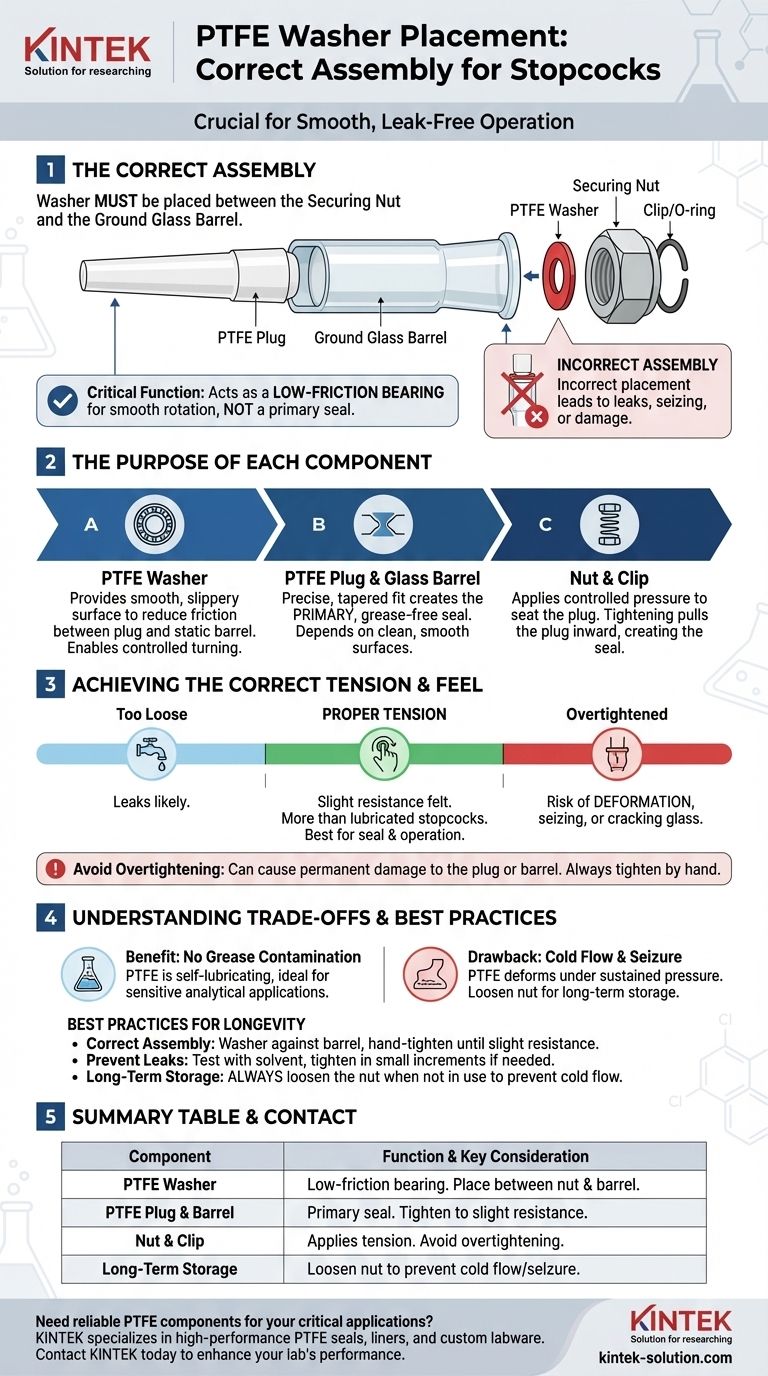

In a standard PTFE stopcock assembly, the washer is always placed between the securing nut and the end of the ground glass barrel. This positioning is critical because the washer acts as a low-friction bearing, allowing the plug to turn smoothly against the stationary glass barrel when the assembly is tightened.

The PTFE washer's primary function is not to create a seal, but to enable smooth, controlled rotation. Proper placement ensures the stopcock operates reliably without seizing, while incorrect placement can lead to leaks or damage to the glassware.

The Purpose of Each Component

Understanding how each part contributes to the function of the stopcock is key to correct assembly and use. The system is designed for a precise, lubricant-free seal.

The PTFE Washer: A Low-Friction Bearing

The washer’s sole purpose is to provide a smooth, slippery surface. It sits between the parts that create turning friction: the plug assembly and the static glass barrel.

This allows you to tighten the nut to create a seal without locking the plug in place. Without the washer, the friction would be too high, making the stopcock difficult to turn or causing it to seize.

The Plug and Barrel: The Sealing Surfaces

The actual seal is formed by the precise, tapered fit of the PTFE plug inside the ground glass barrel.

When the nut is tightened, it pulls the tapered plug firmly into the barrel, creating a leak-proof barrier along their contact surfaces. The quality of this seal depends on the clean, smooth surfaces of both components.

The Nut and Clip: Applying Tension

The threaded nut and its corresponding clip or o-ring are responsible for applying controlled pressure to the assembly.

As you tighten the nut, it pulls the entire plug assembly inward, seating the plug more firmly within the barrel. The PTFE washer ensures this tightening action doesn't prevent the plug from rotating.

Achieving the Correct Tension and Feel

The goal is to create a seal that is tight enough to prevent leaks but loose enough to allow for smooth operation.

What "Properly Tightened" Feels Like

A correctly assembled PTFE stopcock will feel slightly resistant to turning. The reference point is that it should offer more resistance than a traditional, lubricated glass stopcock.

If it turns with zero resistance, it is likely too loose and will leak. If it requires significant force, it is overtightened.

The Risk of Overtightening

Applying excessive force with the nut can cause significant problems. It can deform the soft PTFE plug, creating permanent flat spots that prevent a proper seal.

In severe cases, overtightening can score or even crack the ground glass barrel, permanently ruining the piece of equipment. Always tighten by hand and with care.

Understanding the Trade-offs: PTFE Properties

PTFE stopcocks eliminate the need for grease, which can contaminate reagents. However, the material properties of PTFE introduce a different set of considerations.

The Benefit: No Grease Contamination

Because PTFE is inherently low-friction or "self-lubricating," it does not require vacuum grease to turn smoothly or create a seal. This is its primary advantage over older all-glass designs, especially in sensitive analytical or organic chemistry applications.

The Drawback: Cold Flow and Seizure

PTFE is a relatively soft material that can deform under sustained pressure, a phenomenon known as cold flow.

If a stopcock is stored for long periods in a fully tightened state, the PTFE plug can slowly conform to the shape of the barrel, even expanding into the bore holes. This can cause the plug to seize, making it impossible to turn without risking damage.

Best Practices for Assembly and Longevity

Following a few simple rules will ensure your stopcock functions reliably and lasts for years.

- If your primary focus is correct assembly: Place the PTFE washer directly against the end of the glass barrel, then secure the assembly by hand-tightening the nut until you feel slight turning resistance.

- If your primary focus is preventing leaks: After initial assembly, test with a solvent. If a leak is present, tighten the nut in very small increments until the leak stops. Do not overtighten.

- If your primary focus is long-term storage: Always loosen the nut on the stopcock when it is not in use. This releases the pressure on the plug, preventing cold flow and seizure.

By understanding the role of each component, you can ensure your equipment remains a reliable tool for precise control.

Summary Table:

| Component | Function | Key Consideration |

|---|---|---|

| PTFE Washer | Low-friction bearing for smooth rotation | Place between securing nut and glass barrel |

| PTFE Plug & Glass Barrel | Creates the primary, grease-free seal | Tighten nut until slight resistance is felt |

| Nut & Clip | Applies tension to seat the plug | Avoid overtightening to prevent damage |

| Long-Term Storage | Prevents PTFE cold flow and seizure | Always loosen the nut when not in use |

Need reliable, precision-made PTFE components for your critical applications?

KINTEK specializes in manufacturing high-performance PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment operates with the leak-free reliability and smooth control described in this article.

Whether you need standard parts or custom fabrication from prototypes to high-volume orders, we prioritize precision and durability.

Contact KINTEK today to discuss your PTFE component needs and enhance your lab's performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency