The primary disadvantage of Polytetrafluoroethylene (PTFE) is not related to its in-service performance but to its fundamental processability. Unlike nearly all other thermoplastics, PTFE does not truly melt into a liquid when heated. It instead transitions into a soft, high-viscosity gel that cannot be processed using conventional, high-speed methods like injection molding or standard extrusion, which complicates and often increases the cost of manufacturing.

While PTFE offers unparalleled chemical resistance and the lowest coefficient of friction of any solid, its greatest strength—its extreme molecular stability—is also its greatest manufacturing weakness. This stability prevents it from melting like a typical plastic, forcing the use of specialized and often slower fabrication techniques.

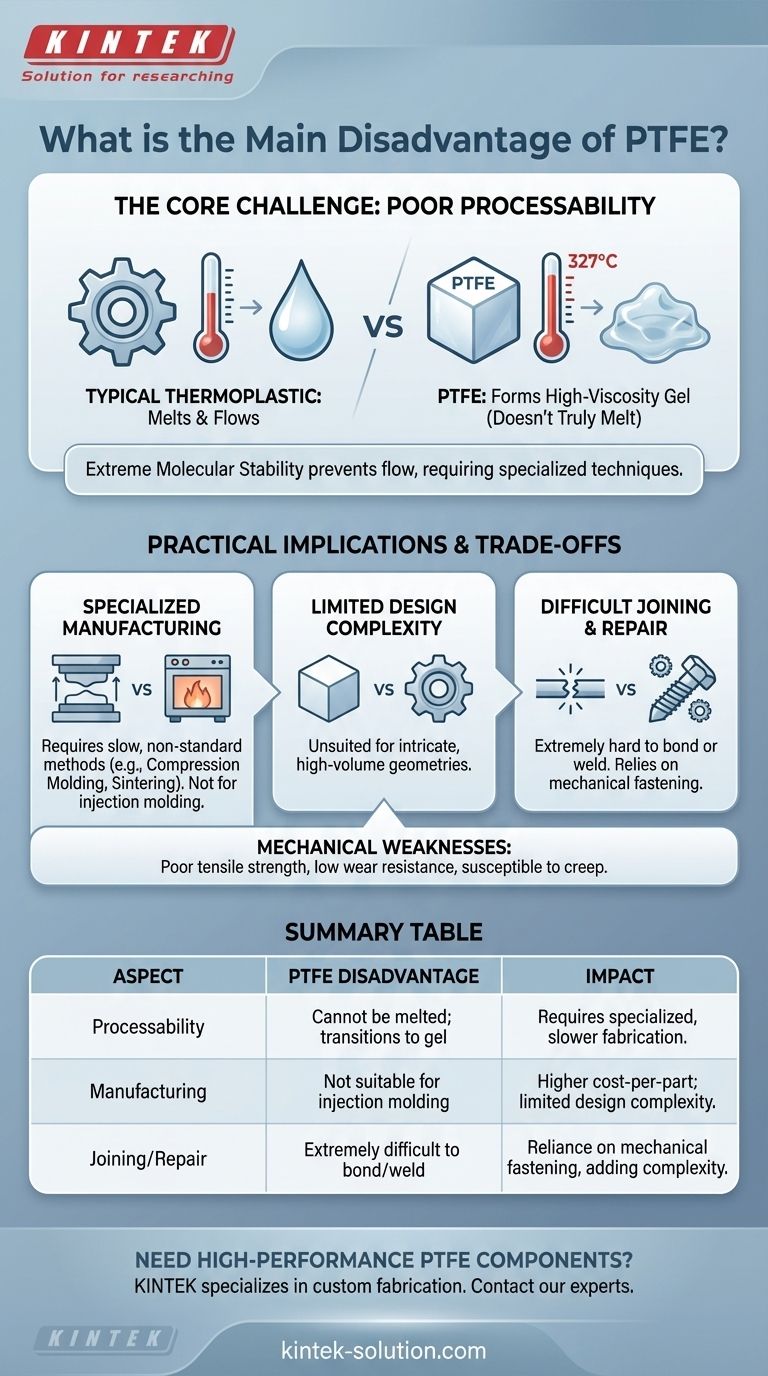

The Core Challenge: Why PTFE Doesn't Flow

The unique properties of PTFE stem from its molecular structure, which is also the source of its primary drawback.

The "Gel State" Transition

When heated above its transition temperature of approximately 327°C (621°F), PTFE does not become a low-viscosity, flowable liquid.

Instead, it enters a translucent gel state. The material becomes soft and formable but remains too viscous to be injected into a complex mold or extruded through a standard die.

Extreme Molecular Stability

The bond between carbon and fluorine atoms in PTFE is exceptionally strong and stable. The fluorine atoms form a tight, protective sheath around the carbon backbone.

This molecular structure is so robust that the material will begin to decompose at very high temperatures before it can ever reach a viscosity low enough for conventional processing.

Practical Implications of Poor Processability

This inability to melt-process has direct, practical consequences for engineers and designers.

Specialized Manufacturing is Required

Because it can't be injection molded, manufacturers must rely on unconventional methods more similar to powder metallurgy than traditional plastics processing.

Common techniques include compression molding and sintering, where PTFE powder is compressed into a shape and then heated to fuse the particles together. Ram extrusion is another method used for producing rods and tubes.

Limitations in Part Complexity

These specialized techniques are generally slower and less suitable for producing intricate, complex geometries with fine details.

This limits the design freedom that is readily available with other engineering plastics like PEEK, nylon, or polycarbonate.

Difficulty in Joining and Repair

The non-stick, non-melting nature of PTFE makes it extremely difficult to bond or weld. Standard solvent or adhesive bonding is ineffective.

While some specialized surface etching processes exist, joining PTFE parts typically relies on mechanical fastening, which adds complexity and potential points of failure to an assembly.

Understanding the Trade-offs

Choosing PTFE means accepting a clear set of compromises that pit elite performance against manufacturing practicality.

Performance vs. Fabricability

You are selecting a material with world-class chemical inertness, an incredibly wide operating temperature range (-200°C to +260°C), and the lowest friction of any solid.

The trade-off is that creating parts from this material will be a more involved, and often slower, process that is unsuited for intricate, high-volume production.

Cost Implications

The specialized equipment, longer cycle times, and often higher scrap rates associated with PTFE processing can lead to a higher cost-per-part compared to components made from melt-processable plastics.

Mechanical Weaknesses

While its processing is the main disadvantage, it's important to note that base PTFE is a relatively soft material. It exhibits poor tensile strength, low wear resistance, and a susceptibility to creep (the tendency to deform permanently under a sustained load).

These mechanical limitations often require the use of filled grades (e.g., glass- or carbon-filled PTFE) to make it suitable for demanding structural or wear applications.

Making the Right Choice for Your Application

To determine if PTFE is the correct material, you must weigh its processing challenges against the demands of your specific environment.

- If your primary focus is extreme chemical inertness or ultra-low friction: The manufacturing complexity of PTFE is a necessary trade-off for its unmatched performance in hostile environments.

- If your primary focus is producing complex, high-volume parts at a low cost: You should immediately explore melt-processable alternatives like FEP or PFA, or other high-performance engineering plastics.

- If your primary focus is structural integrity under a mechanical load: Carefully evaluate PTFE's low strength and tendency to creep, and strongly consider filled grades or alternative polymers for your application.

By understanding that PTFE's defining limitation is its difficult manufacturability, you can properly weigh its incredible performance benefits against the practical realities of fabrication.

Summary Table:

| Aspect | PTFE's Disadvantage | Impact |

|---|---|---|

| Processability | Cannot be melted; transitions to a high-viscosity gel | Requires specialized, slower fabrication methods |

| Manufacturing | Not suitable for injection molding or standard extrusion | Higher cost-per-part and limited design complexity |

| Joining/Repair | Extremely difficult to bond or weld | Reliance on mechanical fastening, adding complexity |

| Mechanical Properties | Soft material with poor wear resistance and creep | May require filled grades for structural applications |

Need High-Performance PTFE Components Despite the Manufacturing Challenges?

At KINTEK, we specialize in overcoming PTFE's primary disadvantage. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get the unparalleled chemical resistance and low friction of PTFE in the precise form you need.

We serve the semiconductor, medical, laboratory, and industrial sectors with precision-manufactured seals, liners, and labware. Don't let processing limitations hold back your design.

Contact our experts today to discuss your project and leverage our specialized manufacturing capabilities.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components