At its core, balancing cost and performance when selecting PTFE packing is about shifting your focus from the initial purchase price to the total cost of ownership. A cheaper, ill-suited packing can lead to frequent failures, costly downtime, and safety risks that far outweigh any upfront savings. The true importance lies in selecting a packing that precisely matches your operational demands, ensuring reliability and long-term value.

The central challenge is not finding the cheapest PTFE packing, but the most cost-effective one. This requires a clear understanding that superior performance characteristics—like durability and chemical resistance—directly translate into lower maintenance, longer service life, and reduced operational costs over time.

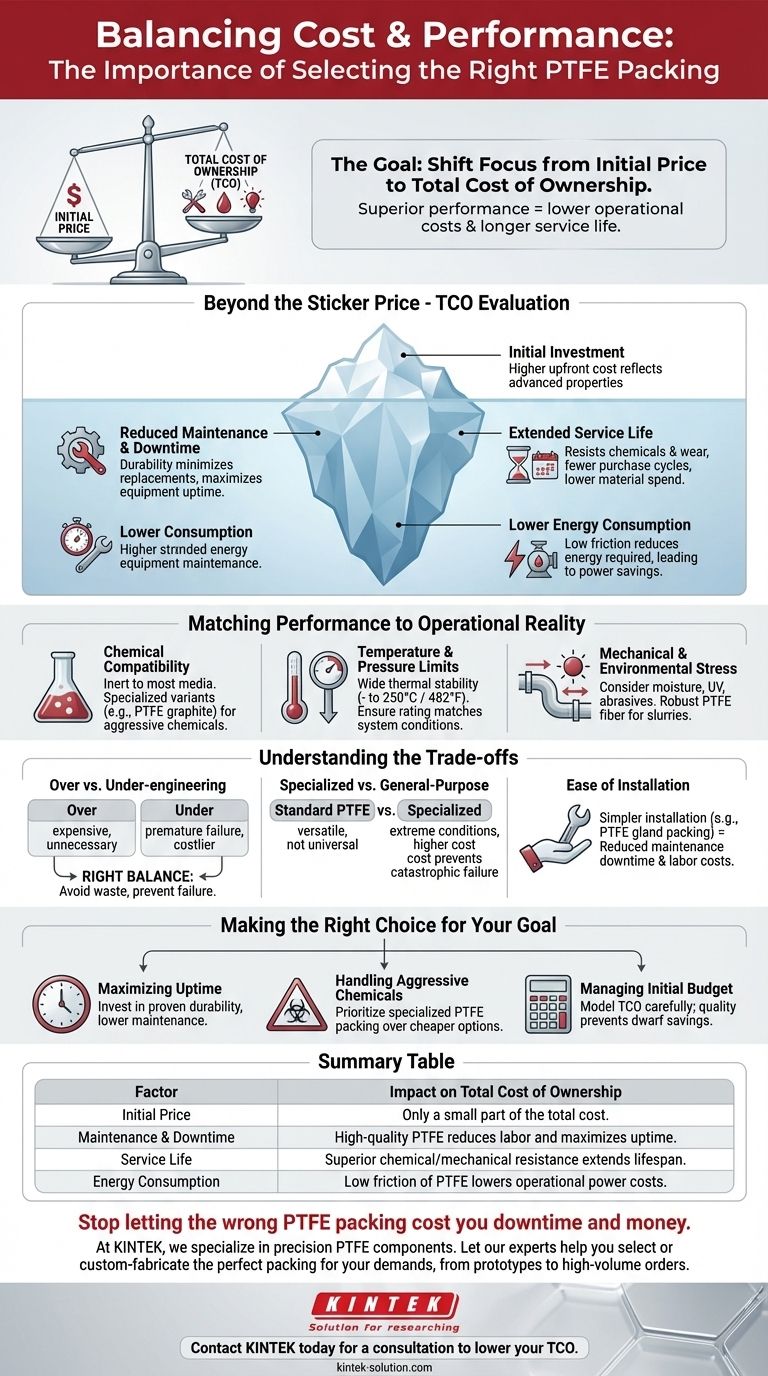

Beyond the Sticker Price: Evaluating Total Cost of Ownership

The initial price tag is only one component of the true cost of an industrial sealing solution. A comprehensive evaluation reveals a more accurate financial picture.

The Initial Investment

PTFE packing often has a higher upfront cost compared to other materials. This reflects its advanced properties and manufacturing process.

Reduced Maintenance and Downtime

High-quality PTFE packing is exceptionally durable. Its longevity minimizes the need for frequent replacement, reducing labor costs and, more importantly, maximizing equipment uptime.

Extended Service Life

Because it resists chemical attack and mechanical wear, a correctly specified PTFE packing can last significantly longer. This means fewer purchase cycles and lower material spend over the life of the asset.

Lower Energy Consumption

PTFE has an extremely low coefficient of friction. In rotating equipment like pumps, this reduces the energy required to overcome drag, leading to tangible savings in power consumption.

Matching Performance to Your Operational Reality

To achieve a low total cost of ownership, you must match the packing's capabilities to the specific stressors of its environment. Over-engineering is wasteful, and under-engineering is a direct path to failure.

Chemical Compatibility

PTFE is nearly chemically inert, making it resistant to most acids, solvents, and bases. However, for exceptionally aggressive media, specialized variants like PTFE graphite packing may be necessary to ensure integrity.

Temperature and Pressure Limits

One of PTFE's key strengths is its wide thermal stability, performing reliably from cryogenic temperatures up to 250°C (482°F). It's critical to ensure your chosen packing is rated for the specific temperature and pressure conditions of your system.

Mechanical and Environmental Stress

The environment outside the pipe or vessel also matters. Consider exposure to moisture, UV light, and abrasive materials. For abrasive slurries, for example, a robust PTFE fiber packing is often the most effective choice.

Understanding the Trade-offs

Making an informed decision requires acknowledging the potential pitfalls and complexities involved.

Over-engineering vs. Under-engineering

The goal is to find the right balance. Selecting a packing far more robust than your application requires is an unnecessary expense. Conversely, choosing a less-expensive, under-specified packing is a common mistake that leads to premature failure.

Specialized vs. General-Purpose

While standard PTFE is highly versatile, it is not a universal solution. Applications involving extreme conditions or specific abrasive media demand specialized—and often more expensive—variants. The higher cost is justified by preventing catastrophic failure.

Ease of Installation

Some packing types, such as PTFE gland packing, are designed for simpler installation. This can be a critical factor, as a faster and easier installation process directly reduces maintenance downtime and associated labor costs.

Making the Right Choice for Your Goal

Your selection criteria should be driven by your most critical operational priority.

- If your primary focus is maximizing equipment uptime: Invest in a packing with proven durability and low maintenance needs, even at a higher initial cost, to minimize replacement cycles.

- If your primary focus is handling aggressive chemicals: Prioritize a specialized PTFE packing with documented resistance to your specific media over a cheaper, general-purpose option.

- If your primary focus is managing a strict initial budget: Carefully model the total cost of ownership; a slightly more expensive packing often prevents a single instance of downtime that would dwarf the initial savings.

Ultimately, the right PTFE packing isn't the cheapest one—it's the one that delivers reliable, long-term performance within your specific operational environment.

Summary Table:

| Factor | Impact on Total Cost of Ownership |

|---|---|

| Initial Price | Only a small part of the total cost. |

| Maintenance & Downtime | High-quality PTFE reduces labor and maximizes uptime. |

| Service Life | Superior chemical/mechanical resistance extends lifespan. |

| Energy Consumption | Low friction of PTFE lowers operational power costs. |

Stop letting the wrong PTFE packing cost you downtime and money.

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We understand that the true cost of a seal isn't its price tag, but its performance in your specific application.

Let our experts help you select or custom-fabricate the perfect PTFE packing to match your operational demands, from prototypes to high-volume orders. Achieve the ideal balance of cost and performance to ensure reliability and maximize your return on investment.

Contact KINTEB today for a consultation and see how our precision PTFE solutions can lower your total cost of ownership.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection