guidelines to determine if PTFE is the correct material for your specific goal.

- If your primary focus is low-friction sliding: PTFE is an exceptional choice for bearings, slide plates, or non-stick liners where the compressive load is moderate and not sustained indefinitely.

- If your primary focus is sealing under constant pressure: Virgin PTFE is a high-risk choice due to creep; strongly consider a filled PTFE grade or a seal design that mechanically contains the material.

- If your primary focus is structural strength or high hardness: PTFE is the wrong material; you should investigate more robust engineering polymers like PEEK, Nylon, or Acetal.

Choose PTFE when you need its elite combination of slickness, chemical stability, and temperature resistance, not for its raw mechanical strength.

Summary Table:

| Property | Value | Standard | Key Characteristic |

|---|---|---|---|

| Shore D Hardness | 55 | ASTM D2240 | Medium-hard, firm but pliable |

| Compressive Strength | 5 MPa (at 1% deformation) | ASTM D695 | Moderate resistance, prone to creep |

Need High-Performance PTFE Components?

PTFE's unique properties—low friction, chemical inertness, and wide temperature range—make it ideal for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. However, designing for its mechanical limitations, like creep, is critical for success.

KINTEK specializes in precision PTFE manufacturing. We help you navigate these trade-offs by offering:

- Custom Fabrication: From prototypes to high-volume orders, we tailor PTFE seals, liners, and labware to your exact needs.

- Expert Guidance: Our team ensures your design leverages PTFE's strengths while mitigating its weaknesses, potentially recommending filled grades for enhanced performance.

Let's optimize your application with the right PTFE solution. Contact our experts today for a consultation.

Visual Guide

Related Products

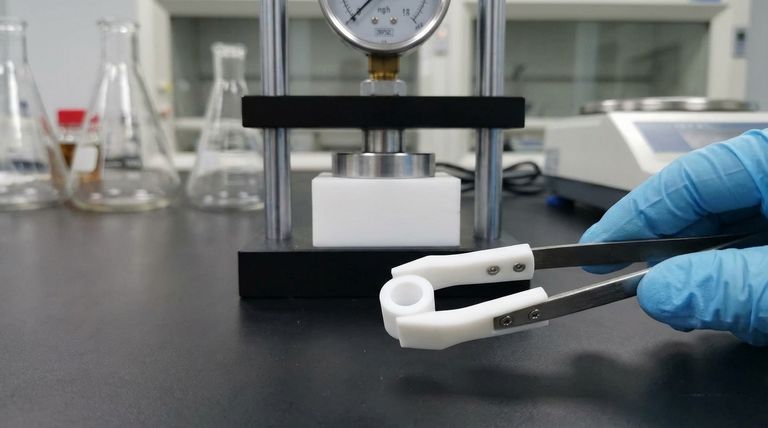

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining