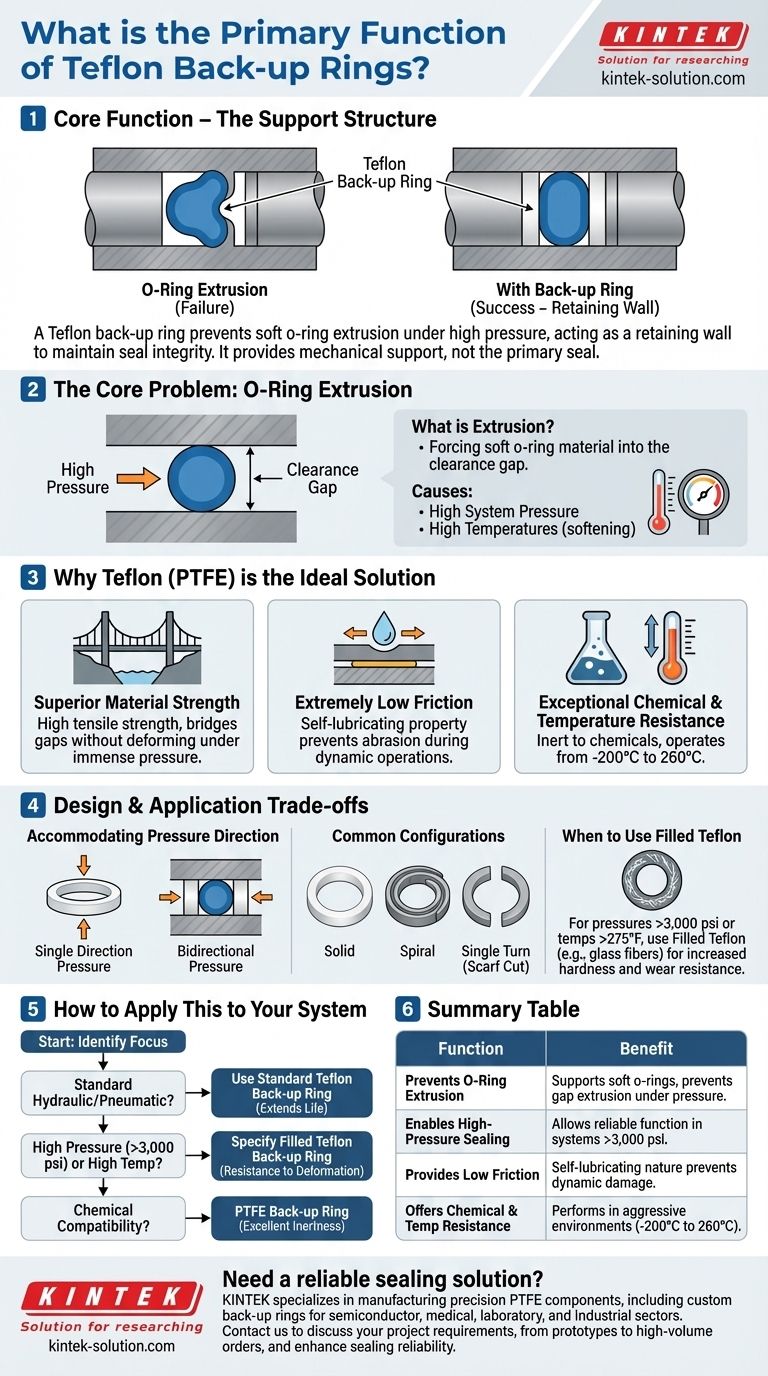

At its core, the primary function of a Teflon back-up ring is to prevent the extrusion of a softer rubber o-ring in a high-pressure sealing system. It acts as a support structure, bridging the gap between sealing surfaces and ensuring the o-ring maintains its shape and integrity under load.

A back-up ring does not provide the seal itself; it provides mechanical support for the primary sealing element—the o-ring. Think of it as a retaining wall that prevents the flexible o-ring from being forced into small hardware gaps under pressure.

The Core Problem: O-Ring Extrusion

What is Extrusion?

In a sealing application, there is a small gap between the moving and stationary metal parts, known as the extrusion gap.

When high pressure is applied, it can force the soft, elastic material of an o-ring into this gap. This process, called extrusion, permanently damages the o-ring, leading to seal failure.

When Does Extrusion Occur?

Extrusion is primarily a function of system pressure. The higher the pressure, the greater the force pushing the o-ring into the clearance gap.

High temperatures can also contribute by softening the o-ring material, making it more susceptible to being deformed and pushed out of place.

Why Teflon (PTFE) is the Ideal Solution

Superior Material Strength

The fundamental principle behind a back-up ring is that it is made from a material significantly harder and more extrusion-resistant than the o-ring it supports.

Teflon (PTFE) has high tensile strength, allowing it to effectively bridge the extrusion gap without deforming, even under immense pressure that would destroy an unsupported o-ring.

Extremely Low Friction

Teflon possesses one of the lowest coefficients of friction of any solid material. This self-lubricating property is critical.

It allows the o-ring to seat properly during installation and prevents it from being abraded or damaged during dynamic operations, such as in a hydraulic cylinder.

Exceptional Chemical and Temperature Resistance

PTFE is virtually inert to most industrial chemicals, acids, and solvents, making it suitable for use in aggressive environments found in chemical processing.

It also maintains its properties over a vast temperature range (from -200°C to 260°C), ensuring reliable performance where standard elastomers would fail.

Understanding Design and Application Trade-offs

Accommodating Pressure Direction

Back-up rings are installed on the low-pressure side of the o-ring.

For systems with pressure from one direction, a single back-up ring is sufficient. In applications with bidirectional pressure, two back-up rings are used, one on each side of the o-ring.

Common Configurations

Various shapes exist to fit specific hardware designs and installation requirements.

Common configurations include Solid, Spiral, and Single Turn (or "Scarf Cut") rings. The choice depends on the groove geometry and whether the ring needs to be stretched for installation.

When to Use Filled Teflon

Standard PTFE is not always sufficient for the most demanding jobs. For severe duty cycles, you may need a filled compound.

Filled Teflon back-up rings, which include additives like glass fibers, are recommended for pressures exceeding 3,000 psi or temperatures above 275°F to further increase hardness and wear resistance.

How to Apply This to Your System

- If your primary focus is standard hydraulic or pneumatic systems: A standard Teflon back-up ring is the most reliable way to extend the life and pressure rating of your o-ring seals.

- If your primary focus is a high-pressure (>3,000 psi) or high-temperature application: Specify a filled Teflon back-up ring to provide the necessary resistance to deformation and wear.

- If your primary focus is chemical compatibility: The inherent inertness of PTFE makes it an excellent choice for back-up rings in chemical processing, aerospace, and food-grade equipment.

Ultimately, incorporating a simple Teflon back-up ring is a critical design choice for ensuring the long-term reliability of any high-performance sealing system.

Summary Table:

| Function | Benefit |

|---|---|

| Prevents O-Ring Extrusion | Supports soft o-rings, preventing them from being forced into hardware gaps under pressure. |

| Enables High-Pressure Sealing | Allows o-rings to function reliably in systems exceeding 3,000 psi. |

| Provides Low Friction | PTFE's self-lubricating nature prevents damage during dynamic operations. |

| Offers Chemical & Temperature Resistance | Performs in aggressive environments from -200°C to 260°C. |

Need a reliable sealing solution for your high-pressure application?

KINTEK specializes in manufacturing precision PTFE components, including custom back-up rings for the semiconductor, medical, laboratory, and industrial sectors. We ensure your seals can withstand extreme pressure, temperature, and corrosive conditions.

Contact us today to discuss your project requirements—from prototypes to high-volume orders—and enhance the reliability of your sealing systems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions