At its core, a PTFE piston guide ring serves one primary purpose: to prevent damaging metal-to-metal contact between a moving piston and the stationary cylinder bore. It acts as a sacrificial, low-friction bearing surface that absorbs lateral forces, protecting the system's most critical and expensive components from wear and premature failure.

The function of a PTFE guide ring extends beyond simple physical separation. It leverages the unique properties of PTFE—low friction, wear resistance, and chemical inertness—to enhance a system's overall efficiency, reliability, and lifespan, especially in demanding or sensitive environments.

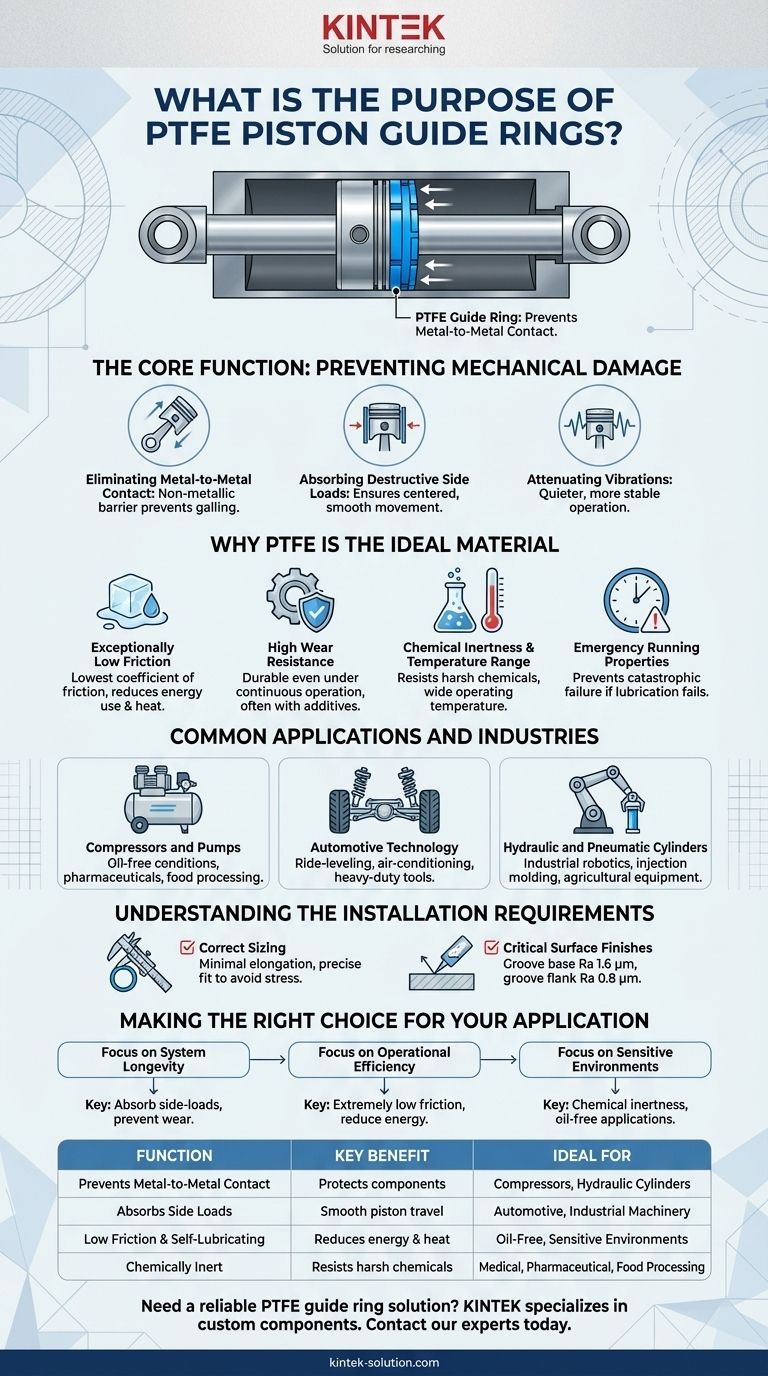

The Core Function: Preventing Mechanical Damage

A piston rarely travels in a perfectly straight line within its cylinder. Side-loads, misalignments, and pressure differentials can force it against the cylinder wall, leading to friction, heat, and scoring. The guide ring is engineered to manage these forces.

Eliminating Metal-to-Metal Contact

The guide ring is a precision-molded component that sits in a groove on the piston. Its outer diameter is designed to slide smoothly along the cylinder bore, creating a non-metallic barrier that prevents galling and seizure.

Absorbing Destructive Side Loads

Any lateral force exerted on the piston rod is transferred to the guide ring. Instead of the piston head grinding against the cylinder wall, the ring bears the load, ensuring the piston remains centered and moves smoothly.

Attenuating Vibrations

The inherent properties of PTFE help to dampen mechanical vibrations. This results in quieter, more stable operation and reduces fatigue on other system components.

Why PTFE is the Ideal Material

The choice of Polytetrafluoroethylene (PTFE) is not arbitrary. Its specific material characteristics make it uniquely suited for this demanding role.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "non-stick" surface ensures excellent gliding behavior, which reduces the energy required to move the piston and minimizes heat generation.

High Wear Resistance

Despite its smooth surface, PTFE is a durable material. Guide rings are often filled with additives like bronze, carbon, or glass to enhance their compressive strength and wear resistance, ensuring a long service life even under continuous operation.

Chemical Inertness and Temperature Range

PTFE is virtually inert to almost all industrial chemicals and solvents. This, combined with its wide operating temperature range, allows these rings to be used in aggressive chemical processing, food and beverage applications, and other harsh environments.

Emergency Running Properties

In systems where lubrication might fail, PTFE provides critical "emergency running" capabilities. Its self-lubricating nature can prevent catastrophic system failure for a short period, allowing for a controlled shutdown.

Common Applications and Industries

The versatility of PTFE guide rings makes them essential components across a vast range of sectors where reliable linear motion is critical.

Compressors and Pumps

They are vital in compressors operating in low-lube or completely oil-free conditions, which is a requirement for industries like food processing, pharmaceuticals, and dentistry. They are also used in vacuum pumps and liquid gas pumps.

Automotive Technology

You will find these rings in automotive systems such as ride-leveling air suspensions, air-conditioning compressors, and even in heavy-duty tools like pneumatic hammer drills.

Hydraulic and Pneumatic Cylinders

From industrial robotics and injection molding presses to agricultural equipment and shock absorbers, PTFE guide rings are a standard component for ensuring the smooth, reliable operation of hydraulic and pneumatic actuators.

Understanding the Installation Requirements

The performance of a PTFE guide ring is heavily dependent on the precision of its installation and the components it interacts with. Simply using the right part is not enough.

The Importance of Correct Sizing

Piston rings must be installed with minimal elongation or stretching. Forcing a ring into a groove it was not designed for can induce stress and lead to premature failure.

Critical Surface Finishes

For optimal performance and seal life, the mating surfaces must be prepared to specific standards. The groove base should have a surface roughness of Ra 1.6 µm, while the more critical groove flank should be smoother, at Ra 0.8 µm. Ignoring these specifications can cause accelerated wear on the ring.

Making the Right Choice for Your Application

Selecting and implementing the right guide ring is a critical step in machine design and maintenance. Your primary goal will determine your key considerations.

- If your primary focus is system longevity: The guide ring's ability to absorb side-loads and prevent wear is its most important function, directly protecting your investment in core components.

- If your primary focus is operational efficiency: The extremely low friction of PTFE is the key benefit, as it reduces energy consumption and heat generation for smoother, more economical operation.

- If your primary focus is operating in sensitive environments: PTFE's chemical inertness and suitability for oil-free applications make it essential for meeting strict standards in the food, medical, and pharmaceutical industries.

Ultimately, this small, often overlooked component is a foundational element of modern mechanical reliability.

Summary Table:

| Function | Key Benefit | Ideal For |

|---|---|---|

| Prevents Metal-to-Metal Contact | Protects expensive components from wear | Compressors, Hydraulic Cylinders |

| Absorbs Side Loads | Ensures smooth, centered piston travel | Automotive Systems, Industrial Machinery |

| Low Friction & Self-Lubricating | Reduces energy consumption and heat | Oil-Free, Sensitive Environments |

| Chemically Inert | Resists harsh chemicals and solvents | Medical, Pharmaceutical, Food Processing |

Need a reliable PTFE guide ring solution? KINTEK specializes in manufacturing high-precision PTFE components, including custom piston guide rings, seals, and labware for the semiconductor, medical, laboratory, and industrial sectors. We ensure your equipment operates with maximum efficiency and longevity. Contact our experts today to discuss your custom fabrication needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech