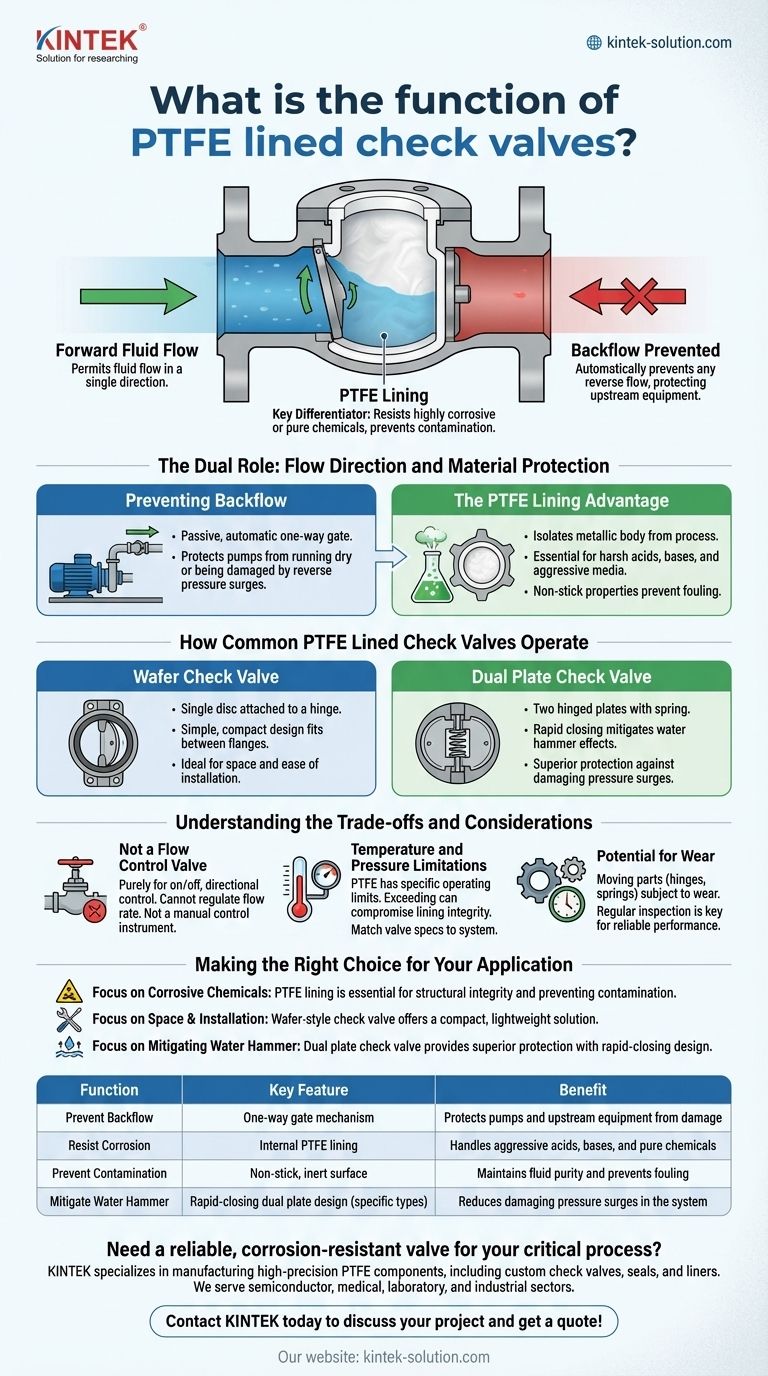

The primary function of a PTFE lined check valve is to permit fluid flow in a single direction while using its specialized lining to resist highly corrosive or pure chemicals. This dual-purpose design ensures that fluid moves only forward, automatically preventing any reverse flow that could contaminate a process or damage critical upstream equipment like pumps and pipelines.

While any check valve is designed to prevent damaging backflow, the polytetrafluoroethylene (PTFE) lining is the key differentiator. This feature makes the valve essential for systems handling aggressive media where standard metallic or elastomeric components would quickly corrode and fail.

The Dual Role: Flow Direction and Material Protection

A PTFE lined check valve serves two distinct but interconnected purposes. It manages the physical direction of flow while simultaneously providing a chemical barrier to protect the valve's structural components.

The Core Mechanic: Preventing Backflow

At its heart, a check valve operates as a one-way gate. It is a passive, automatic valve that requires no external actuation to function.

When fluid moves in the intended direction, the pressure opens the valve's internal mechanism. If the flow stops or attempts to reverse, this back-pressure forces the mechanism to seal shut, preventing any backflow. This is critical for protecting pumps from running dry or being damaged by reverse pressure surges.

The Critical Advantage: The PTFE Lining

The defining feature is its internal lining made of PTFE, a fluoropolymer known for exceptional chemical resistance.

This lining isolates the valve's metallic body from the process fluid. It is indispensable in applications involving harsh acids, bases, or other corrosive chemicals that would rapidly degrade standard materials. Its non-stick properties also prevent media from adhering to and fouling the valve's internal surfaces.

How Common PTFE Lined Check Valves Operate

Different designs achieve the same goal of preventing backflow, but their mechanisms are suited for different conditions.

The Wafer Check Valve

A wafer-style check valve uses a single disc attached to a hinge. Forward flow pushes the disc open, allowing fluid to pass.

When flow reverses, the disc swings shut against its seat, creating a seal. Their simple, compact design allows them to be installed directly between two pipe flanges, making them easy to fit into existing systems.

The Dual Plate Check Valve

This design, also known as a dual-door check valve, uses two half-circle plates (doors) hinged in the center.

The plates are held shut by a spring. Forward flow pressure overcomes the spring tension and opens the plates. When flow reverses, the back-pressure and the spring action cause the plates to snap shut quickly. This rapid closing helps mitigate the effects of water hammer, a damaging pressure surge caused by a sudden stop in fluid momentum.

Understanding the Trade-offs and Considerations

While highly effective, choosing the right valve requires understanding its operational limits and proper application.

Not a Flow Control Valve

A check valve is purely for on/off, directional control. It cannot be used to throttle or regulate the rate of flow.

For flow regulation, a different type of valve, such as a PTFE lined butterfly or ball valve, is required. A check valve is an automatic safety device, not a manual control instrument.

Temperature and Pressure Limitations

PTFE has a specific operating temperature and pressure range. Exceeding these manufacturer-specified limits can compromise the integrity of the lining, leading to valve failure.

It is crucial to match the valve's specifications to the system's maximum operating temperature and pressure to ensure safety and longevity.

Potential for Wear

Like any mechanical device, the moving parts—such as hinges and springs—are subject to wear over time. The effectiveness of the seal depends on the condition of the disc and the seat. Regular inspection, especially in high-cycle or abrasive applications, is key to reliable performance.

Making the Right Choice for Your Application

Selecting the correct valve requires aligning its design with your primary operational goal.

- If your primary focus is handling highly corrosive chemicals: The PTFE lining is the essential feature, ensuring the valve's structural integrity and preventing process contamination.

- If your primary focus is space and ease of installation: A wafer-style check valve offers a compact, lightweight solution that fits easily between existing pipe flanges.

- If your primary focus is mitigating water hammer: The rapid, spring-assisted action of a dual plate check valve provides superior protection against damaging pressure surges.

Ultimately, selecting the correct PTFE lined check valve means matching its specific design strengths to the unique chemical and mechanical demands of your system.

Summary Table:

| Function | Key Feature | Benefit |

|---|---|---|

| Prevent Backflow | One-way gate mechanism | Protects pumps and upstream equipment from damage |

| Resist Corrosion | Internal PTFE lining | Handles aggressive acids, bases, and pure chemicals |

| Prevent Contamination | Non-stick, inert surface | Maintains fluid purity and prevents fouling |

| Mitigate Water Hammer | Rapid-closing dual plate design (specific types) | Reduces damaging pressure surges in the system |

Need a reliable, corrosion-resistant valve for your critical process?

KINTEK specializes in manufacturing high-precision PTFE components, including custom check valves, seals, and liners. We serve the semiconductor, medical, laboratory, and industrial sectors, ensuring your equipment is protected from the most aggressive chemicals.

Our expertise in custom fabrication—from prototypes to high-volume orders—guarantees a perfect fit for your specific application requirements.

Contact KINTEK today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- In which industries are mechanical seals with PTFE rings commonly used? Essential for Harsh Chemical & High-Temp Environments

- What manufacturing methods are used to produce PTFE gaskets? Choose the Right Process for a Perfect Seal

- What types of equipment commonly use ePTFE gaskets? Solve Your Toughest Sealing Challenges

- What should be considered when milling Teflon? Master Machining for Precision PTFE Parts

- How is virgin PTFE processed into sheets? A Guide to Purity, Performance, and Trade-offs

- What advantages do custom PTFE parts offer for industrial efficiency? Boost Uptime & Cut Costs

- What are some industrial applications of PTFE lip seals in extreme temperatures? Ensuring Reliability from Cryogenics to High Heat

- What are some tips for successfully machining PTFE? Master Precision Cuts for Soft, Heat-Sensitive Material